ELECTRICAL CONNECTIONS

Check with your local utilities for electrical codes that apply

in your area If there are no local codes, Ihe National

Electrical Code, ANSI/NFPA No. 70-1987 must be followed

You can get a copy by wnting

National Fire ProtectIon Association

Batterymarch Park

Oulncy, MA 02269

An adequate electrical supply and outlet must be used to

operate the electrical parts of your oven The oven cord has

a ‘three prong plug and must be used with a properly

grounded three hole outlet with standard 120 volt 60 Hertz

AC household current.

Install the electrical outlet below the oven on the right side

It should be easily reached through cabinet doors below the

oven See Figure 5

The preferred method of electrlcal hook-up IS shown In Fig

2 Ii you do not have a grounded (three hole) outlet, have a

qualified electrician change your old outlet or Install a new

lone

.4 grounding adapter plug may be used to convert a two hole

outlet to a three hole outlet until a grounded outlet can be

installed See Figure 3 This should be done only temporar-

sly and only

11

the two hole outlet

IS

properly polarized and

grounded Have a quaIlfled electrician test the outlet to be

sure it meets all requirements

Always unplug the oven cord before making any electri-

cal repairs to the oven. When unplugging the oven,

always grasp the plug, never the cord. Never use an

extension cord to connect the oven to the electrical

supply.

A

Do not under any circumstances cut or

removegrounding prong from oven cord.

Failure to provide proper polarization

may create a hazardous condition.

P!~.J(; ~YITH GROUND PRONG

PG:)PERLY POLARIZED A’lG

GR3clNDED RECEPTACLE

POLARIZED RECEPTACLE

PROPERLY GROUNDED

METAL EYELEl

CiFWND

RECEPTACLE

PLATE

MOUNTING

SCREW

Fig. 2 Fig 3

PREFERRED METHOD TEMPORARY METHOD

GAS CONNECTIONS

Do not operate the burners of this oven

burner orifices for L.P. gas usage.

You must follow local codes when InstallIng your built-in

oven Check with your local utiltties for codes and ordt-

nances that apply in your area If there are no local codes.

you must follow the Natlonal Fuel

Gas

Code ANSI/Z223 l-

1988 and Addenda 2223

12

1987 You can get a copy by

wrltlng American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

If the oven ISto be Installed In a mobile home, the lnstallatlon

musl conform to the MdnufaClured Home Construction and

Safety Standard, Title 24CF-R part 3280 (formerly the Fed-

eral Standard for Mobile Home Construction and Safety,

Title 24, HUD part 280) or, when not applicable, the standard

for Manufactured Home Installations 1982 (Manufactured

Home Sites. Communitres and Set-ups) ANSI A225l-

1984, or with local cooes You can get a copy of the Federal

Standard by wrlllng

Ofllce of Mobile Home Standards

tHUD BulldIng

451 7th Street, S W

Washington. D C 24010

The gas suppiy must be shut off before removing an old oven

and stay off until the hookup of the new oven is finished You

should know where your main gas shut off valve

IS

located

N.ever reuse an old connector when installing a new

oven.

Be sure no stralri

IS

put on the connecting line assembly To

prevent gas leaks put a pipe joint compound that resists the

action of L P gas on the male (outstde) lhreads only

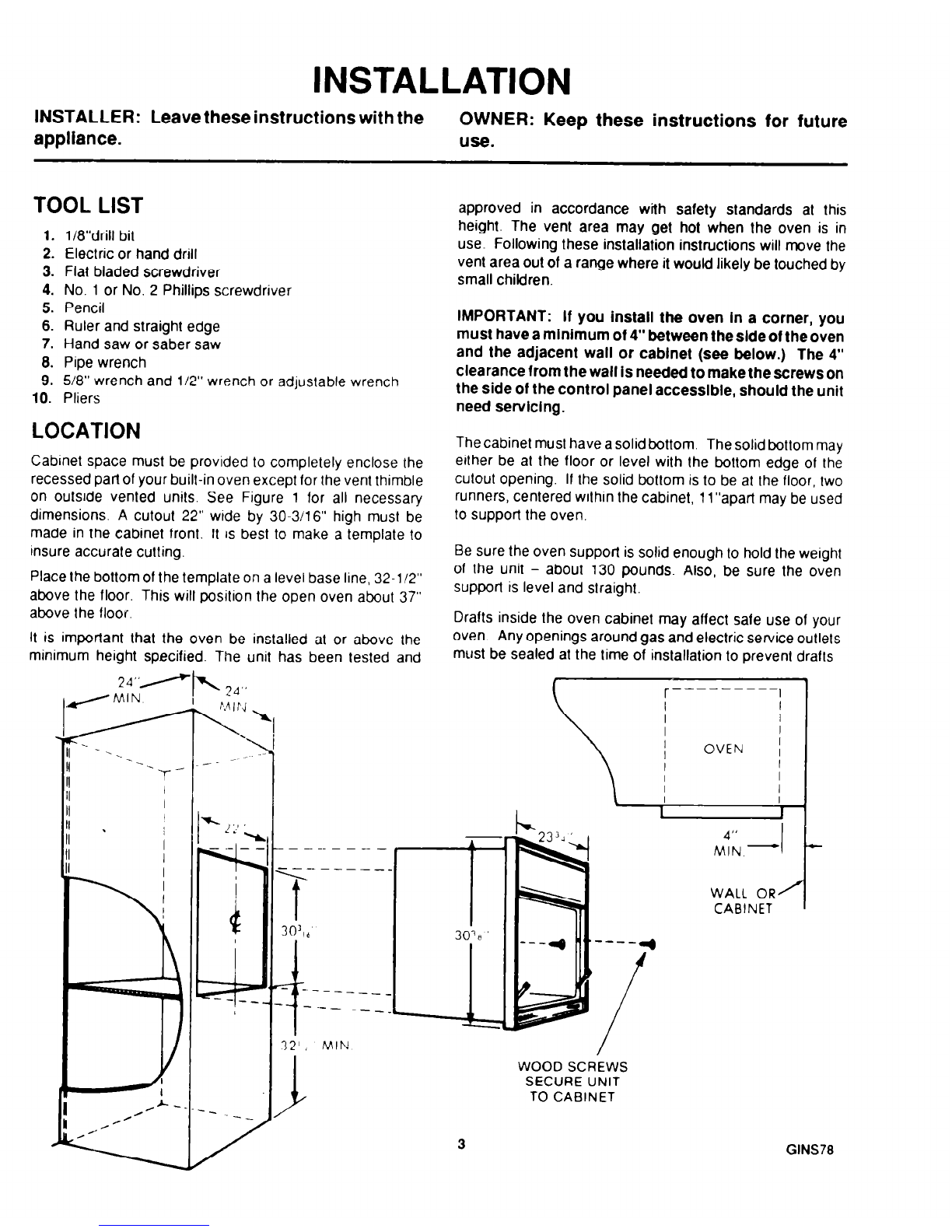

Use 1‘2”gas inlet pope The hole for the gas inlet pipe should

be g-114” to the left of the center line of the cabinet (see

Figure 4) and 23” behlnd the front surface of the cabinet

Connect a 1 2” coupling to the Inlet pipe The top of the

coupling should be about 2-1’2” above the bottom edge of

the cutout opening (see Figure 4) Before you put the oven

into the cabinet opening, connect the 112” reducer shut-off

Jalve to the coupling (see point A In Figure 4) This valve IS

supplied wllh the oven and IS wire-tied to back of unit

Put the oven lnlo lhe cabinet NOTE The oven/brollerdoor

may be removed before Inserting the oven Into the cabinet to

lessen the weight See the inslructlons tn the Cleaning and

Care section of the Owners Manual for removing Ihe door

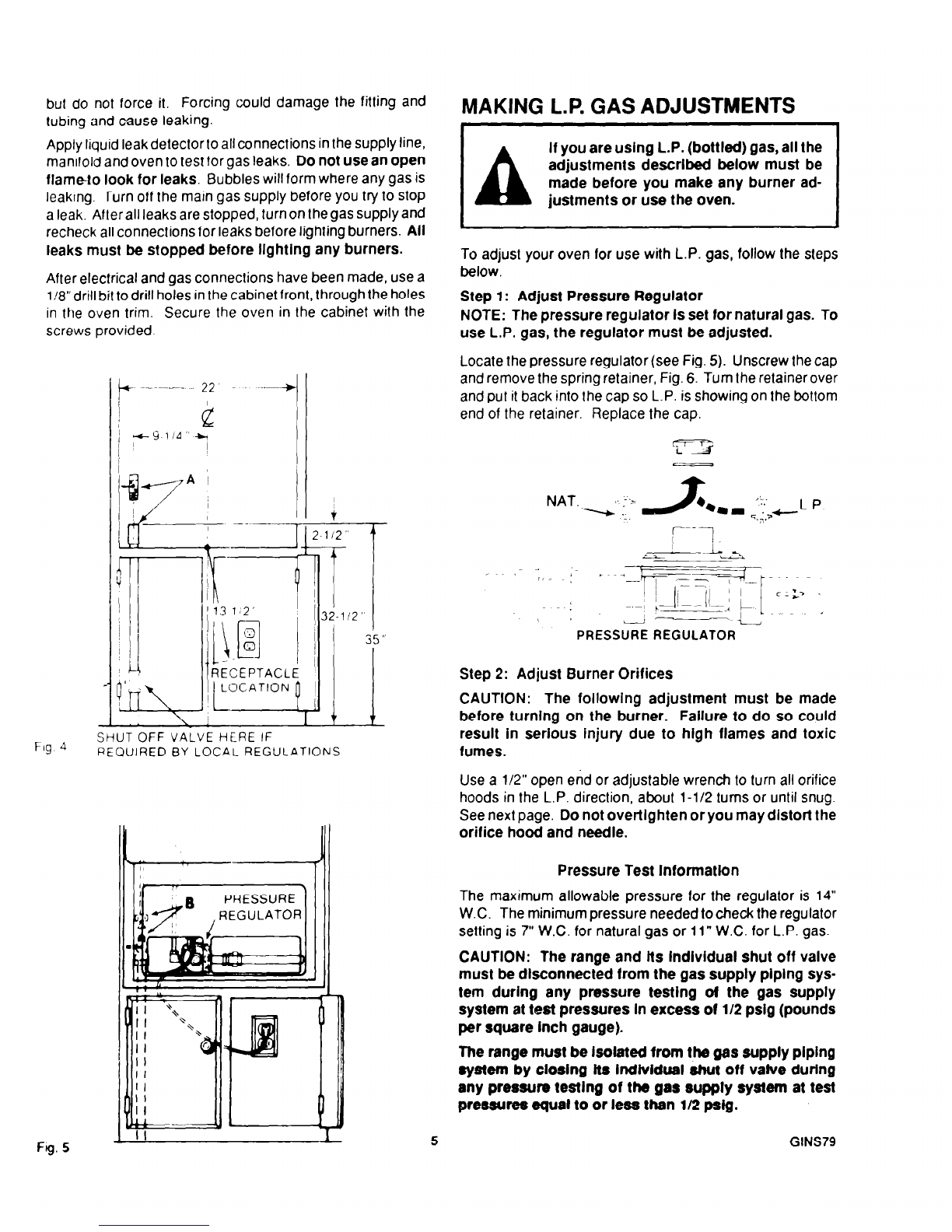

When the oven

IS

In place remove the hookup and adjusl-

ment access covers at the lower oven back (Figure 5)

Reach lhrough the access opening and connect the oven

tubing to the reducer shut off valve (see point B in Figure 5)

Use a 518” wrench to turn the ftttlng Tighten the fitting snugly

4 GINS532