For more information, see on the net at www.royal-exclusiv.de. Simply enter the part number or name into

the search box or email to: info@royal-exclusiv.de.

All information without guarantee. We try our best, but printing errors reserved.

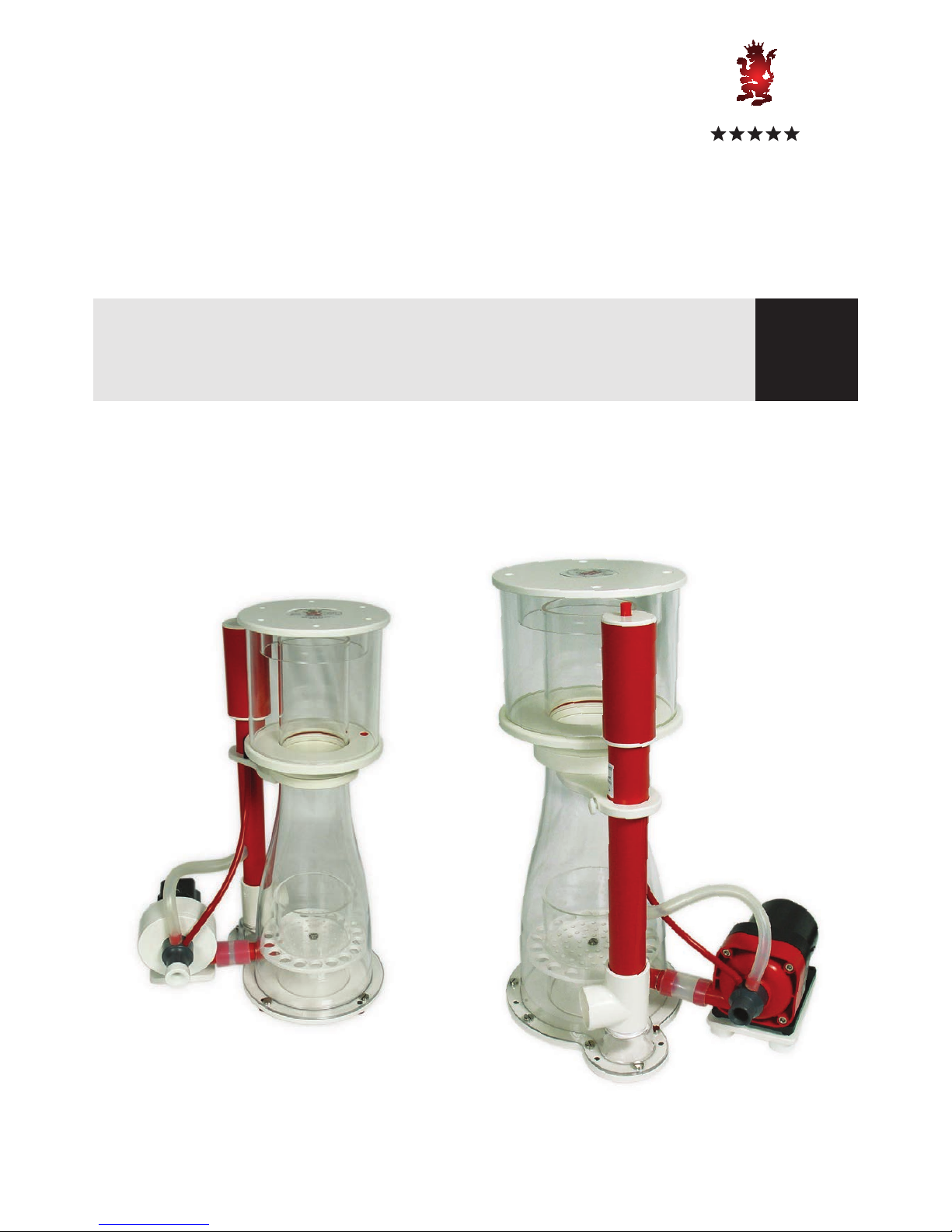

Royal Exclusiv pumps &skimmers

Vorgebirgsstr. 28 // 50389 Wesseling // Germany

Fon +49(0)2236/88055-0 // Fax +49(0)2236/88055-20

info@royal-exclusiv.de // www.royal-exclusiv.de

Since 1986

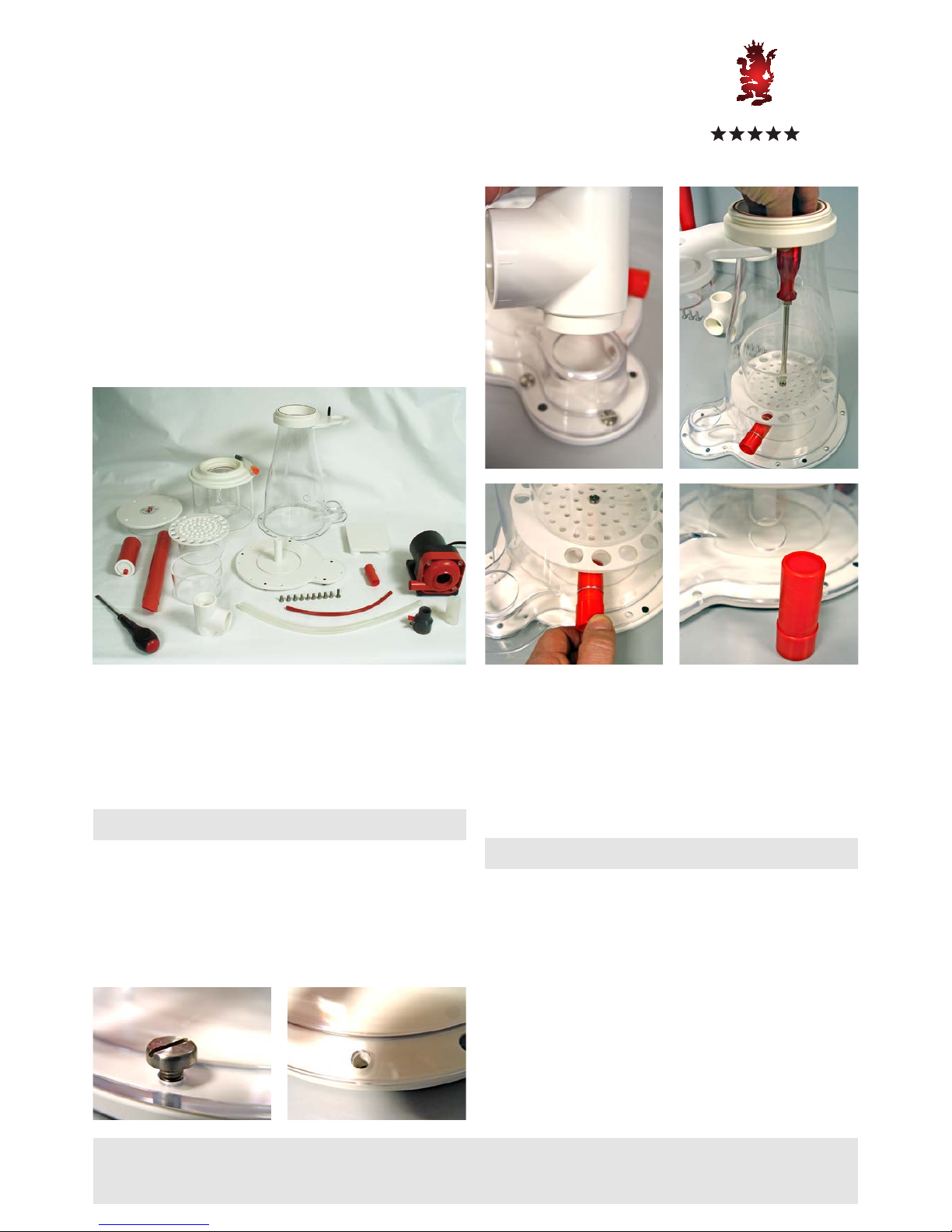

3. Installation of the Red Dragon®3

Mini Speedy with speed regulation

The pump has a DC motor and therefore is equipped with

a driver unit. The Red Dragon®3 Speedy pumps may only

be operated with an ELCB (earth leakage circuit breaker)!!

!! Important !!

Electrical grounding of the wiring of the Red Dragon®3

pumps is absolutely mandatory! Bridge circuits or

grounding over neutral conductor are not permitted and

might cause inductive fault current up to 50 Volt!

Setting-up operation has to take place in the following order:

1. Thoroughlypurgethepump,toremovethedisinfectant.

2. Place the pump below the water level.

(The pump is not regenerative).

3. Insert power plug. Caution: The electrical socket

needs to be grounded.

4. Keep hole of the pump during the test run.

Danger of blowback!

5. The pump starts immedialty (softstart).

6. Usethebuttons(redtriangles)toadjusttherevolutions

per minute.

Note: The pump will start with the display of the

typeofpump(P1-P3).Thentheinitialization(In)takes

place. Afterwards the start message (SP) and the last

selected set wattage will be shown. Through the „Up“ and

„Down“wexedkeysperformancein5Wattincrements.

3.1. Operation of the RD3 pumps with controller

Important Notice:

The imprint on the buttons and LEDs may vary troughout

thetext,thefunctionshoweverremainthesame.

The display is in W (the actual measured effective power

/ energy meter consumption). Note: when you press the

button,thepumpin5(2)Wattincrementscanberegulated.

After a loss of the electrical power supply the pump will

restart in the last valid setting automatically.

Pressing the “plus-key” increases the revolution of the

pump.Thustheowrateandtheenergyconsumptionin-

crease.Pressing the “minus-key” decreases the revolution

ofthepump.Thustheowrateandtheenergyconsump-

tion decrease.

The revolution can be chosen in 5W steps from 15-50W.

Thepumprunsalwaysontheconguredspeed.

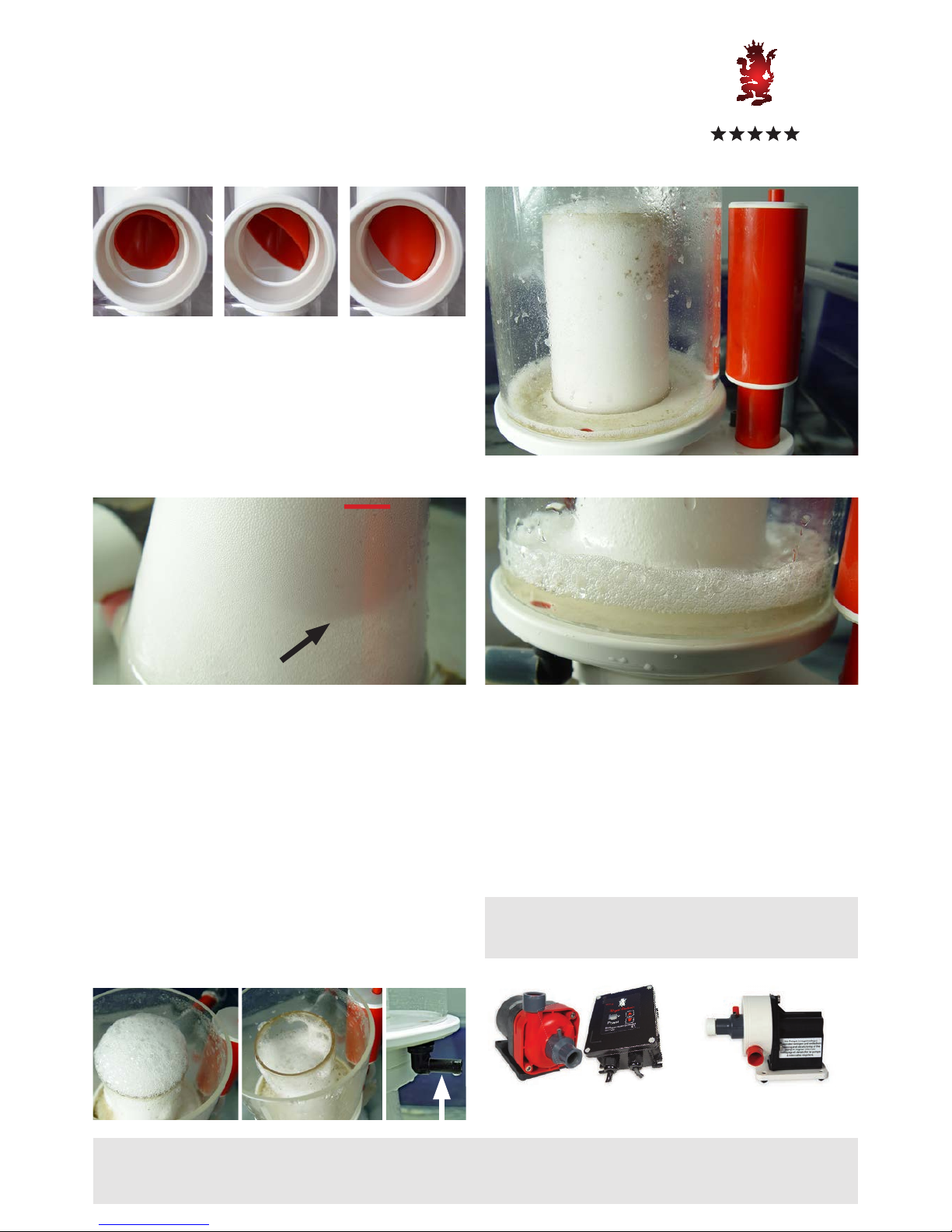

3.2. Maintenance and cleaning

of the Red Dragon 3 Mini Speedy

Disconnect the pump from the power supply prior to each

maintenance work. Red Dragon®supply-andowpumps

areessentiallytobeclassiedaslow-maintenance.Usu-

ally the necessary maintenance work is limited to a check

of the impellor for obstruction. Remove obstacles from the

impellor with a slim and spiky tool.

A decreasing supply rate is often the result of dirt. Pos-

sible calcinations (especially in saltwater applications) has

to be removed with a very soft acid as for instance vinegar.

Avoid applying pressure to the sides of the impellor or the

rotor. The pump can be disassembled nearly completely

for cleaning.

Infreshwater-andsaltwaterapplicationscalcicationonly

appearsinveryhardwaterandafteracompletere-llingof

the pond. After this the largest amount of carbonate will be

omitted within 2-3 days.

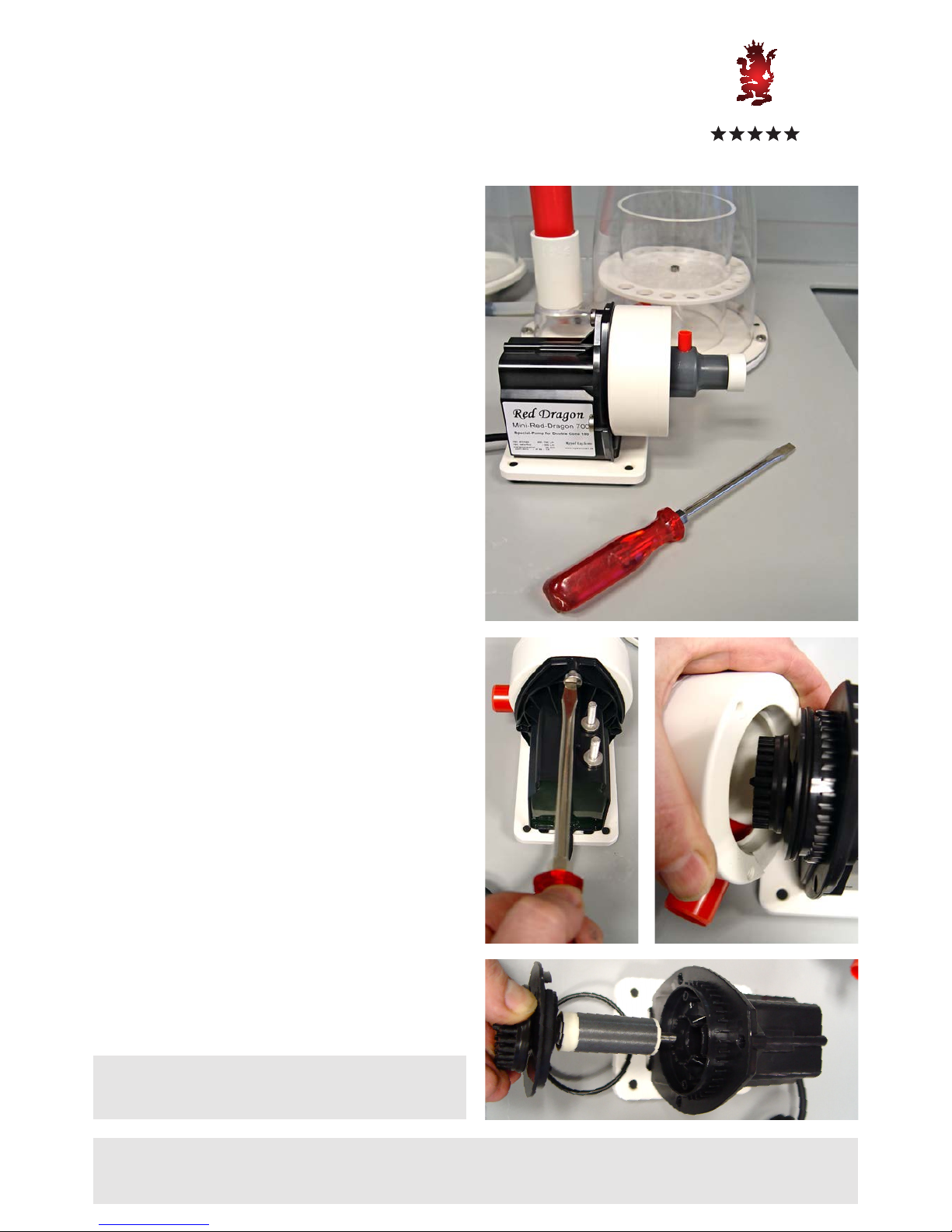

Todismountthepumpsheadfromtheengine,unscrewthe

M5 hexagon socket titanium screws with a matching span-

ner. When this is done the whole pumps head can be re-

moved.Inecessarytheimpellerunitcanberemoved,by

cautiously pulling on the rotor with.

Whenyoupullontherotor,beverycareful,astheimpellor

is held in its position by the magnet. If you release the ro-

torwhiletryingtopullitout,thebearingcangetaserious

damage.

6