Understanding these concepts / conventions will help guide you

through the instructions.

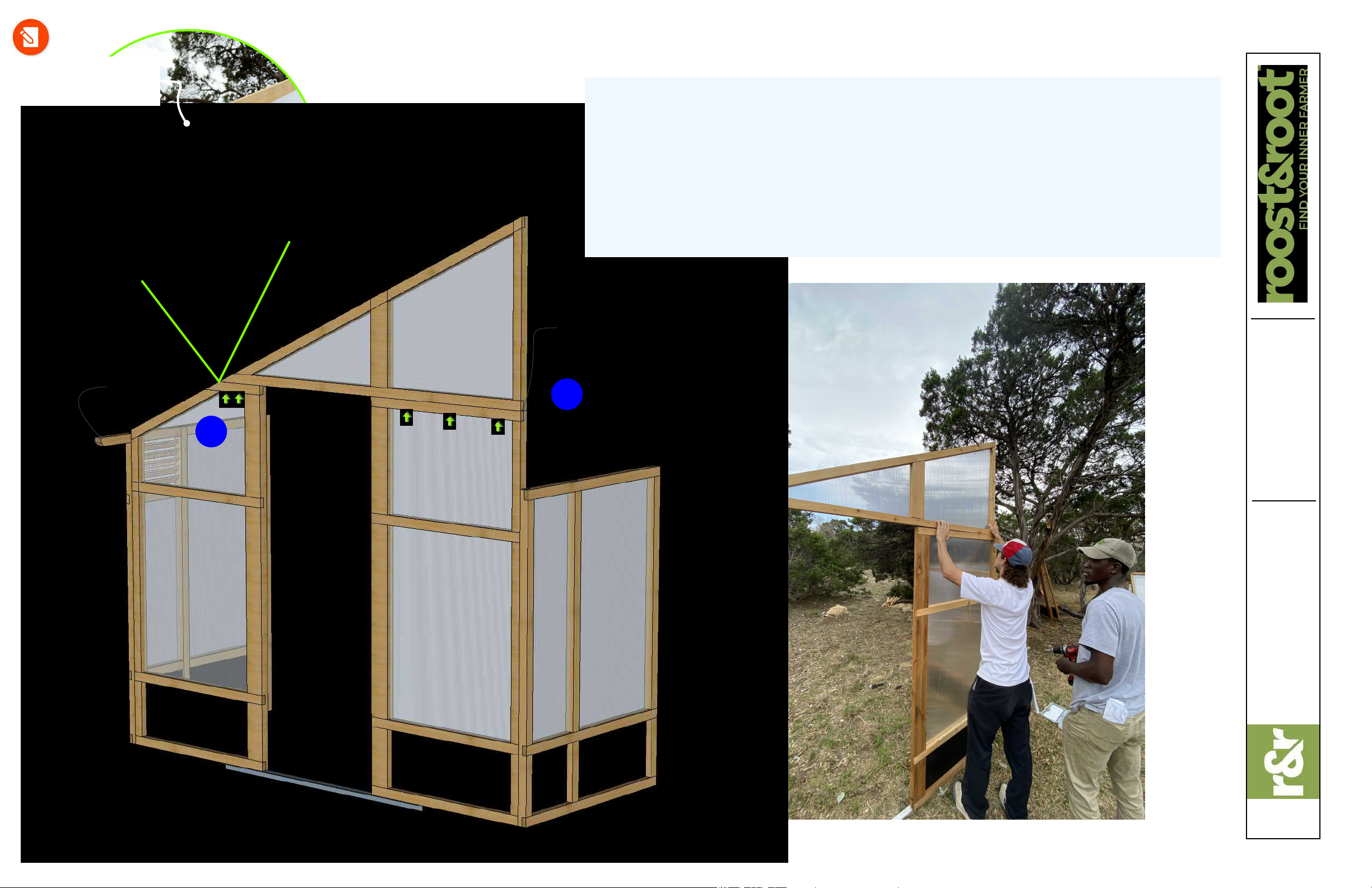

�Mating edges of parts to be flush and tight (when called for) will

keep measurements in tolerance as the greenhouse grows in

size. By flush we mean to align edges.

�Having a flat area is required for the greenhouse to assemble

properly. Any humps will telegraph into wall straightness.

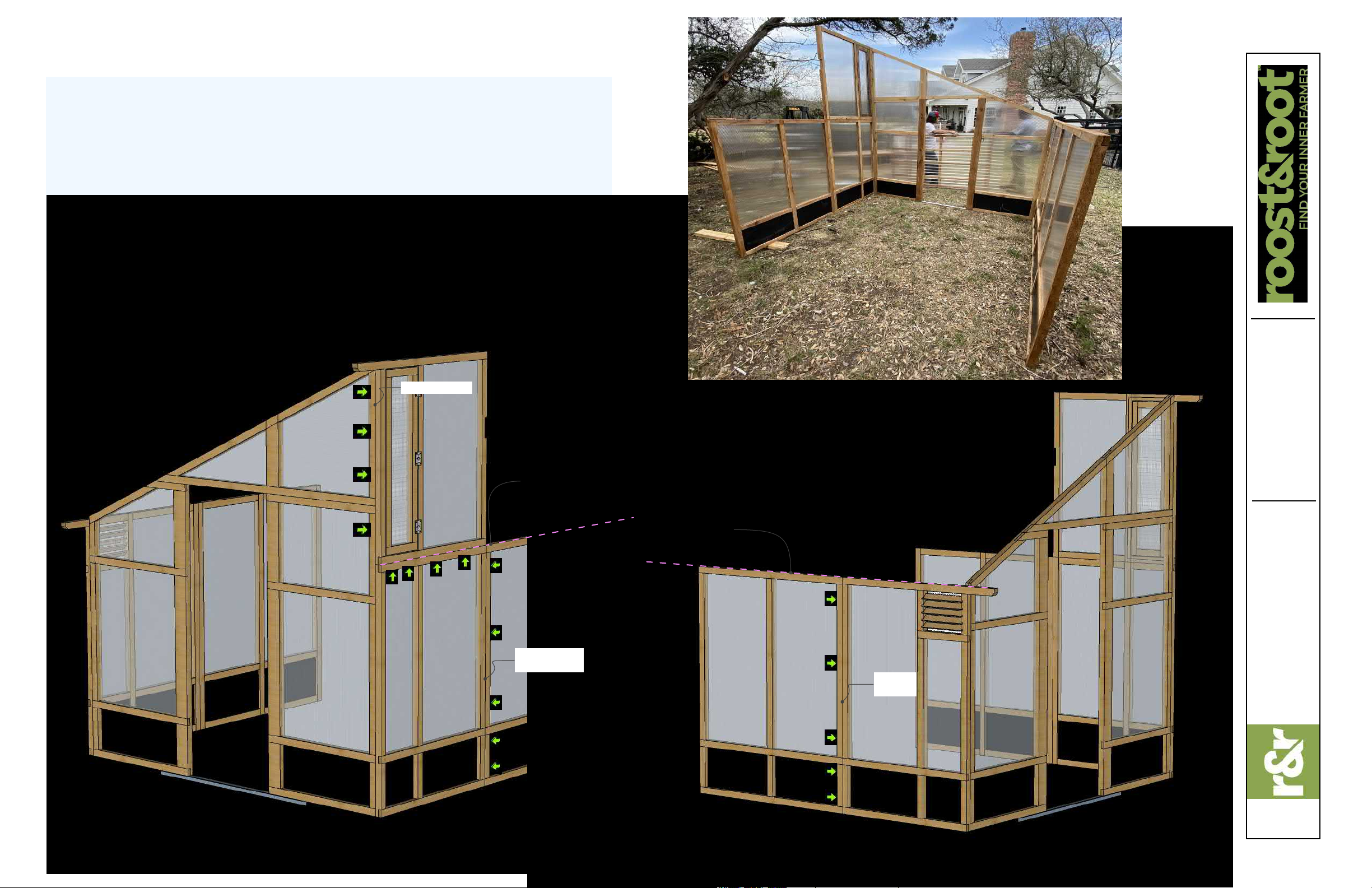

�We estimate about 12 man hours (6-8 hours for 2 people) of

ordinary skills to assemble. Two strong people are required for

several steps.

�You will need a drill (preferably cordless) a tape measure and a

hammer. Everything else is provided.

�Drive screws only deep enough to hold parts tight and not bury

the heads too deeply as water will sit in the divots and it may

cause softening of the wood and prematurely loosen screws. It

will also greatly decrease your ability to easily disassemble a

part if needed.

�You may end up directly driving in a screw. The provided

screws are very aggressive and will drive with no pre-drilled

hole. Keep screw entry points in the meat of the wood and not

too close to edges. Screws in knots or close to edges should

be pre-drilled.

�Rough cedar may have knots, cracks or frays that are normal.

We cull and cut around most imperfections we deem

structurally problematic during fabrication. If you get a piece

that you feel is not beautiful, please let us know so we can

address your concern. Cedar naturally varies quite a bit.

�We hand fabricated your greenhouse with human carpenters.

We work really hard to not make mistakes. On the rare

occasion that we either misfabricated a part, a part was

damaged in shipping, or we forgot to package a needed part,

contact us and we will ship out a replacement part for you at no

cost.

�It is common for rough cut cedar to vary in size by up to 1/8

inch and to shrink and swell by up to 1/8 inch when wet and

dry. It is normal for edges to not perfectly line up and shrink

and swell during periods of heavy rain or snow cover.

Any building material can have sharp edges. We attempt to

knock off sharp edges when possible during fabrication. You

must be the final determiner of sharp edges. A standard file

from your hardware store, or snips can be used to make

edges to your standards. You may choose to wear a pair of

work gloves while assembling this product for extra

protection. Wood, being what it is, can also have splinters.

Spending the time up front to identify all the parts and lay

them all out will pay off in the long run and make assembly

go more smoothly. The instructions are intended to be

read in page order as the information builds in that way,

then referenced during assembly. Pre-reading the

instructions will help immensely.

The roof has been load tested with more than

#1000 of weight and a #200 man. But we do not

intend on you being up on the roof. It will not

reach its full strength until after full assembly and

at 25° it is extremely steep. We use a unique

preassembled scissor style folding roof design that

allows you to place the roof from the ground. It

will take two strong people... maybe 3 if you're

not comfortable working with weight. If you decide

to work from a ladder, be mindful of your balance

and weight load.