2

Contents Page

1. Safety instructions ...........................................................................................................................................3

1.1 Safety hints..........................................................................................................................................................3

1.2 Safety data sheet.............................................................................................................................................4

2. Installation instructions ................................................................................................................................6

2.1 Machine installation................................................................................................................................... .7

2.2 Connection of the Machine.......................................................................................................................7

2.3 Commissioning of the machine................................................................................................................8

3. Operating instructions ...............................................................................................................................9

3.1 Switching on the machine..........................................................................................................................9

3.2 Cutting preparation....................................................................................................................................10

3.3 Cut adjustments. ..........................................................................................................................................10

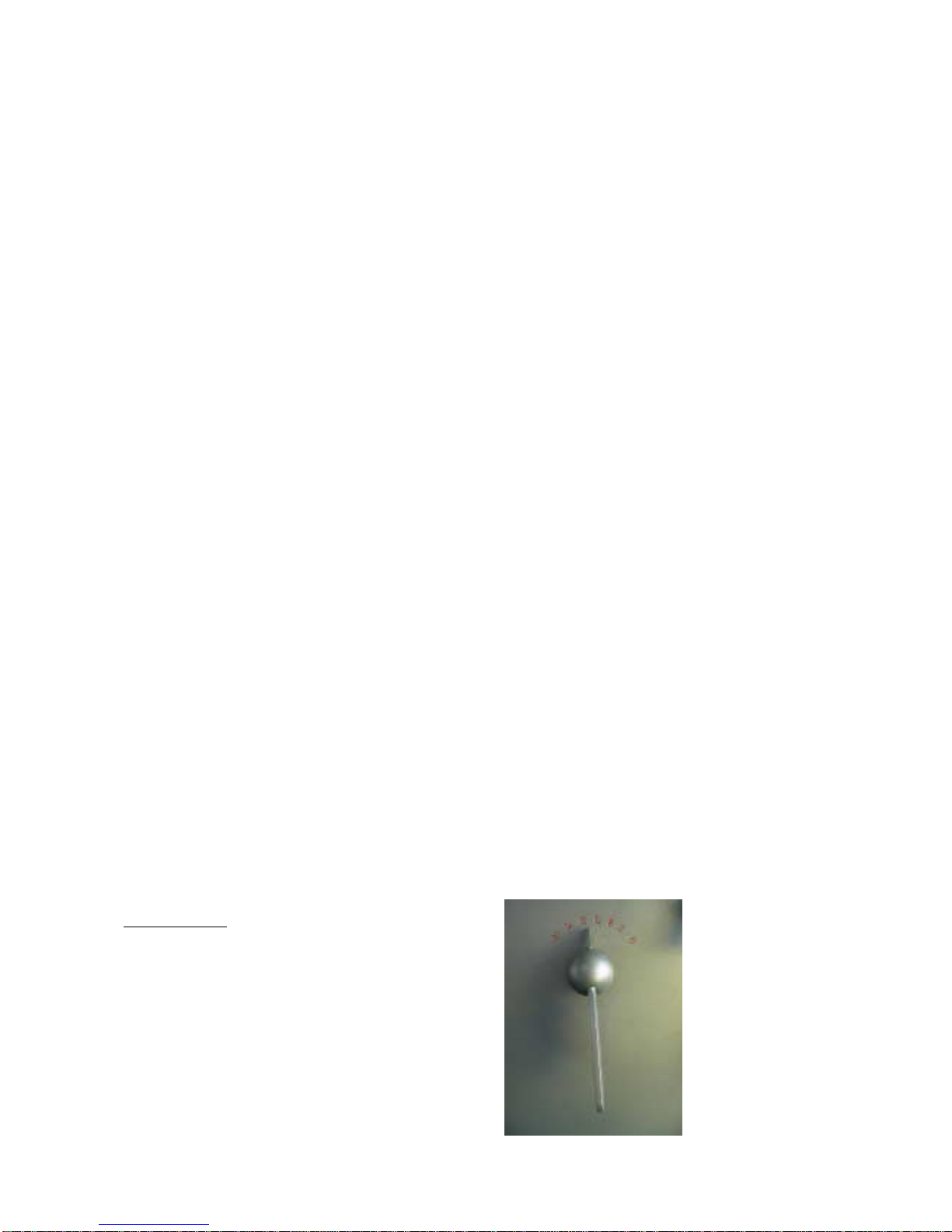

3.4 The HighTech-cutter..................................................................................................................................16

3.4.1 HighTech-cutter selection..........................................................................................................................17

3.4.2 HighTech-cutter assembly........................................................................................................................17

3.4.3 HighTech-cutter installation.....................................................................................................................19

3.4.4 HighTech-cutter maintenance................................................................................................................20

3.5 The sectioning Blade................................................................................................................................20

3.6 The Tool box................................................................................................................................................21

3.7 Feeding the machine...............................................................................................................................22

3.7.1The work bench............................................................................................................................................22

3.7.2The shaft – charging..................................................................................................................................22

3.8 Product discharge.......................................................................................................................................23

3.8.1 The use of boxes........................................................................................................................................23

4. Cleaning instructions.................................................................................................................................24

4.1 Safety hints.....................................................................................................................................................24

4.2 Cleaning agents and disinfectants...................................................................................................24

4.2 Cleaning procedure...................................................................................................................................25

5. Technical service........................................................................................................................................26

5.1 Regular maintenanace...........................................................................................................................26

5.2 Regular servicing........................................................................................................................................27

5.3 Errors ...............................................................................................................................................................28

6. Technical documentation...............................................................................................29

6.1 Circuit diagrams.........................................................................................................................................29

6.2 List of spare parts.....................................................................................................................................29

7. Index............................................................................................................................................................30