Operating instruction piston accumulator UAK - English

1

0 Contents

0.1 Table of Contents

0

Contents____________________________________________________________________ 1

0.1

Table of Contents_____________________________________________________________ 1

0.2

Table of figures_______________________________________________________________ 1

1

Designated application_________________________________________________________ 2

1.1

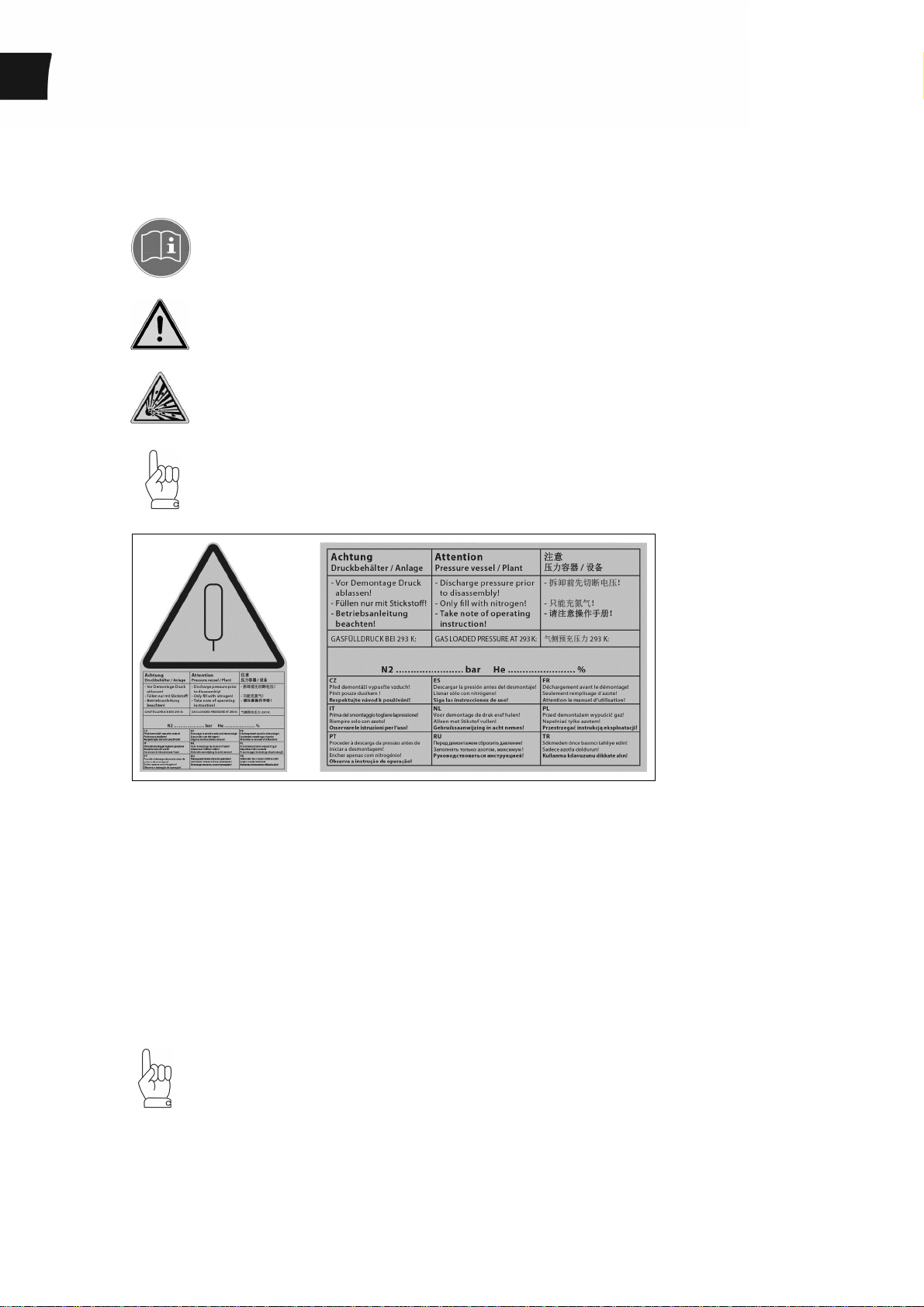

Overview of standard Roth pressure equipment _____________________________________ 2

1.2

Notes on designated application _________________________________________________ 3

2

Function ____________________________________________________________________ 4

2.1

General functional description ___________________________________________________ 4

2.2

Filling and testing the pressure equipment _________________________________________ 4

2.2.1

Isochore behavior of N2________________________________________________________ 5

3

Safety______________________________________________________________________ 6

3.1

Notes / Explanations __________________________________________________________ 6

3.2

Identification / Nameplate_______________________________________________________ 6

3.3

Safety systems_______________________________________________________________ 6

3.4

Safety precautions ____________________________________________________________ 6

3.5

Responsibilities of the operator __________________________________________________ 7

4

Dangers ____________________________________________________________________ 8

4.1

General hazard notes__________________________________________________________ 8

4.2

Installation of spare and wearing parts ____________________________________________ 8

4.3

Cleaning, maintenance and repair work ___________________________________________ 8

5

Installation __________________________________________________________________ 8

5.1

Scope of delivery _____________________________________________________________ 8

5.2

Transport and packaging _______________________________________________________ 9

5.3

Storage_____________________________________________________________________ 9

5.4

Assembly / Commissioning ____________________________________________________ 10

6

Maintenance________________________________________________________________ 11

6.1

General maintenance notes____________________________________________________ 11

6.2

Periods of repeated inspection__________________________________________________ 11

7

Disturbance, causes, troubleshooting (qualified staff only) ____________________________ 12

8

Emergencies _______________________________________________________________ 12

9

Dissembling / disposal ________________________________________________________ 12

Notes __________________________________________________________________________ 13

0.2 Table of figures

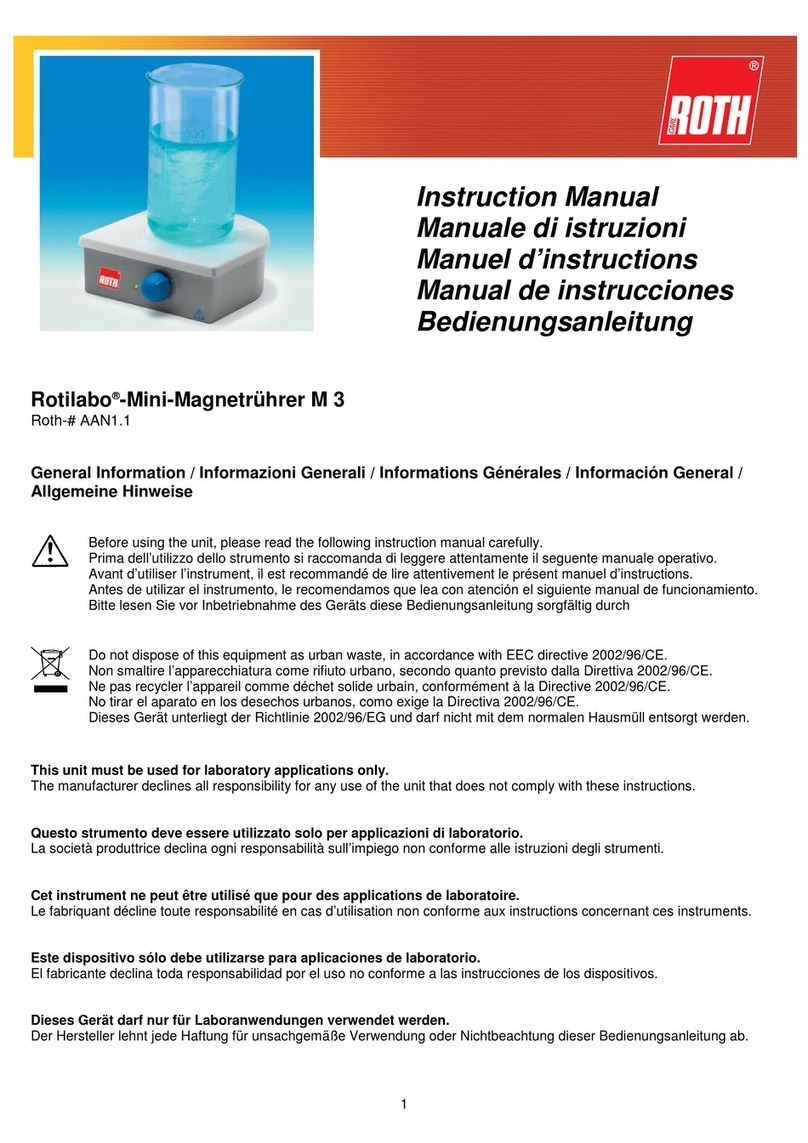

Figure 1-1 Overview of standard Roth pressure equipment _____________________________ 2

Figure 2-1 Isochore behavior of N2 ________________________________________________ 5