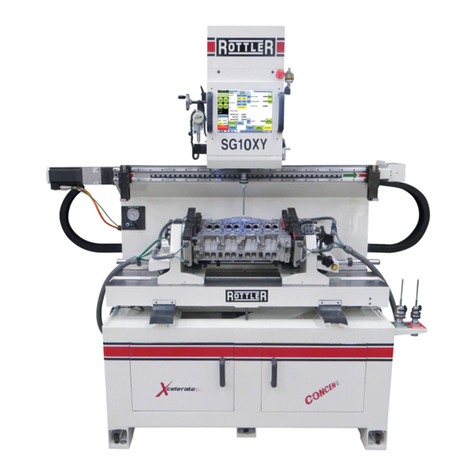

CHAPTER 1 INTRODUCTION / SAFETY / INSTALLATION:2-1

Introduction:................................................................................................................................................2-1

Limited Warranty:.......................................................................................................................................2-1

Safety Information:.....................................................................................................................................2-2

Electrical Power:.........................................................................................................................................2-2

Machine Operator:......................................................................................................................................2-2

Eye Safety:.................................................................................................................................................2-2

Work Area: .................................................................................................................................................2-2

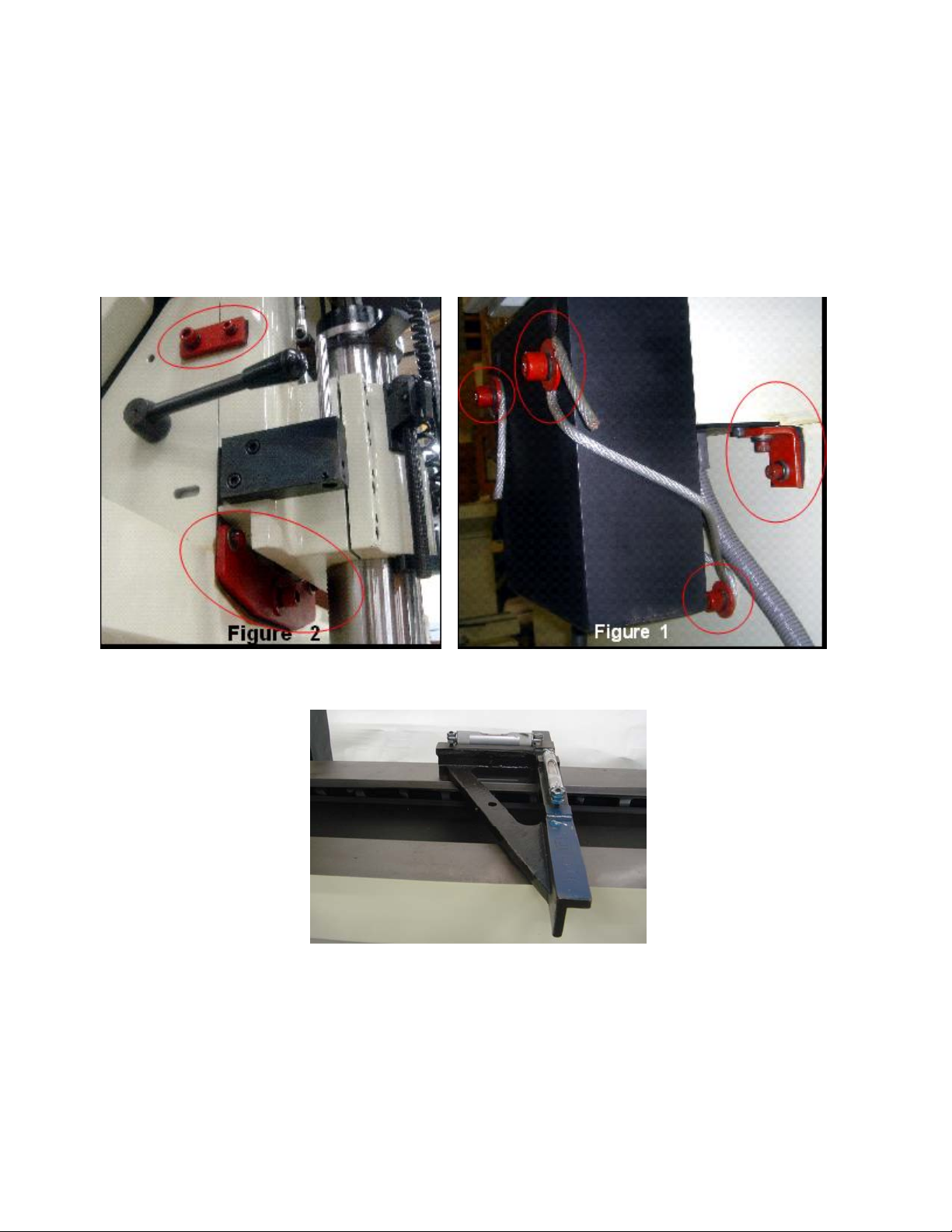

Guards:.......................................................................................................................................................2-2

Overreach:..................................................................................................................................................2-2

Hand Safety:...............................................................................................................................................2-2

Machine Capacity:......................................................................................................................................2-3

Avoid Accidental Starting: ..........................................................................................................................2-3

Careless Acts: ............................................................................................................................................2-3

Job Completion: .........................................................................................................................................2-3

Replacement Parts:....................................................................................................................................2-3

Misuse:.......................................................................................................................................................2-3

Emergency Procedure:...............................................................................................................................2-3

Preparation for Placement:.........................................................................................................................2-3

CHAPTER 2 MACHINE INSTALLATION: 3-1

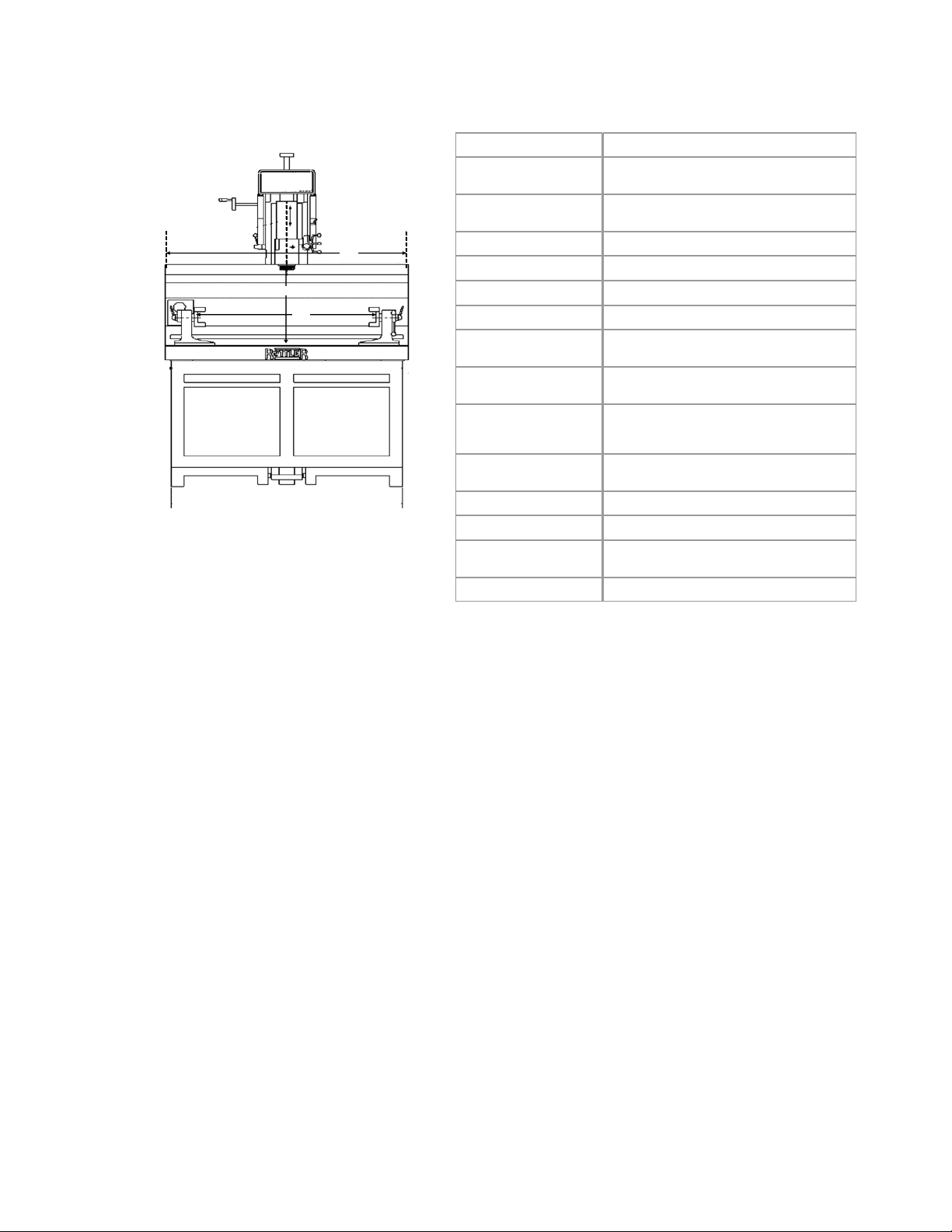

Location:.....................................................................................................................................................3-1

Unpacking: .................................................................................................................................................3-1

Positioning the Machine:............................................................................................................................3-1

Leveling the Machine: ................................................................................................................................3-2

CHAPTER 3 CONTROL DEFINITIONS:4-3

CHAPTER 4 OPERATING INSTRUCTIONS: 5-1

Mounting Cylinder Heads:..........................................................................................................................5-1

Alignment and Setup:.................................................................................................................................5-2

Front to Rear Cylinder Head Alignment:....................................................................................................5-2

Left to Right Alignment:..............................................................................................................................5-2

Selecting the right Pilot:..............................................................................................................................5-3

Three Angle Seat Cutting:..........................................................................................................................5-3

Cut seat only enough to clean up surface..................................................................................................5-3

Changing the Spindle Adapters: ................................................................................................................5-3

Installing the Spherical self Aligning toolholder:.........................................................................................5-3

CHAPTER 5 SPINDLE TO WORK: 6-4

Fine Feed Engagement:.............................................................................................................................6-4

Core Drilling and Reaming Valve Guides:..................................................................................................6-4

Cutting Counter Bores for Seat Rings:.......................................................................................................6-5

Tapping Operations:...................................................................................................................................6-5

CHAPTER 6 MAINTENANCE: 7-1