IM No.: IM/V/0015, Rev. 7

Date: 14.10.2019

Page 3 of 6

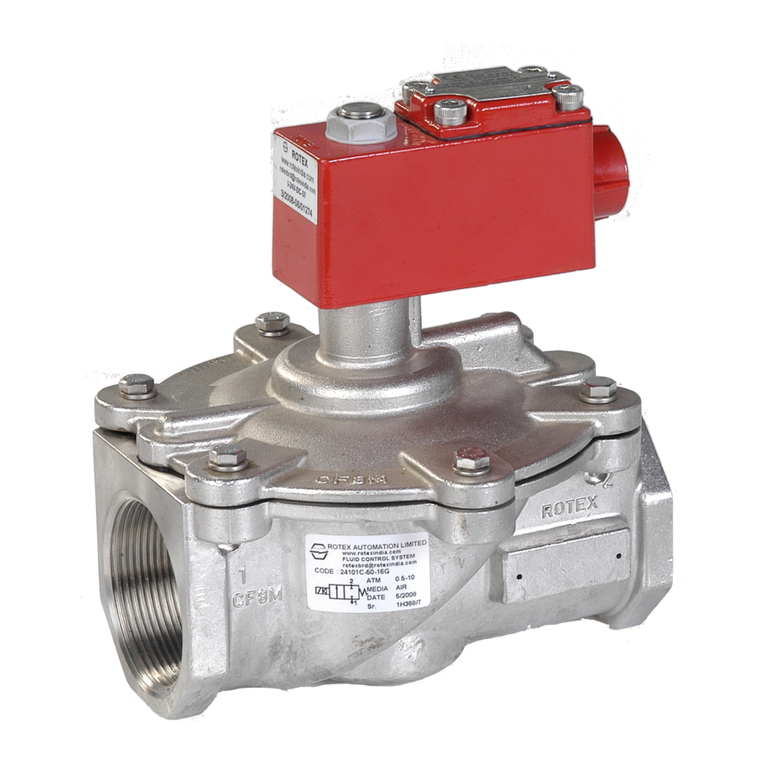

b) SOLENOID MARKING

(1)

ROTEX

VADODARA –390010,

INDIA

Logo + Name of the Manufacturer

Solenoid Type

Solenoid Size III

Solenoid Voltage

Solenoid Insulation Class H

Work order No. Manufacturing Month / Year

(2) (3)

c) PORT IDENTIFICATION

A solenoid Valve with NPT (F) threading is normally marked “N” near the port and with Metric threads are

marked “M”. For ports with BSP threads, there is no marking.

d) Voltage, current & other details are additionally laser marked on Solenoid.

NOTE: The product without marking is out of warranty and risk

B) MOUNTING/INSTALLATION PROCEDURE:

1. ENSURE THAT:

a) While storing, keep the valve in cool, dry, dust free area.

b) On receipt of the valve, in case if the same is to be removed from the sealed plastic bag for

inspection/testing, put them back with dust plugs on its ports and sealing the plastic bag as soon as the

inspection/testing is over.

c) The valve should be removed from its card board and/or plastic bag just before the installation.

d) Flush lines before installing the valve.

e) To avoid pressure, drop and to achieve optimum parameters, Pipe / Tube / Fitting from the source of

pressure to the valve and to the connected equipment should have ID which is NW (Orifice) of the valve.

f) To avoid pressure, drop, if more than one valve is being operated simultaneously from a common header,

then minimum ID of the header can be calculated as under.

ID Header = (NW2n)

n = Number of Valves operating at a time and which are connected to a common header,

NW = Orifice of the Valve.

g) Incorporate filter in the line to avoid hard particles entering the valve.

h) The valve should be installed for the media for which it is intended for. This is to avoid the

malfunction of seals and the valve. In case if you intend to use valve for media other than the one

specified on that valve, check compatibility of media to Body Seal material and grease. Consult

ROTEX in case if any doubt.

i) Do not try to drill any additional holes or machine, modify any of the valve components.

j) In case if the valve is used for dangerous fluid gas/liquid then, the user is hereby advised to maintain

during operation and maintenance of the valve below LEL or above UEL to avoid explosion due to internal

spark as the valves have not been assessed for the same.

k) Inlet pressure does not exceed rated pressure.

l) Hemp-Filaments, ‟Jute‟ or even Teflon-Ribbons are normally not required, as the port connections of

ROTEX Valve is accurately machined.

m) To avoid over lap of the Teflon ribbon or cuts generated while tightening, getting carried away into the

valve. Do not cover first two thread pitches with Teflon tape or sealant.

n) For Solenoid Valve to be installed in European Union, check the applicability for ATEX, PED. Refer

separate Instruction Manual for ATEX approved Solenoid Valve.

2. Provide Dust Cap on the exhaust port or ensure that the valve is mounted such a way that dust particles / rain water

/ process fluid do not enter the valve through exhaust port of the valve. You can connect bend pipe of ID > NW of

the valve so that the exhaust port is not directly (straight) open into the atmosphere.

3. The process fluid etc.: do not fall on the valve body.

4. In case if the surrounding atmosphere has traces or some other substance other than Air, check its compatibility

with the Body material of the valve, Solenoid enclosure & other exposed parts.

5. In case if the valve is installed in potentially Hazardous area, check for the temperature class of the Solenoid to

avoid explosion due to heated Solenoid / other components.

6. Provide fuse of proper rating to avoid excess current passing through the Solenoid and thereby avoiding over

heating.

7. It is not likely however; the user is advised to protect the valve against lightening as the same is not assessed.

8. Check internal components (wetted) parts for its compatibility with fluid passing through the valve.

9. It is recommended to replace all the Rubber Parts including Plunger Assembly in case if the valve is to be

installed and put in service after 2 years from the date of manufacture.