Roland RML-1 Instruction Manual

Other Roland Power Tools manuals

Roland

Roland PNC-3100 CAMM-3 User manual

Roland

Roland MODELA PRO II series Use and care manual

Roland

Roland DWX-51D User manual

Roland

Roland CAMM-3 PNC-300 User manual

Roland

Roland ZAT-540 User manual

Roland

Roland MODELA Pro MDX-650A User manual

Roland

Roland CAMM-3 PNC-3200 User manual

Roland

Roland DWX-51D User manual

Roland

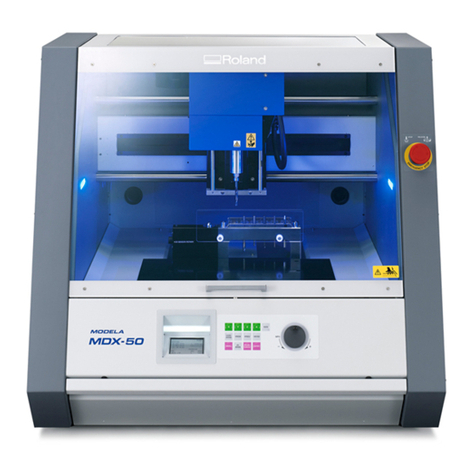

Roland MODELA MDX-50 User manual

Roland

Roland CAMM-3 PNC-3200 User manual

Roland

Roland MODELA Pro ZCL-650A User manual

Roland

Roland monoFab SRM-20 User manual

Roland

Roland CAMM-3 PNC-3200 Operating and maintenance manual

Roland

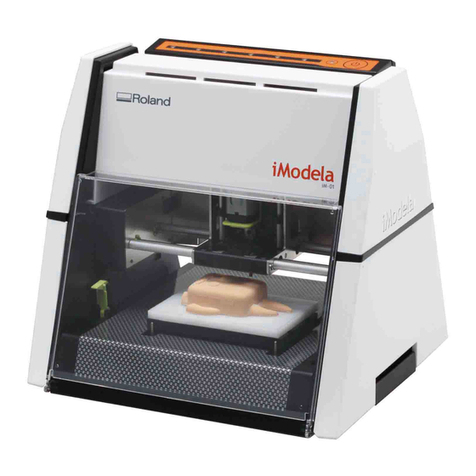

Roland iModela iM-01 User manual

Roland

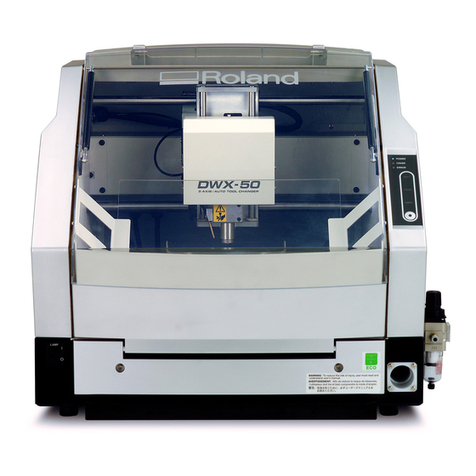

Roland DWX-50 Operating manual

Roland

Roland MDX-40A User manual

Roland

Roland monoFab SRM-20 User manual

Roland

Roland MODELA Pro II ZCL-540 User manual

Roland

Roland MDX-40A User manual