18

GUARANTEE

All tools manufactured by RUPES Spa are guaranteed for 12 months from the

date of purchase against fabrication and material defects.

The guarantee will no longer be valid if the instructions contained in this booklet

are not followed, if the tool is used for purposes other than that for which it is

intended, if it is dismantled, interfered with in any way or damaged due to neglect.

The guarantee will be made valid by filling-in the form on the inside back

cover of this instruction booklet.

If the tool is found to be defective or malfunctions, it should be returned

carriage free in one piece in its original packing together with the guarantee

certificate to the manufacturer or to one of the Assistance Centres listed in the

appendix to this booklet.

The guarantee does not automatically imply replacement of the tool.

RUPES Spa reserve the right to carry out modifications to the tool without

prior notice.

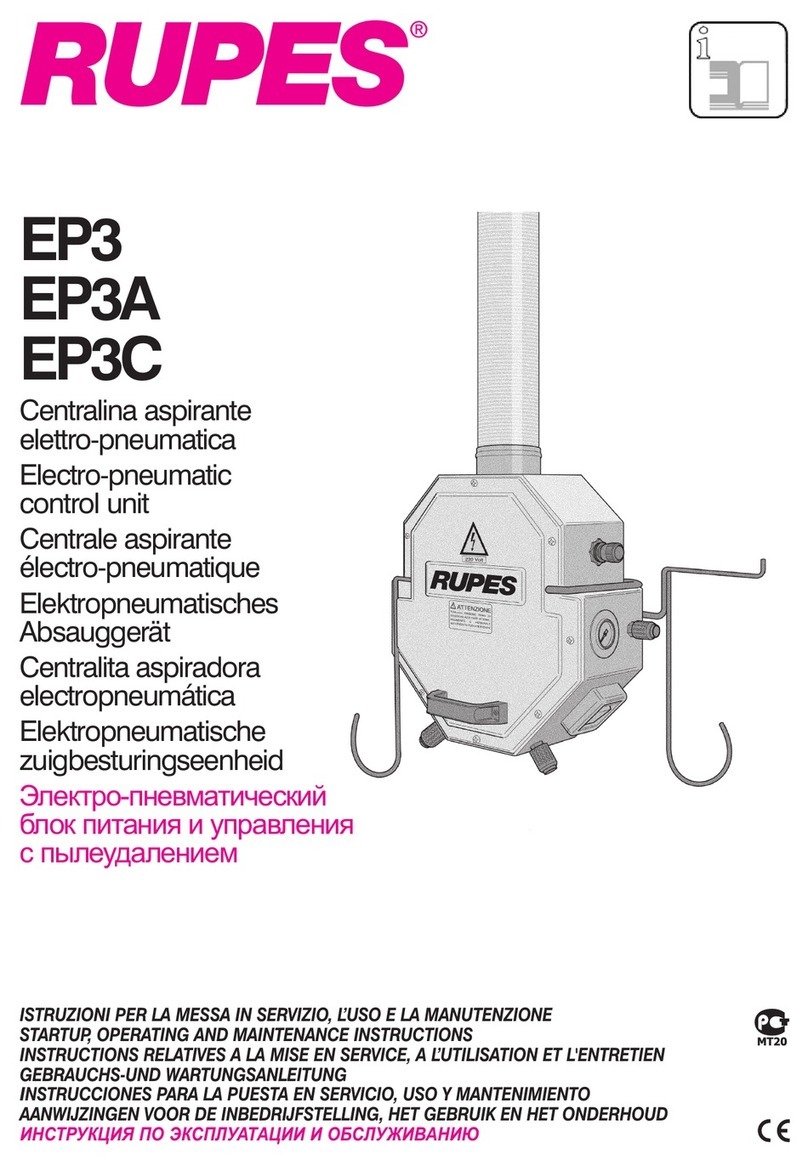

TOOL IDENTIFICATION PLATE

POSITION AND MEANING OF INFORMATION

1. Type of machine

2. Operating pressure

3. Absorbed current

4. Voltage

5. Serial number

GARANZIA

Tutte le macchine costruite dalla RUPES Spa sono garantite per 12 mesi dalla

data di acquisto contro difetti di materiale e di fabbricazione. La garanzia decade

qualora non vengano rispettate le prescrizioni del presente libretto o qualora

venga fatto uso improprio della macchina. Decade altresì se la macchina viene

smontata o manomessa o se vi sono evidenti danni derivanti da cattiva cura

della stessa.

La garanzia è subordinata alla compilazione del tagliando riportato sull’ultima

pagina di copertina del presente libretto d'istruzioni.

In caso di accertato malfunzionamento la macchina, accompagnata dal certificato

di garanzia, dovrà essere consegnata o spedita franco di porto, non smontata e

nell'imballo originale, al fabbricante o ad un Centro di Assistenza autorizzato

riportato nell'elenco allegato al presente libretto.

In ogni caso la garanzia non dà diritto alla sostituzione della macchina.

La RUPES Spa si riserva di apportare modifiche alle macchine senza preavviso.

TARGHETTA DI IDENTIFICAZIONE DELLA MACCHINA

POSIZIONAMENTO E SIGNIFICATO DEI DATI

1. Tipo della macchina

2. Pressione di esercizio

3. Assorbimento

4. Voltaggio

5. Numero di matricola o di serie della macchina

GARANTIE

Toutes les machines construites par la Société RUPES Spasont garanties pendant

12 mois à compter de la date d’achat contre les défauts matériau et de fabrication.

La garantie prend fin en cas de non-respect des prescriptions du présent livret

ou en cas d’utilisation impropre de la machine. Elle prend fin également si la

machine est démontée ou modifiée ou en cas de dommages évidents dérivant

d’un mauvais entretien.

La garantie est subordonnée au remplissage du coupon qui se trouve à la derniére

page de couverture du présent livret d’instructions.

En cas de mauvais fonctionnement, la machine, accompagnée de son certificat

de garantie, devra être remise ou envoyée en port payé, non démontée et dans

son emballage d’origine, au fabricant ou à un Centre d’Assistance agrée indiqué

sur la liste annexée au présent livret.

La garantie ne donne pas en aucun cas droit au remplacement de la machine.

La Société RUPES Spa se réserve la faculté d’apporter sans préavis des

modifications aux machines.

PLAQUETTE D’IDENTIFICATION DE LA MACHINE

EMPLACEMENT ET SIGNIFICATION DES DONNEES

1. Type de machine

2. Pression de fonctionnement

3. Courant absorbé

4. Voltage

5. Numéro de matricule ou de série de la machine

GARANTIA

Todas las máquinas fabricadas por RUPES Spa están garantizadas durante

12 meses a partir de su fecha de compra, contra defectos tanto de materiales,

como de fabricación.

La garantía caduca si no se respetan las prescripciones del presente manual o

si la máquina se usa de manera impropia. También caduca si la màquina es

desmontada o abierta abusivamente o si presenta daños derivados del maltra-

to de la misma.

La garantìa està subordinada al relleno del cupón incluido en la ùltima de

tapa del presente manual de instrucciones.

En caso de comprobado mal funcionamiento, la máquina, acompañada del certifica-

do de garantía, deberá entregarse o enviarse con porte pagado, sin dismontarla

y en su embalaje original, a la fábrica o a un Centro de Asistencia autorizado indi-

cado en la lista adjunta al presente manual.

En ningùn caso la garantía da derecho a la substitución de la máquina.

RUPES Spa se reserva el derecho de aportar modificaciones a las máquinas

sin aviso previo.

PLACA DE IDENTIFICACION DE LA MAQUINA

POSICION Y SIGNIFICADO DE LOS DATOS

1. Tipo de máquina

2. Presión de operación

3. Absorción

4. Voltaje

5. Número de matrícula o de serie de la máquina

GARANTIE

Für alle von ihr hergestellten Geräten leistet die Fa. RUPES Spa Gewähr bei

von Mängeln, die innerhalb von 12 Monaten ab dem Kaufdatum aufgrund

Material-oder Fabrikationsfehlern auftreten .

Der Garantieanspruch entfällt bei unsachgemäßem Gebrauch des Gerätes oder

der Nichteinhaltung dieser Gebrauchsanleitung.

Er entfällt ebenfalls, wenn das Gerät demontiert bzw. umgerüstet wurde oder

sichtbare Schäden infolge mangelhafter Pflege aufweist.

Die Inansprunchnahme der Garantieleistung ist nur möglich, wenn der

Abschnitt auf der vorletzten Umschlagseite dieser Gebrauchsanleitung

ausgefüllt ist.

Im Fall einer nachweislichen Funktionstörung muß das Gerät dem Hersteller

komplett montiert, originalverpackt und mit beiliegender Garantiekarte fracht und

portofrei übergeben bzw. zugesendet werden. Die Übergabe an ein autorisiertes

Kundendienstzentrum (siehe beiliegendes Verzeichnis) ist ebenfalls möglich.

In keinem Fall leitet sich aus dem Garantieanspruch ein Rechtsanspruch auf die

Ersetzung des Gerätes ab.

Die Fa. RUPES Spa behält sich das Recht vor, ohne Vorankündigung techni-

sche Änderungen an ihren Geräten vorzunehmen.

KENNDATENSCHILD DES GERÄTES

ANORDNUNG UND BEDEUTUNG DER ANGABEN

1. Gerätetyp

2. Betriebsdruck

3. Leistungsaufnahme

4. Spannung

5. Geräte- oder Seriennummer

GARANTIE

Op alle machines die door RUPES Spa gemaakt zijn wordt vanaf de datum

van aankoop 12 maanden garantie verleend, tegen fabrieks- en materiaalfouten.

De garantie vervalt indien de aanwijzingen die in de gebruiksaanwijzing staan

niet opgevolgd zijn of indien de machine voor andere doeleiden gebruikt is

dan waarvoor de machine bedoeld is. De garantie vervalt ook als de machine

uit elkaar gehaald wordt of gemanipuleerd wordt of als er beschadigingen zijn

die duidelijk te wijten zijn aan slecht onderhoud ervan.

De garantie gaat in wanneer de coupon die op de laatste bladzijde van de

omslag staat ingevuld is.

Wanneer de machine defect is of niet correct functioneert moet de machine niet

gedemonteerd en in de oorspronkelijke verpakking ingeleverd worden bij of franco

teruggestuurd worden naar de fabrikant of een officieel servicecentrum dat op de

lijst die bij dit boekje gevoegd is staat. In ieder geval geeft de garantie geen recht

op vervanging van de machine. RUPES Spa behoudt zich het recht voor om zon-

der voorafgaand bericht wijzigingen aan de machines aan te brengen

.

TYPEPLAATJE VAN DE MACHINE

PLAATS EN BETEKENIS VAN DE GEGEVENS

1. Typ.

2. Bedrijfsdruk

3. Stroomopname

4. Voltage en frequentie

5. Machinecode of serienummer.

I

GB

F

E

D

ND

TYPE

15

234

MILANO - ITALY

TYPE

15

234

MILANO - ITALY

TYPE

15

234

MILANO - ITALY