4 - SRP Player - Preview Results

This is where you can see what the machine will cut, and estimate how

long it will take. At this point it is your responsibility to ensure that you

are not telling the machine to cut deeper than it is able.

Steps:

1) Press “Preview Cutting” and wait for SRP Player to simulate your job.

2) As you watch the simulation, consider the deepest parts of your model. Note that the depth

of vertical walls and deep pockets is limited by the length of the bit. The maximum depth

at which a ¼” diameter tool can cut without the gantry colliding with your material is 1.7”

and the maximum depth at which a 1/8” tool can cut without such a collision is .9” It is your

responsibility to ensure that the bit is at least as far out of the collet as your specified depth.

You need to check this value in order to prevent a collision between the collet or gantry and the

material to be milled. Be aware that this is different from the amount of material the tool can

cut in one pass-- that’s referred to as the “step-down” and it is determined by the flute length

and chip load given a specific material.

3) If you need to reduce the depth of your model you can do so by either a) rescaling your

geometry (under Model Size and Orientation), or b) specifying that the Roland MDX 40-A ignore

the lower part of your model in under Tool Path Depth (see Step 3.5).

4) If you need to reduce the amount of time it is taking to cut your model, consider using a

larger bit in step 3.6, a larger step-over for your Finish Passes in step 3.8, selecting a faster

cutting time over quality in step 2, or (if you are using multiple finish-passes) eliminating

redundant finishing passes in step 3.3.

Special Note: It is possible to use MasterCAM to generate code, which may increase the

efficiency and/or allow more flexibility in determining tool lengths.

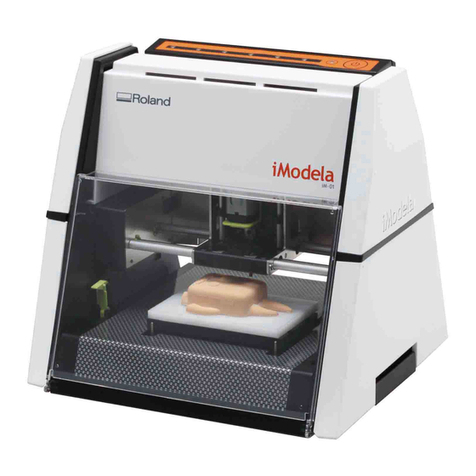

Maximum depth

at which it is possible

to cut into the material

is defined by the

distance the cutting bit

sticks out of the collet.

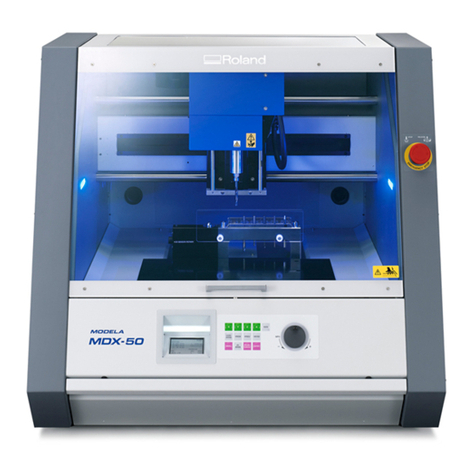

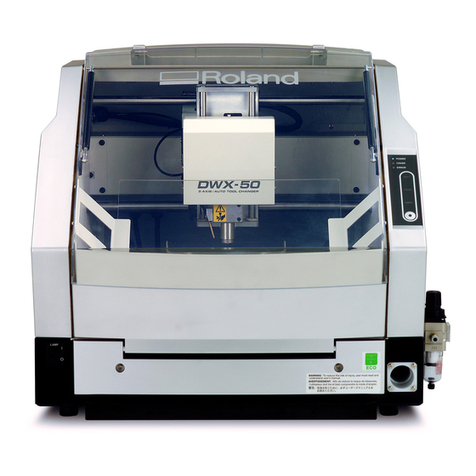

VPanel is the software that allows you to interact with the mill. You’ll

need to use it as you fasten your material, install your endmill and

“home” (define the origin) the axes.

Steps:

1) Moving the gantry. The red arrows will move in X (left-right), the green arrows will move in

Y (back-forth). The movement in Y is inverted because the X axis is stationary, so move the Y

axis as if you wanted to move the bit around your material. The blue arrows control movement

in Z (up-down), these controls are duplicated in solid orange on the front of the machine itself.

As you move you can control the speed using the step sizes. Use caution when moving at high

speed, because if you collide with anything you might damage the bit, your material or the

machine and you will need to re-zero the X, Y and Z axes.

2) Overrides allow you to adjust the spindle speed and feed rate after you’ve begun milling.

The machine’s maximum spindle speed is 8000 rpm, and the maximum feedrate is 120 inches

per minute, or 3000 mm/min. Overrides are also limited to 100% of the maximum specified in

the job, so you can easily reduce speed, but you cannot increase speed at this stage.

3) Origin Controls are for communicating where the machine should place the origin, or the

point (0,0,0). Use the top of your stock as zero for Z, and the center of your stock for zero in X-Y.

4) Readout will tell you where the tool tip is, according to the location your provide as the

origin. It will also tell you how fast the bit is spinning (rotations per minute) and how fast it is

moving (inches or mm per minute).

5) Send to Cut is where you access preferences, and tell the machine to start or stop cutting.

6) MDX-40A controls allow you to pause the job mid-way. Press “View” to do this, the spindle

will stop and the gantry will retract. If you press and hold “View”, it will resume cutting. Green is

the power button, and the orange buttons allow you to move the spindle up and down

7) Emergency Stop will stop the machine immediately and cause you to lose all work you’ve

done so far. It is not possible to resume a job after an emergency stop.

1

2

3

4

5

6

7

4.1 - 4.3 VPanel - Prepare for cutting