Section 1 Introduction HP7A Manual

www.rottlermfg.com

1-2

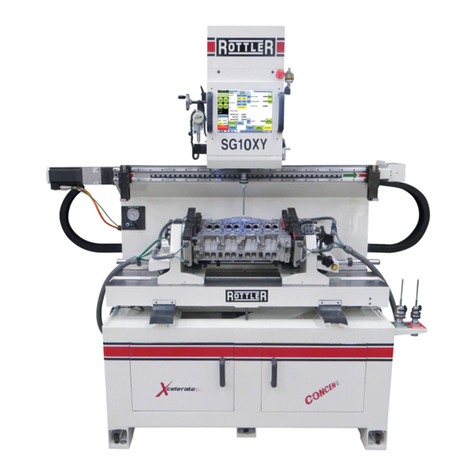

Description

The model HP7A Honing Machine is a wet, complete cylinder block and general purpose-honing

machine. A totally enclosed AC motor driving a belt and gear reduction drive mounted within a rocker arm

arrangement supplies Hone rotating power. The honing head is driven through a universal joint.

An air cylinder with a hydraulic check system provides stroking power. Stroking may also be manually

operated.

A Windows based touch screen panel provides easy and convenient control of the HP7A. Block programs

can be created and stored to memory for later recall, providing a quick set up for honing common blocks.

All preferences such as dwell setting, cross hatch angle, and honing loads are automatically set up when

a block program is selected at time of machine set-up.

The support carriage is mounted on linear rails to provide simple and easy hole-to-hole setup.

Convenient devices are provided to properly control honing operations and provide easy handling.

A ‘V’ xture is provided, which efciently holds V-6/V-8, and in-line blocks for honing. Optional clamps are

available to clamp most any kind of in-line block or similar work piece.

Fixtures are available for doing large industrial engine sleeves.

A splash tank is located within the main frame and a coolant pump tank is located under the machine. A

button is provided on the control panel to operate the coolant system.

Disclaimer

The HP7A Manual (henceforth to be referred to as the “Manual”) is proprietary to Rottler Manufacturing

LLC. (“Rottler Manufacturing”) and no ownership rights are hereby transferred. No part of the Manual

shall be used, reproduced, translated, converted, adapted, stored in a retrieval system, communicated or

transmitted by any means, for any commercial purpose, including without limitation, sale, resale, license,

rental or lease, without the prior express written consent of Rottler Manufacturing.

Rottler Manufacturing does not make any representations, warranties or guarantees, express or implied,

as to the accuracy or completeness of the Manual. Users must be aware that updates and amendments

will be made from time to time to the Manual. It is the user’s responsibility to determine whether there

have been any such updates or amendments. Neither Rottler Manufacturing nor any of its directors,

ofcers, employees or agents shall not be liable in any manner whatsoever to any person for any loss,

damage, injury, liability, cost or expense of any nature, including without limitation incidental, special,

direct or consequential damages arising out of or in connection with the use of the Manual.

Limited Warranty

Rottler Manufacturing Company Model HP7A parts and equipment is warranted as to materials and

workmanship. This limited warranty remains in effect for one year from the date of delivery, provided the

machine is owned and operated by the original purchaser and is operated and maintained as per the

instructions in the manual.

Tools proven to be defective within the warranty period will be repaired or replaced at the factory’s option.

The products are warranted upon delivery to conform to their published specications and to be free from

defects in material and workmanship under normal use for a period of one year from shipment. Should a

product not be as warranted, Rottler sole obligation shall be, at its option, to repair, correct or replace the

product or to refund the amounts paid for the Product upon its return to a location designated by Rottler.