Cutting machine SR 1 / SR 1 Turbo

2

Table of Contents

1 Safety Instructions............................................................................. 3

1.1 Safety instructions ................................................................... 3

1.2 Remaining risk of accidents .................................................. 6

1.3 Intended Use............................................................................... 7

2 Installation instructions.................................................................... 7

2.1 Machine transport and setup ............................................... 8

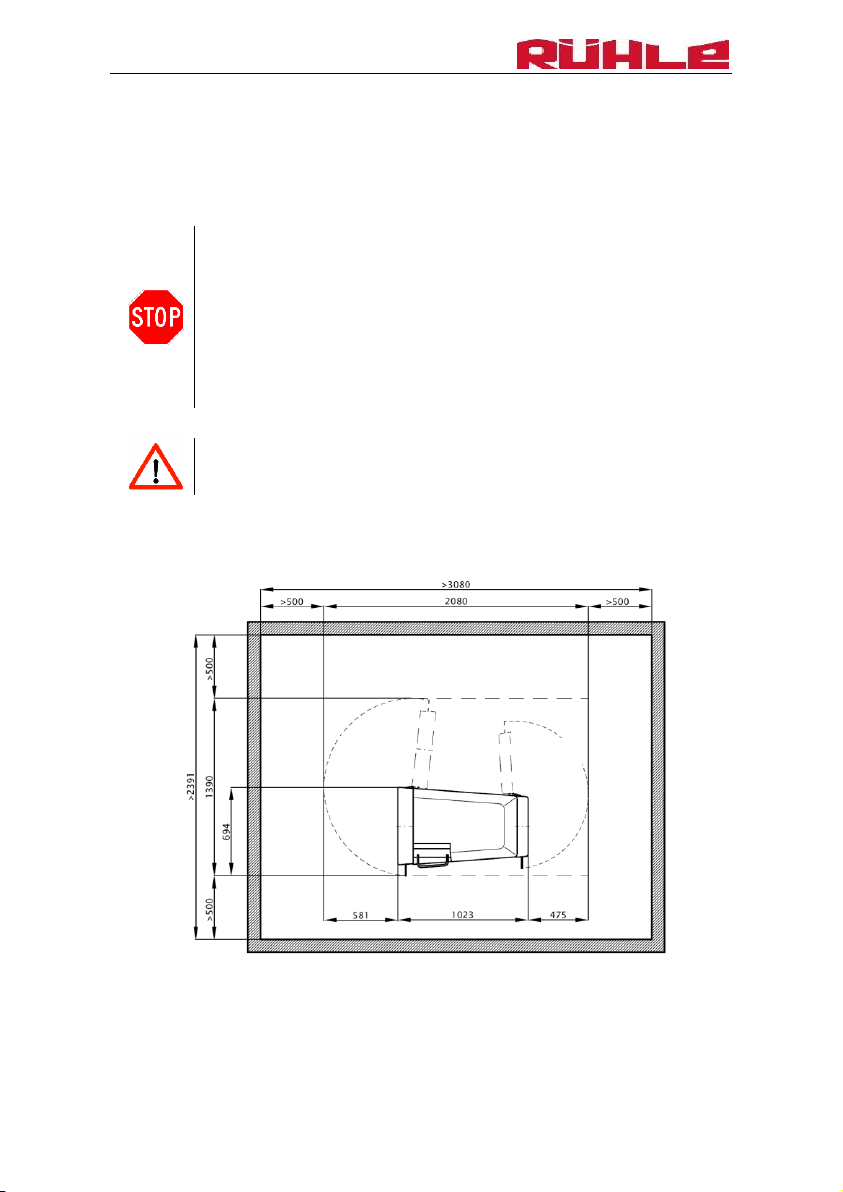

2.2 Workplace description............................................................. 8

2.3 Connecting the machine ......................................................... 9

3 Operating instructions ....................................................................10

4 Cleaning instructions.......................................................................11

4.1 Safety instructions .................................................................11

4.2 Cleaning agents and disinfectants....................................12

4.3 Cleaning procedure.................................................................12

5 Service: Care, maintenance, repair.............................................13

5.1 Regular care ..............................................................................14

5.2 Regular maintenance.............................................................15

5.3 Repair and spare parts..........................................................15

6 Disposal................................................................................................16

7 Technical documentation ..............................................................16

7.1 Technical data ..........................................................................16

7.2 Electrical circuit diagram ......................................................17

8 EC Declaration of Conformity according to Directive

2006/42/EC [for SR 1]....................................................................18

9 EC Declaration of Conformity according to Directive

2006/42/EC [for SR 1 Turbo].......................................................19

Status: 14/09/2016

Changes reserved