10 S-19-01-1211-U0001 V4.3

‧

Periodically check the ultrasonic insert for ear

ith the Insert Efficiency Indicator.

‧

The use of a saliva ejector or High Volume

Evacuator (HVE) is recommended during all

procedures.

‧

Set the System's Po er Adjustment knob to the

lo est po er setting for the application and the

selected insert.

‧

If ater leakage found in handpiece, replace

sleeve or o-ring on handpiece cable assembly to

eliminate.

9. Patient Comfort Considerations

Reasons for sensitivity

‧

Incorrect tip placement. Point should be directed

a ay from root surfaces.

‧

Not keeping tip in motion on tooth. Do not allo

the insert to remain in a static position on any one

area of the tooth. Change the insert's path of

motion.

‧

Applying pressure. Use extremely light grasp and

pressure, especially on exposed cementum.

‧

If sensitivity persists, decrease po er setting

and/or move from the sensitive tooth to another

and then return.

Section 10: System Maintenance and Care

Daily Maintenance

It is recommended that you perform the follo ing

maintenance procedures to help minimize bio-film

formation in the ater path of your ELiTEDENT

®

ultrasonic scaler hich could affect the ater flo to

the ultrasonic insert, and scaling performance.

Start-Up Procedures at the beginning of the

day:

1. Open the manual shut-off valve on the dental

office ater supply system.

2. Set the Po er Control knob to minimum setting.

3. Set the Water Control knob to maximum.

4. Hold the Handpiece ( ithout an insert installed)

upright over a sink or drain. Activate the Foot

Control and flush the ater line for at least 2

minutes.

5. Place a sterilized insert into the Handpiece and

set the ater control knob to your preferred

operating position.

Between Patients:

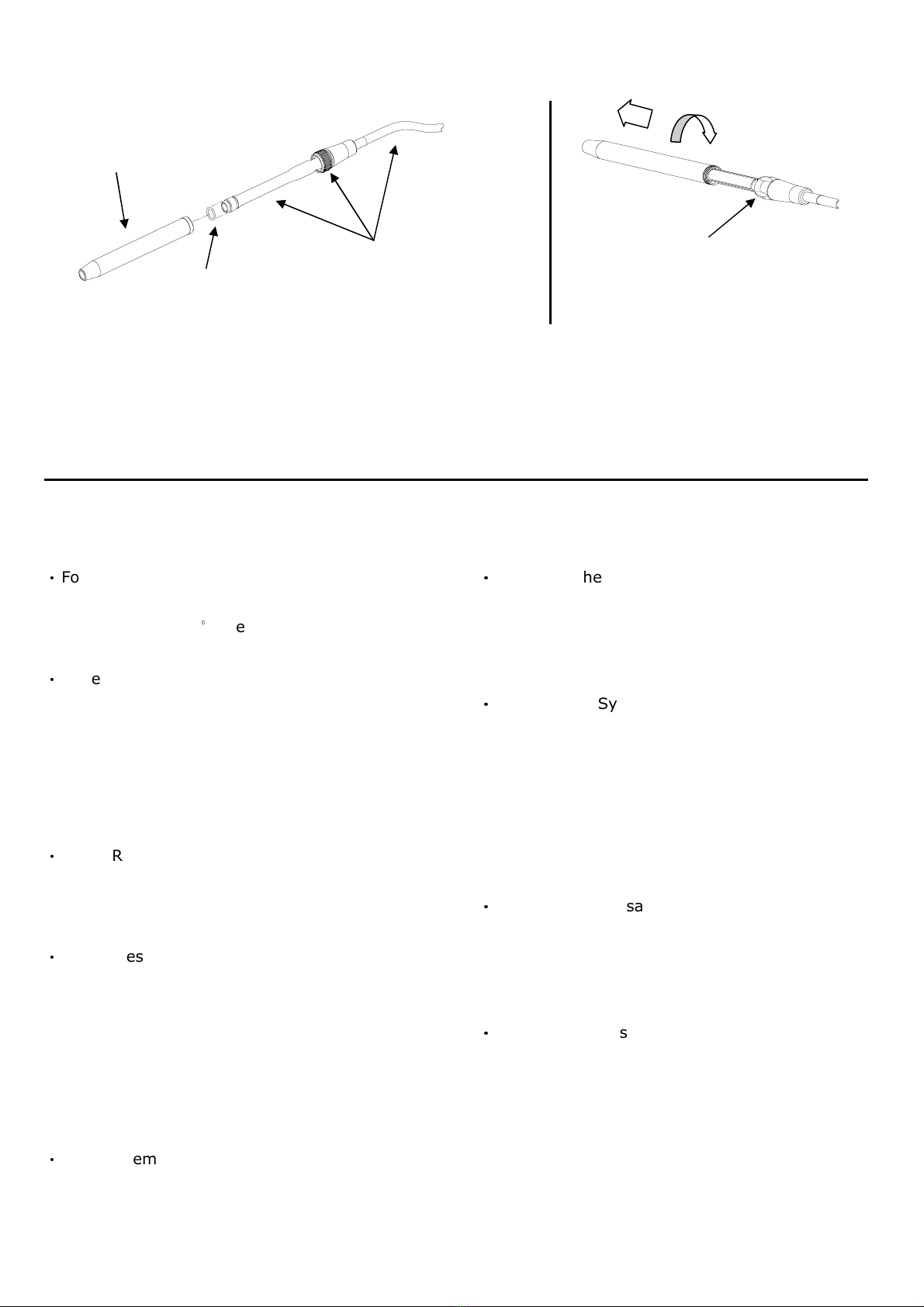

1. Remove ultrasonic insert and handpiece sleeve

used, clean and sterilize.

2. Clean and disinfect the surfaces of the cabinet,

Handpiece cable assembly*, control knobs by

applying an approved non-immersion type

disinfectant solution* carefully follo ing the

instructions provided by the disinfectant solution

manufacturer. To clean system, generously spray

disinfectant solution on a clean to el and ipe all

surfaces. Discard used to el. To disinfect system,

generously spray disinfectant on a clean to el

and ipe all surfaces. Allo disinfectant solution

to air dry. Do not spray disinfectant solution

directly on the ultrasonic scaler.

3. Place a sterilized handpiece sleeve. Set po er to

minimum. Hold the handpiece over a sink or drain

and flush the ater line at maximum ater flo

for 30 seconds.

4. When ready, place a sterilized insert into the

handpiece.

5. Please consider use a FDA approved sheath to for

the cable and entire handpiece or at least to cover

the handpiece from the fastening ring to cable

hen sleeve is sterilized bet een patients.

Shut-Down Procedures at the end of the day:

1. Remove ultrasonic insert and handpiece sleeve

used, clean and sterilize.