PAGE

2 / 48

Via Ugo Foscolo, 20

36030 - CALDOGNO - VICENZA - ITALY

Rev.5 - 20/03/09

INDEX

Chapter 1: GENERAL WARNINGS BEFORE INSTALLATION ............................................................. pag. 3

- Description of symbols in the manual................................................................................................... pag. 3

- General instructions on safety ............................................................................................................... pag. 3

- Dangerous situations............................................................................................................................. pag. 3

- Responsibility and warranty................................................................................................................... pag. 3

- Compatibility of the manual with the firmware version of the inverter.................................................. pag. 3

Chapter 2: KEYBOARD OPERATING INSTRUCTIONS ........................................................................ pag. 4

- General description ................................................................................................................................ pag. 4

- Display when starting ............................................................................................................................. pag. 4

- Keys function........................................................................................................................................... pag. 4

- Procedure to modify a parameter .......................................................................................................... pag. 4

Chapter 3: QUICK INSTALLATION IN SCALAR MODE........................................................................ pag. 5-7

- Quick installation aims ........................................................................................................................... pag. 5

- Connection diagrams............................................................................................................................. pag. 5

-Installation ............................................................................................................................................... pag. 6-7

- Procedure to restore default setups ...................................................................................................... pag. 7

Chapter 4: QUICK INSTALLATION IN VECTORIAL MODE .................................................................. pag. 8-9

- Quick installation aims. .......................................................................................................................... pag. 8

- Connection diagrams . ........................................................................................................................... pag. 8

-Installation ............................................................................................................................................... pag. 9

Chapter 5 : TECHNICAL FEATURES ..................................................................................................... pag. 10-13

- Genaral features of the inverter potentialities ....................................................................................... pag. 10-11

- Electric and power characteristics summary tables for the inverter Series 400 ................................. pag. 12-13

- Inverter derating according to PWM frequency ...................................................................................... pag. 13

Chapter6:MECHANICALINSTALLATION ................................................................................................ pag. 14-15

- Drives dimensions and weights ............................................................................................................ pag. 14

- Suggestions for a correct installation.................................................................................................... pag. 15

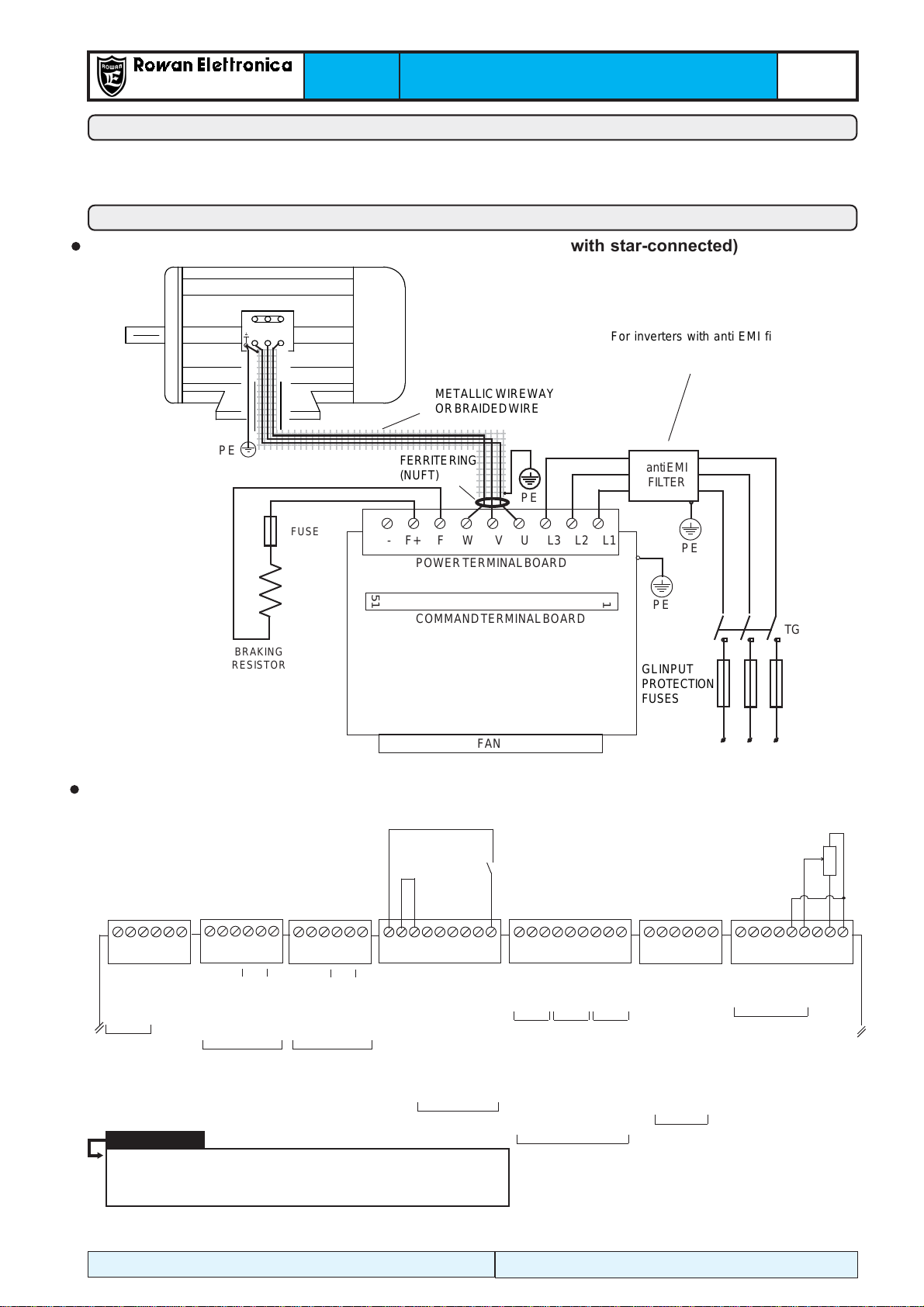

Chapter7:ELECTRICALINSTALLATION................................................................................................. .. pag. 16-19

- General warnings before connection of the threephase power supply ............................................... pag. 16

- Wiring system and electromagnetic compatibility ................................................................................ pag. 16

- Table of threephase anti E.M.I. filters and ferrite toroids for different inverters...................................... pag. 17

- Reducing the harmonic distortion .......................................................................................................... pag. 18

- Table of filters reducing the harmonic distortion for different inverters.................................................. pag. 18

- Reducing the dV/dt .................................................................................................................................. pag. 19

- DV/dt reduction filters table for different inverters ................................................................................... pag. 19

- Electrostatic discharges (ESD)............................................................................................................... pag. 19

Chapter 8: BRAKING RESISTORS ......................................................................................................... pag. 20-21

- Table of braking resistors for Rowan inverters..................................................................................... pag. 20

- Dimensions of Rowan braking resistors .............................................................................................. pag. 21

- Mechanical installation and electrical connection ................................................................................ pag. 21

- Inverter setup for dynamic braking ......................................................................................................... pag. 21

Chapter 9: TERMINAL BOARD DESCRIPTION..................................................................................... pag. 22-27

- Power terminal board description ......................................................................................................... pag. 22

- Standard terminal board for signals description .................................................................................. pag. 22-25

- Optional B404S.A card-edge connectors description........................................................................... pag. 26-27

Chapter 10: COMPLETE PARAMETERS LIST WITH STANDARD SETUPS AND DISPLAYS.......... pag. 28-34

Chapter 11: SUMMARY TABLES FOR I/O RESOURCES PARAMETERS.......................................... pag. 35

Chapter 12: INVERTER FAULTS AND ALARMS ................................................................................. pag. 36

Chapter 13: ROWAN G-SERIES VECTORIAL MOTORS...................................................................... pag. 37-41

- Motors general features ......................................................................................................................... pag. 37

- Motors connection description............................................................................................................... pag. 38-39

- Measures of motors with brake ............................................................................................................. pag. 40

- Brakes electromechanical features table ............................................................................................. pag. 41

- Brake connection .................................................................................................................................... pag. 41

- Fan systems and protection levels table for motors and fans ............................................................. pag. 42

- Motors mechanical limits ....................................................................................................................... pag. 42

- Guide to "Motor/Inverter pairing off" tables............................................................................................. pag. 43

- Motor/Inverter pairing off table (1500 rpm - 380/460Vac)...................................................................... pag. 44

- Motor/Inverter pairing off table (3000 rpm - 380/460Vac)...................................................................... pag. 45

Chapter 14: INFORMATION ON MANUALS .......................................................................................... pag. 46