How to Use This Manual.....................................................................................................................................1

Labels ..................................................................................................................................................................................... 1

Reference Information.......................................................................................................................................1

Serial Number .................................................................................................................................................................... 1

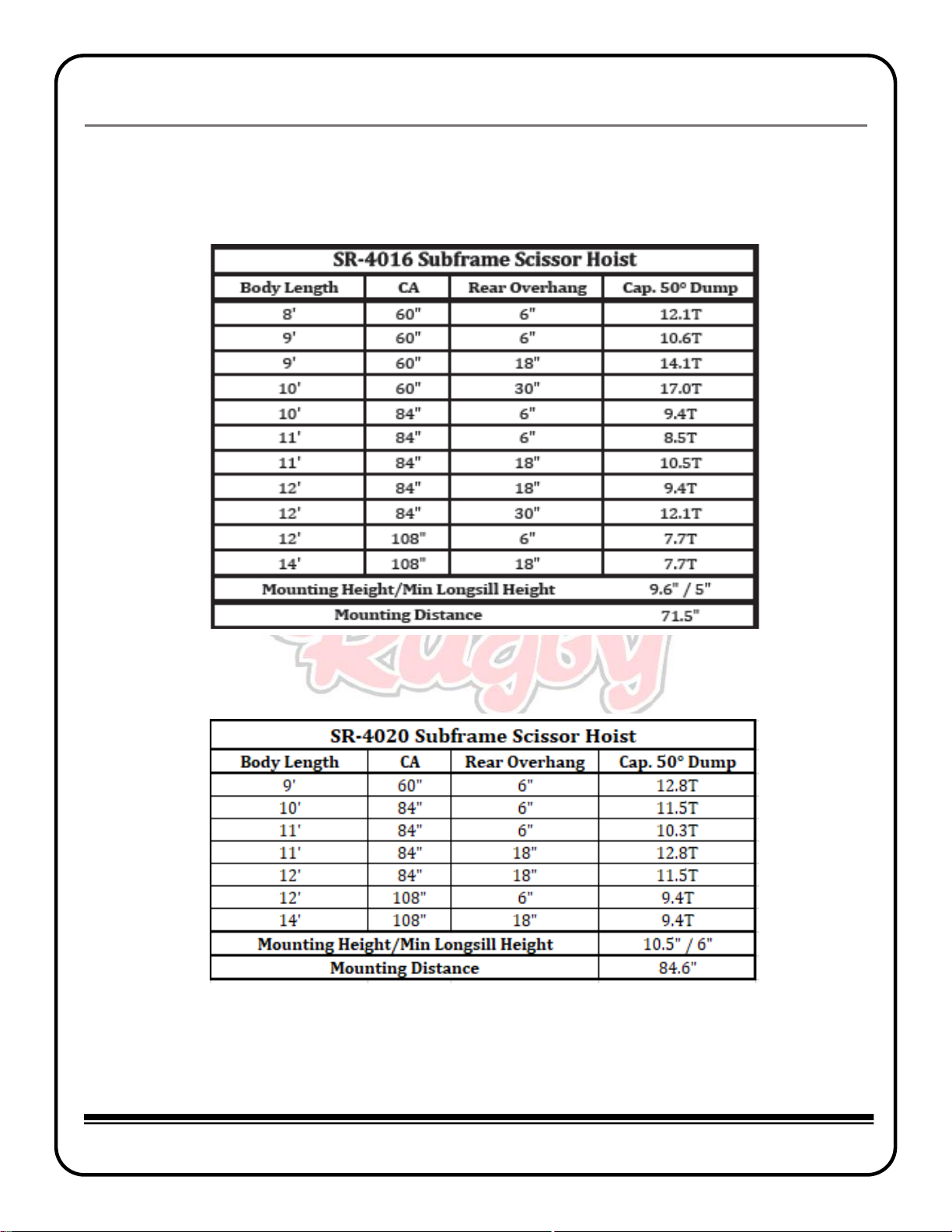

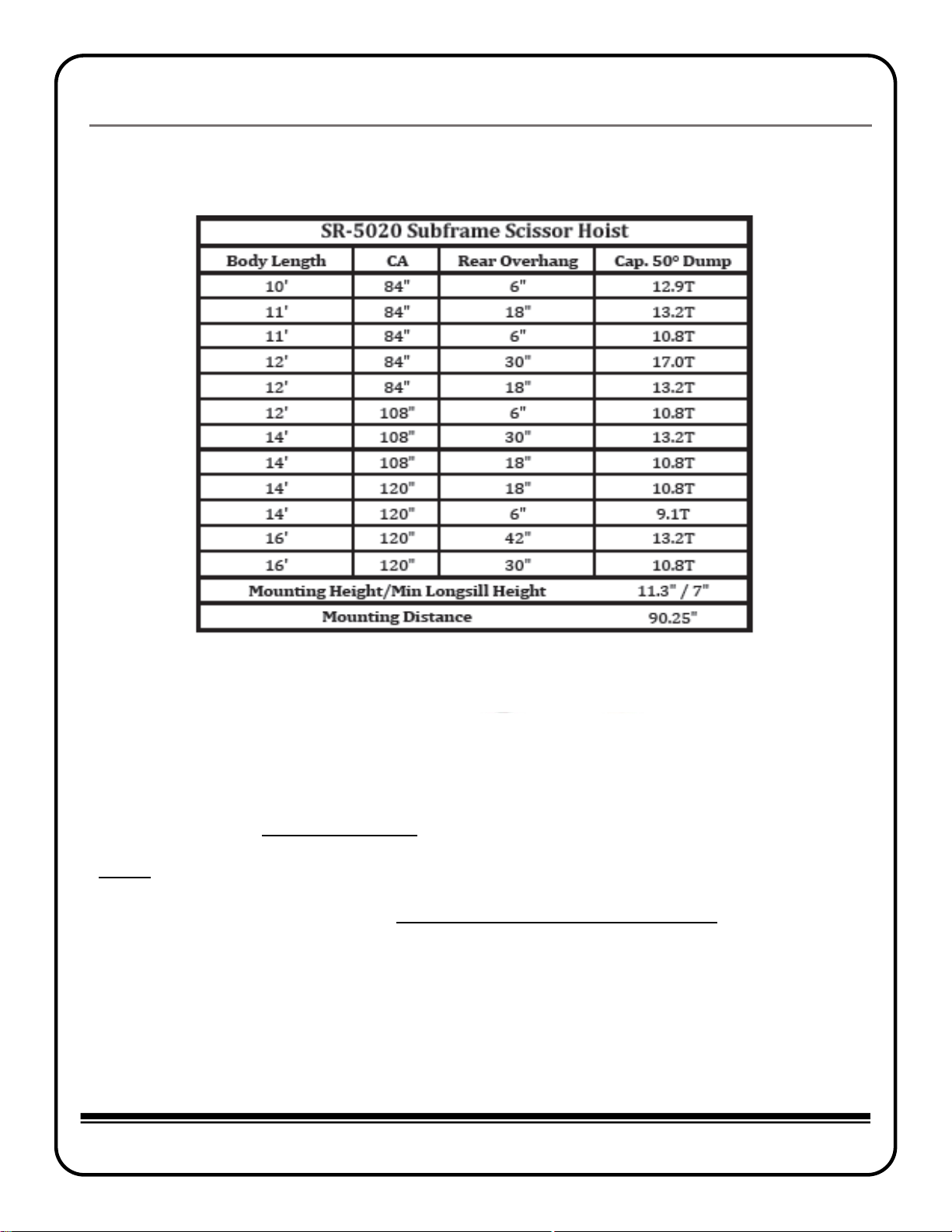

Capacity Chart..................................................................................................................................................................... 2

Torque Values Chart ....................................................................................................................................................... 4

Body Prop Application Chart........................................................................................................................................ 4

Hydraulic System............................................................................................................................................................... 5

Assembly & Installation.....................................................................................................................................6

Body Prop Installation.................................................................................................................................................... 6

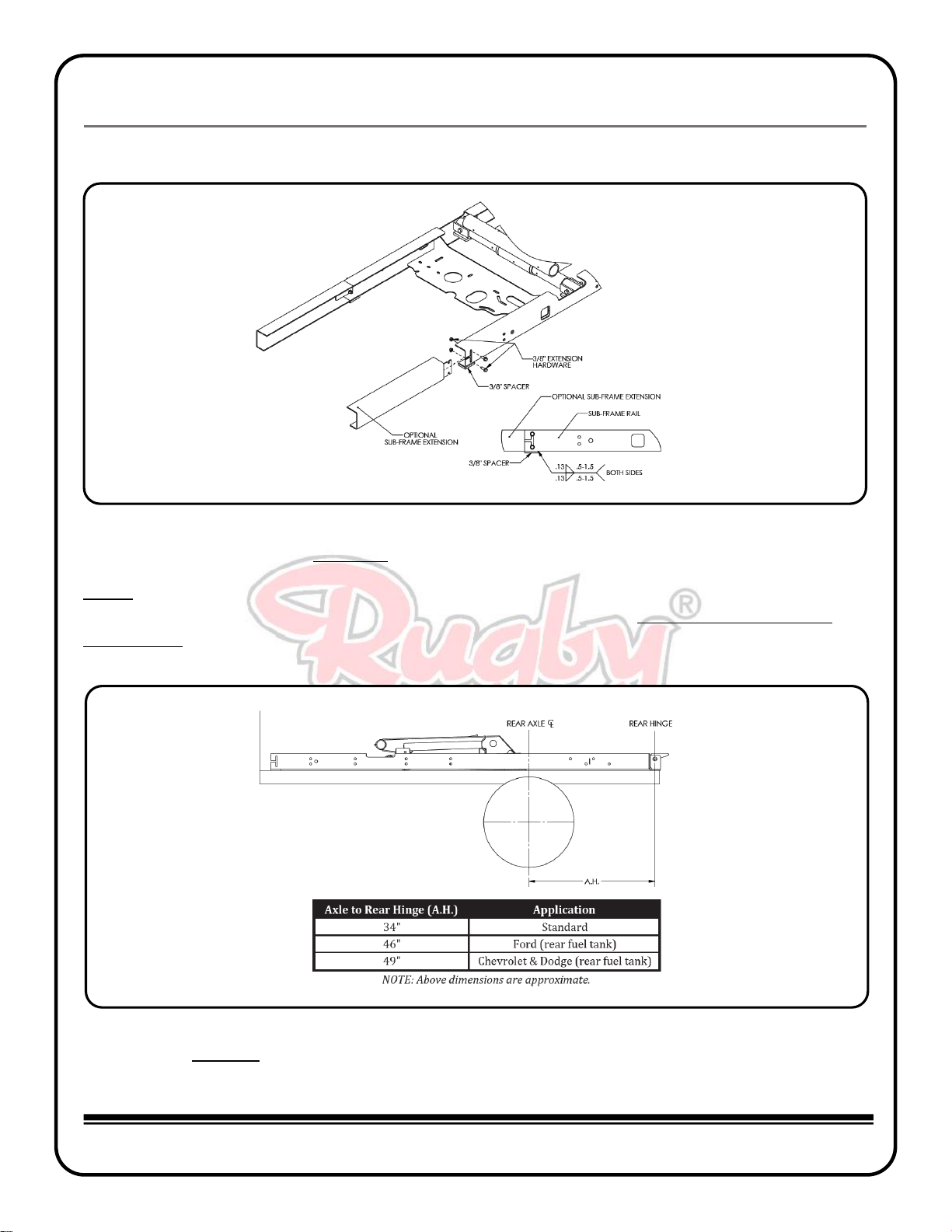

Hoist & Sub-frame Assembly ....................................................................................................................................... 7

Hoist & Sub-frame Installation.................................................................................................................................... 8

45° Application Sub-frame Modification...............................................................................................................14

Decal Locations.................................................................................................................................................................15

Operation.............................................................................................................................................................16

Body Prop Operation......................................................................................................................................................16

Maintenance........................................................................................................................................................16

Diagrams..............................................................................................................................................................17