1

DOC# T0001 8.11.2014 DFC-X O&M

4380 Oakes Road, Suite 804

Email:info@RTC-Solutions.com

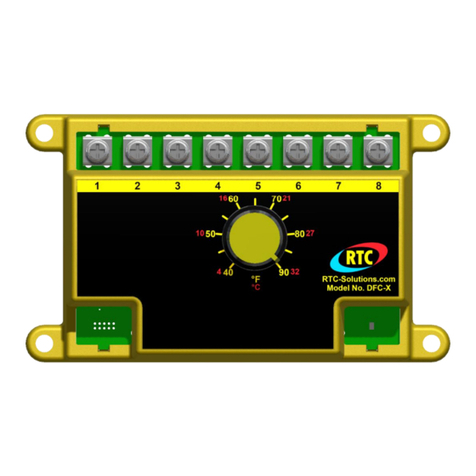

Model No. DFC-X

DIRECT FIRED DIGITAL TEMPERATURE CONTROL INSTALLATION,

OPERATION, AND MAINTENANCE MANUAL

This manual covers the following products:

Standard direct fired temperature control 0-24VDC output

Direct fired control with integral 40-90°F (4-32°C) dial 0-24VDC output

Temperature senor 40-250°F (4-121°C)

Temperature dial 5 selectable ranges

PWM to 10V output converter

Table of Contents

Overview.....................................................................................................................................................................................................................................................2

Specifications..............................................................................................................................................................................................................................................2

Power Requirements..............................................................................................................................................................................................................................2

DFC Ambient Temperature Limits ......................................................................................................................................................................................................2

DFTS/DFTD Ambient Temperature Limits .......................................................................................................................................................................................2

Accuracy..................................................................................................................................................................................................................................................2

Installation ..................................................................................................................................................................................................................................................2

Wiring..........................................................................................................................................................................................................................................................2

Standard control with remote setpoint................................................................................................................................................................................................2

Standard control with integral setpoint ..............................................................................................................................................................................................4

Optional room space control ................................................................................................................................................................................................................4

Optional multiple setpoint temperature control ................................................................................................................................................................................5

Operation ....................................................................................................................................................................................................................................................6

Start up .................................................................................................................................................................................................................................................... 6

Sequence of operation............................................................................................................................................................................................................................6

Calibration ..............................................................................................................................................................................................................................................6

Troubleshooting .....................................................................................................................................................................................................................................6

DFTS and DFTD Resistance chart ........................................................................................................................................................................................................6