Section 1 Introduction 1-2 EM69P Manual

www.rottlermfg.com

Description

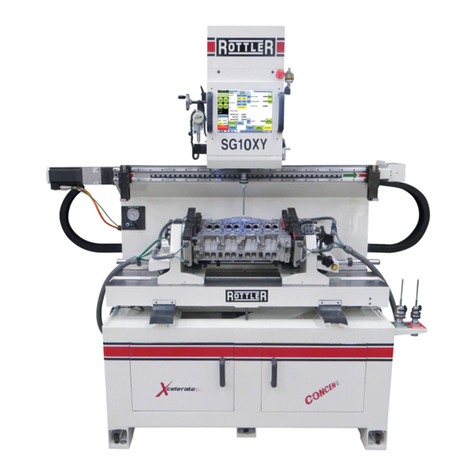

The Rottler EM69P is a 5-axis CNC machine designed and developed specially for porting cylinder

heads. The design of the machine allows the center of the “ball shaped” cutting tool to rotate about its

own center on the 5th axis.

This unique design has many benefits to a performance engine builder of which the most important are

ease of programming and the fastest and most accurate method to port cylinder heads.

Disclaimer

The EM69P Manual (henceforth to be referred to as the “Manual”) is proprietary to Rottler Manufacturing

LLC. (“Rottler Manufacturing”) and no ownership rights are hereby transferred. No part of the Manual

shall be used, reproduced, translated, converted, adapted, stored in a retrieval system, communicated or

transmitted by any means, for any commercial purpose, including without limitation, sale, resale, license,

rental or lease, without the prior express written consent of Rottler Manufacturing.

Rottler Manufacturing does not make any representations, warranties or guarantees, express or implied,

as to the accuracy or completeness of the Manual. Users must be aware that updates and amendments

will be made from time to time to the Manual. It is the user’s responsibility to determine whether there

have been any such updates or amendments. Neither Rottler Manufacturing nor any of its directors,

officers, employees or agents shall not be liable in any manner whatsoever to any person for any loss,

damage, injury, liability, cost or expense of any nature, including without limitation incidental, special,

direct or consequential damages arising out of or in connection with the use of the Manual.

Rottler Manufacturing and its employees or representatives are not responsible for any information

regarding final specifications of any workpiece that is created as a final product when using Rottler

equipment. It is the responsibility of the end user of Rottler equipment to determine the final dimensions

and finishes of the workpiece that they are working on. Any information regarding final dimensions and

finishes that appears in any Rottler literature or that is expressed by anyone representing Rottler is to

be regarded as general information to help with the demonstration of or for operator training of Rottler

equipment.

Limited Warranty

Rottler Manufacturing Company Model EM69P parts and equipment is warranted as to materials and

workmanship. This limited warranty remains in effect for one year from the date of installation or two

years from the date of the original shipment from Rottler or whichever date occurs first. This only applies

is the machine is owned and operated by the original purchaser and is operated and maintained as per

the instructions in the manual. A machine is warranted only if the Installation Report has been properly

executed by a certified installation person and received by Rottler at the time of actual installation.

The products are warranted upon delivery to conform to their published specifications and to be free from

defects in material and workmanship under normal use for a period of one year from shipment. Should a

product not be as warranted, Rottler sole obligation shall be, at its option, to repair, correct or replace the