Secure the soldering tool.

Use clamping devices to hold the workpiece rmly

in position. This is a safer way to hold the workpiece

than in your hands, and also leaves both hands free

to operate the soldering tool.

Avoid unintentional starting.

When plugging into the socket, ensure that it is

switched off at the mains. Never carry a soldering

tool connected to the mains power supply.

Maintenance and Handling

Regularly inspect the station for physical damage

that may affect safety.

Do not use the station if it:

is visibly damaged-

has ceased to function-

has been stored for a long period under -

unfavourable conditions; has been subject to

heavy stresses during transportation

If suspected to be unsafe for use, the

station must immediately be switched off

and the mains plug must be disconnected

from the supply.

Before switching on, allow the station to attain

ambient room temperature.

When in use, always ensure the station is ●

sufficiently ventilated.

Place the station on a flame-resistant base-pad in ●

such a way that air can circulate freely.

The station must not be exposed to water, dust or ●

direct sunlight.

Avoid subjecting the apparatus to heavy ●

mechanical stress.

The iron attains working temperatures between ●

150°C - 450°C. Contact with any of its metallic parts

may cause serious burns to people or animals.

Before carrying out cleaning or

maintenance on the station, observe

the following Safety Instructions:

This product contains no user

serviceable parts.

Repair must only be carried out by a specialist ●

aware of the associated risks.

Always disconnect from the mains before opening ●

covers or withdrawing parts.

Even after the device has been disconnected ●

from all voltage sources, it is possible that internal

capacitors may still be charged. Unplug the station

and leave for 5 minutes before removing covers.

The DS80 is fitted with a slow-blowing 1 A fuse. ●

This must always be replaced with the same type

and value. Disconnect from the mains supply

before replacing. The fuse-holder is located on the

underside of the station.

Use a dry linen cloth to clean. Moisten very slightly ●

if necessary, ensuring that no moisture penetrates

inside the device. Do not use solvents such as

petrol or kerosene, or abrasive cleaners to clean

the unit.

Disposal

In the event that the DS80 has become

unserviceable it must be disposed of in accordance

with applicable statutory regulations.

Brief Summary of

Instructions for Use

1. Assemble the station and rest, and place the

iron on the rest, then connect the power lead to

the mains.

2. Switch on using “Power” switch.

3. Press “+”/”-“ keys to adjust the set point

temperature or select one of the programmed

temperatures by using the “T1”/”T2”/”T3” keys.

4. Modify a programmed set point temperature by

pressing “+”/”-“ whilst holding the appropriate

“T1”/”T2”/”T3” key.

Instructions for Use

1. Setting up

First set up and connect to a mains socket. Insert the

plug from the soldering iron in the DIN socket located

on the front of the station. The solder sponge must

be laid in the stand and moistened with water.

2. Switching on

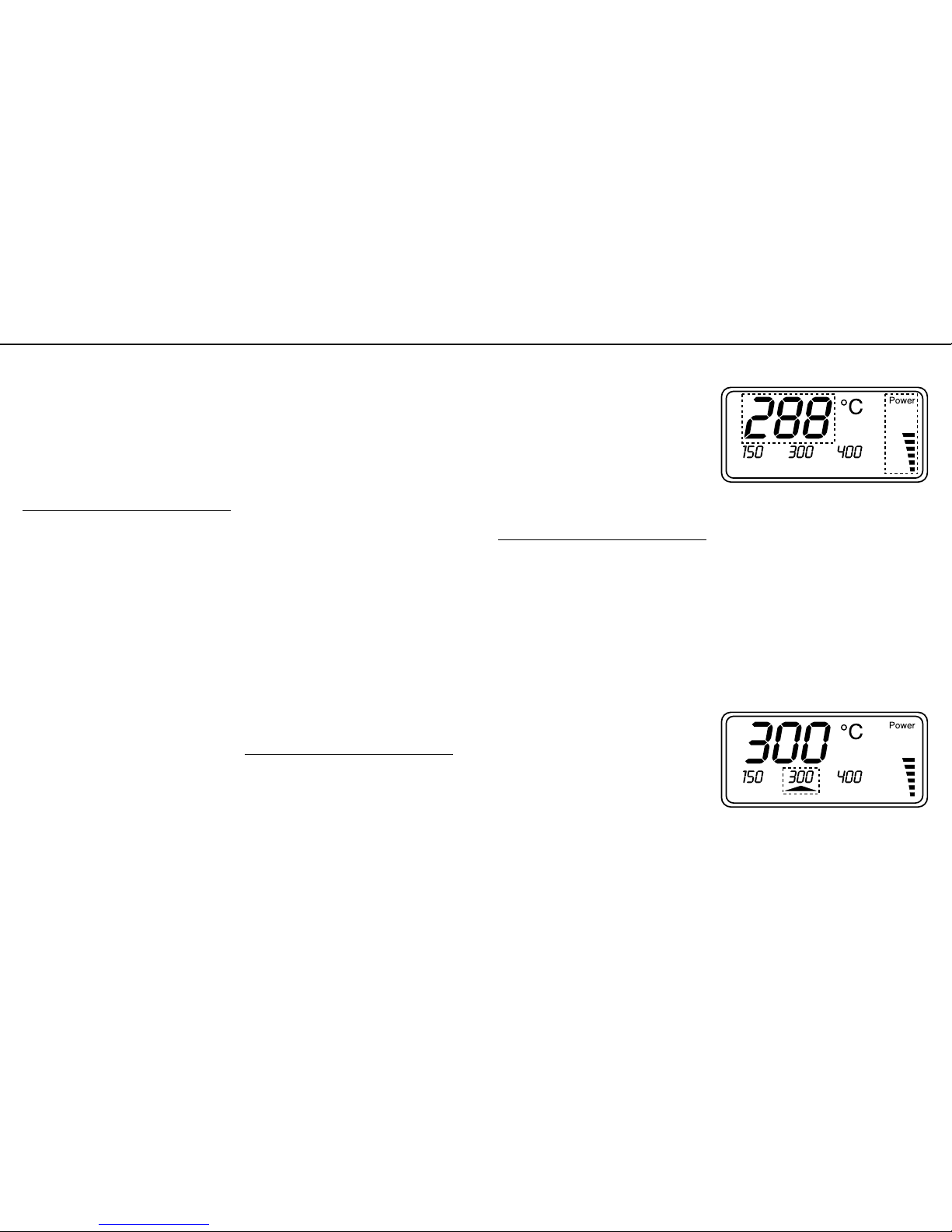

Press “Power” to switch on. The processor will

perform a display test by activating all 108 segments

for approximately two seconds. The soldering

iron will then heat up to the set point temperature

when it was last used. The LCD shows the current

temperature in the main display and the “Power”

bar-chart (which can be disabled) indicates the heat

being supplied to the soldering iron; (see Figure 1).

The soldering iron tip is maintained at a constant

temperature when the set point temperature is

reached.

Figure 1

3. Adjusting the set point temperature

The main display section will change to show the set

point temperature when either the “+” or “-“ keys are

pressed. The temperature can be jogged up or down

in 1° steps or in 10° steps if the key is held. Release

key when the desired temperature is reached.

4. Selecting one of the programmed set

point temperatures

The station is pre-programmed with three set

point temperatures, 150°C, 300°C and 400°C,

and displayed directly above the corresponding

“T1”/”T2”/”T3” keys. The main display shows the

new set point temperature for approximately three

seconds when the relevant key is pressed;

(

see Figure 2

).

Figure 2

5. Modifying the programmed set point

temperatures

To change the programmed set point temperatures,

use the “+”/”-“ keys whilst holding down the

appropriate “T1”/”T2”/”T3” key. The new temperature

will be saved as soon as the keys are released.