PAGE 2 of 2

Before you begin...

4Ensure that you have sufficient space to work and allow at

least ONE HOUR for assembly, particularly if you have never

built a unit before. We recommend two-person assembly.

4Always use a rubber mallet for assembly and NEVER

a metal hammer. Please note: force is required! The

components are designed to fit tightly together so that they

don’t wobble or break apart, so a light tap will NOT locate the

parts sufficiently.

4We recommend wearing gloves when assembling.

Thank you for purchasing your

ShelvingDirect® shelving

If you have any questions regarding the

assembly or contents of your order, please call

ShelvingDirect® on 0121 508 5877

Monday to Friday 8.30am–5.30pm or email

sales@shelvingdirect.co.uk

ShelvingDirect® is a trading name of Rotadex

Systems Ltd, Systems House, Central Business Park,

Mackadown Lane, Birmingham B33 0JL.

Assembly instructions

STEP 1: Arrange the four uprights [A] so that the

“keyholes” have the larger aperture uppermost:

STEP 2: Begin by attaching the heavy duty plastic feet [B] to the

base of the upright posts.

STEP 3: With one person holding two uprights parallel, join them

by adding a side beam [C] near the top (at the desired level for the

uppermost shelf) by striking its lugs firmly down into the “keyholes”

of the uprights using a rubber mallet. Force is required. NOTE:

the lugs do not need to go completely to the bottom of the

keyholes. Pinch the side beam and upright together using thumb

and forefinger directly between the lugs to ensure they are located

before hammering.

STEP 4: Add a second side beam [C] near the bottom and at the

desired level for the lower shelf level.

STEP 5: Add the remaining two side beams [C], spacing them as

you require. Using this first sub-assembly as a ‘spacing guide’,

repeat this process with the other two uprights to create another

“ladder”. These form the left and right sides of your shelving unit.

STEP 6: Take a cross beam [D] and join the two “ladders” together

by attaching it near the top, at the same height as the uppermost

side beams. Repeat at the bottom.

STEP 7: Add cross beams [D] to the back of the unit too, and fit all

remaining cross beams ensuring they are located at the same height

as their corresponding side beams [C].

STEP 8: If you have purchased an 1800mm+ wide unit, tap in the

centre support beams [E].You may need to push the cross beams

[D] towards one-another to do this.

STEP 9: Lastly, add the shelf levels [F].You will find it easier to

swivel the shelves in at an angle. The shelves are slightly smaller

than the space they fill, to aid assembly.

[C]

[D]

[E]

[F]

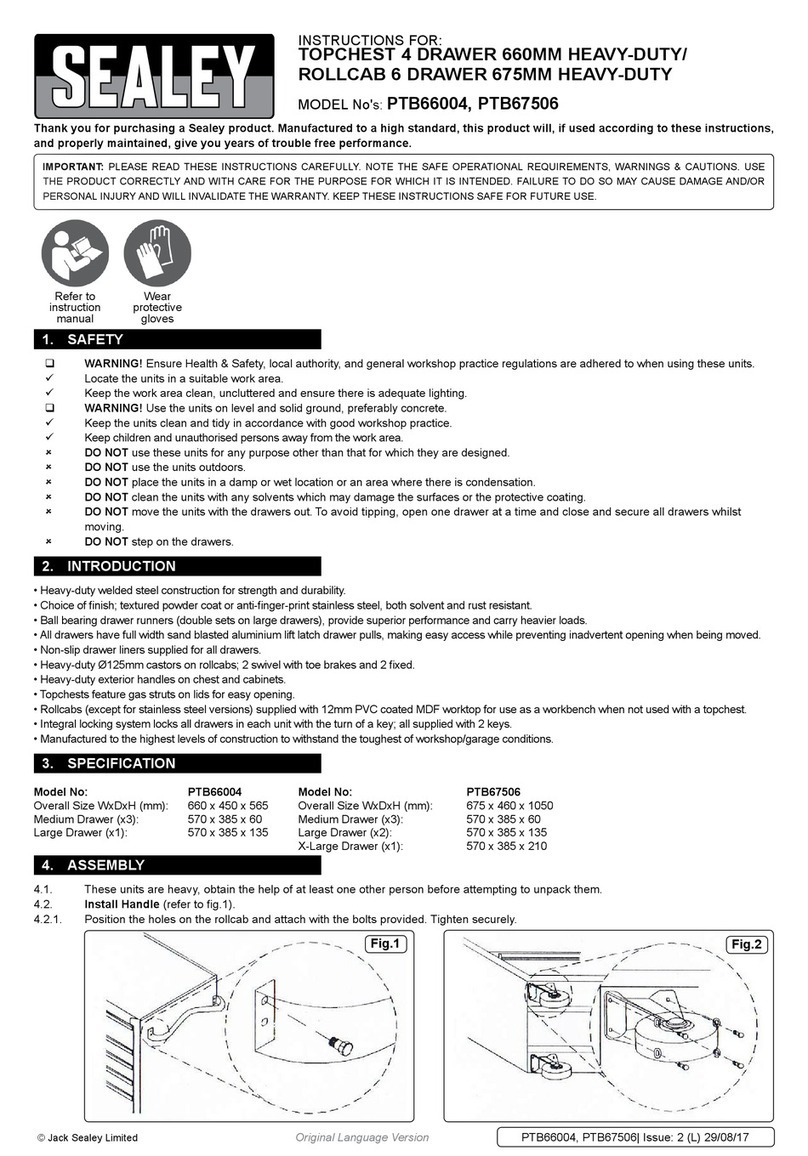

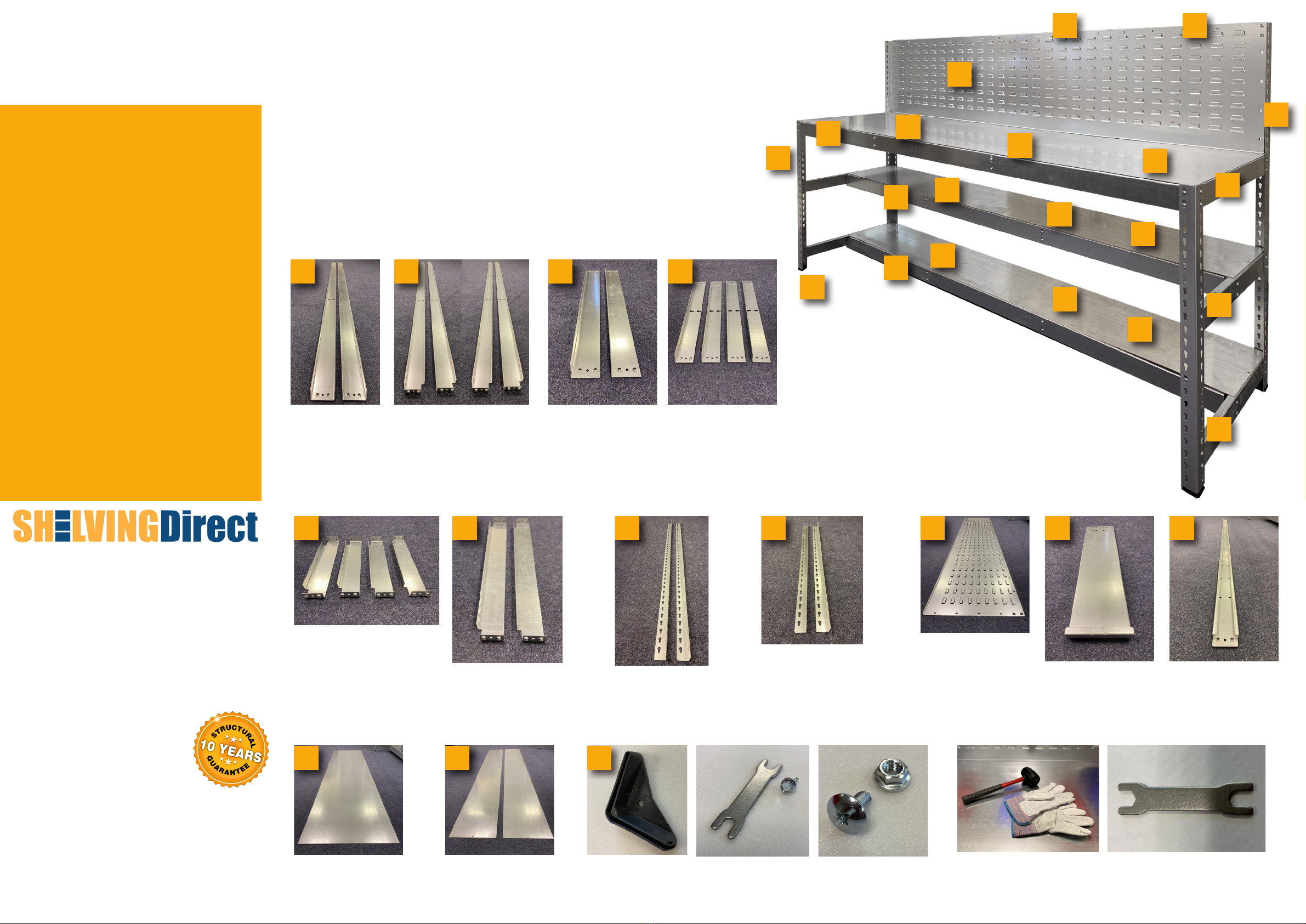

GALV WORKBENCH + LOUVRE PANEL

ASSEMBLY INSTRUCTIONS

Arrange the four uprights [G, H] so that the “keyholes’ have the larger

aperture uppermost. Add the four plastic feet [N] to bottom of each upright.

G H N

“Keyholes”

MUST

have the

larger aperture

uppermost!

With one person holding one tall upright

[G] and one short upright [H] parallel,

join them by adding side beams [C, D]

as pictured. Use the rubber mallet to

strike the sidebeams’ lugs rmly down

in the the “keyholes”.

FORCE IS REQUIRED!

Pinch the side beam and upright

together using thumb and forenger

to ensure lugs and holes are located

before hammering. IMPORTANT:

ensure [D] side beams are used for

the two lower beams, and side beam

[C] as the upper beam. Repeat this

process to create the other end of your

workbench.

G

H

C

D

D

Assemble both ends of the workbench

Before you begin...

4Ensure that you have sufficient space to work and allow at

least ONE HOUR for assembly, particularly if you have never

built a unit before. We recommend two-person assembly.

4Always use a rubber mallet for assembly and NEVER

a metal hammer. Please note: force is required! The

components are designed to fit tightly together so that they

don’t wobble or break apart, so a light tap will NOT locate the

parts sufficiently.

4We recommend wearing gloves when assembling.

Thank you for purchasing your

ShelvingDirect® shelving

If you have any questions regarding the

assembly or contents of your order, please call

ShelvingDirect® on 0121 508 5877

Monday to Friday 8.30am–5.30pm or email

sales@shelvingdirect.co.uk

ShelvingDirect® is a trading name of Rotadex

Systems Ltd, Systems House, Central Business Park,

Mackadown Lane, Birmingham B33 0JL.

Assembly instructions

STEP 1: Arrange the four uprights [A] so that the

“keyholes” have the larger aperture uppermost:

STEP 2: Begin by attaching the heavy duty plastic feet [B] to the

base of the upright posts.

STEP 3: With one person holding two uprights parallel, join them

by adding a side beam [C] near the top (at the desired level for the

uppermost shelf) by striking its lugs firmly down into the “keyholes”

of the uprights using a rubber mallet. Force is required. NOTE:

the lugs do not need to go completely to the bottom of the

keyholes. Pinch the side beam and upright together using thumb

and forefinger directly between the lugs to ensure they are located

before hammering.

STEP 4: Add a second side beam [C] near the bottom and at the

desired level for the lower shelf level.

STEP 5: Add the remaining two side beams [C], spacing them as

you require. Using this first sub-assembly as a ‘spacing guide’,

repeat this process with the other two uprights to create another

“ladder”. These form the left and right sides of your shelving unit.

STEP 6: Take a cross beam [D] and join the two “ladders” together

by attaching it near the top, at the same height as the uppermost

side beams. Repeat at the bottom.

STEP 7: Add cross beams [D] to the back of the unit too, and fit all

remaining cross beams ensuring they are located at the same height

as their corresponding side beams [C].

STEP 8: If you have purchased an 1800mm+ wide unit, tap in the

centre support beams [E].You may need to push the cross beams

[D] towards one-another to do this.

STEP 9: Lastly, add the shelf levels [F].You will find it easier to

swivel the shelves in at an angle. The shelves are slightly smaller

than the space they fill, to aid assembly.

[C]

[D]

[E]

[F]

GALV WORKBENCH + LOUVRE PANEL

BB

BB

B

B

Before you begin...

4Ensure that you have sufficient space to work and allow at

least ONE HOUR for assembly, particularly if you have never

built a unit before. We recommend two-person assembly.

4Always use a rubber mallet for assembly and NEVER

a metal hammer. Please note: force is required! The

components are designed to fit tightly together so that they

don’t wobble or break apart, so a light tap will NOT locate the

parts sufficiently.

4We recommend wearing gloves when assembling.

Thank you for purchasing your

ShelvingDirect® shelving

If you have any questions regarding the

assembly or contents of your order, please call

ShelvingDirect® on 0121 508 5877

Monday to Friday 8.30am–5.30pm or email

sales@shelvingdirect.co.uk

ShelvingDirect® is a trading name of Rotadex

Systems Ltd, Systems House, Central Business Park,

Mackadown Lane, Birmingham B33 0JL.

Assembly instructions

STEP 1: Arrange the four uprights [A] so that the

“keyholes” have the larger aperture uppermost:

STEP 2: Begin by attaching the heavy duty plastic feet [B] to the

base of the upright posts.

STEP 3: With one person holding two uprights parallel, join them

by adding a side beam [C] near the top (at the desired level for the

uppermost shelf) by striking its lugs firmly down into the “keyholes”

of the uprights using a rubber mallet. Force is required. NOTE:

the lugs do not need to go completely to the bottom of the

keyholes. Pinch the side beam and upright together using thumb

and forefinger directly between the lugs to ensure they are located

before hammering.

STEP 4: Add a second side beam [C] near the bottom and at the

desired level for the lower shelf level.

STEP 5: Add the remaining two side beams [C], spacing them as

you require. Using this first sub-assembly as a ‘spacing guide’,

repeat this process with the other two uprights to create another

“ladder”. These form the left and right sides of your shelving unit.

STEP 6: Take a cross beam [D] and join the two “ladders” together

by attaching it near the top, at the same height as the uppermost

side beams. Repeat at the bottom.

STEP 7: Add cross beams [D] to the back of the unit too, and fit all

remaining cross beams ensuring they are located at the same height

as their corresponding side beams [C].

STEP 8: If you have purchased an 1800mm+ wide unit, tap in the

centre support beams [E].You may need to push the cross beams

[D] towards one-another to do this.

STEP 9: Lastly, add the shelf levels [F].You will find it easier to

swivel the shelves in at an angle. The shelves are slightly smaller

than the space they fill, to aid assembly.

[C]

[D]

[E]

[F]

GALV WORKBENCH + LOUVRE PANEL

Your workbench

should now

look like the one

pictured here

Join the end pieces created in Step 2 together

using the four 2400mm width beams [B], as

pictured right. Ensure that the keyholes in the

width beams are the correct way up.

Starting at the

bottom, connect

the end pieces

with the width

beams

Add the remaining two 2400mm upper width beams [A] to the unit, then

link all width beams using the four 310mm shelf supports [E] and the two 600mm

shelf supports [F], as pictured. Hammer these shelf supports down in the “keyholes”

on the cross beams to provide a tight grip. IMPORTANT: You may need to apply

pressure to the cross beams in order to bring them closer together to enable the

shelf supports to be inserted. This helps give the workbench overall stability.

Place all three steel shelves onto the unit [L] and

[M] and secure by xing the self tapping screws

into the holes in the ends of the shelves. Tighten

with spanner provided (or a socket, if you have

one). IMPORTANT: There are holes on the front

edge of the upper shelf which are part of the

manufacturing process, and do not need to have

screws inserted into them.

A

A

E

F

E

M

You are now ready to add the louvre

panel to your workbench. Begin by

adding the nal cross beam [K] to the

top “keyholes” of the rear uprights

(picture right and below).

K

K

Next, add the louvre panel to the rear of the

workbench, ensuring it is the correct way up

(as picture). Use the supplied bolts and nuts to

x the louvre panel to the rear uprights and cross

beam through the holes provided.

I

Finally, add the upright louvre beam [J] to the rear centre point of the [K] beam

using two bolts with serated nuts in the upper two holes.

J

K

ABOVE: The upright

louvre beam should hook

under the lower rear

cross beam.

ABOVE: The top of the upright

louvre beam [J] should slot between

the [K] beam and the louvre panel

[I], and is held in place by two bolts

and nuts that should pass through

all three components.

J

K

I

Optional Pick Bins

If you have purchased pick bins to use with your unit,

ensure that they are correctly tted to the louvre

panel, as pictured. For accessories or help, please

see www.shelvingdirect.co.uk or call us.

STEP 2

STEP 1

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

The uppermost

side beam does

NOT have a

“keyhole” at its

centre F

L

Tel: 0121 508 5877