4

Jr.

Sodcutter

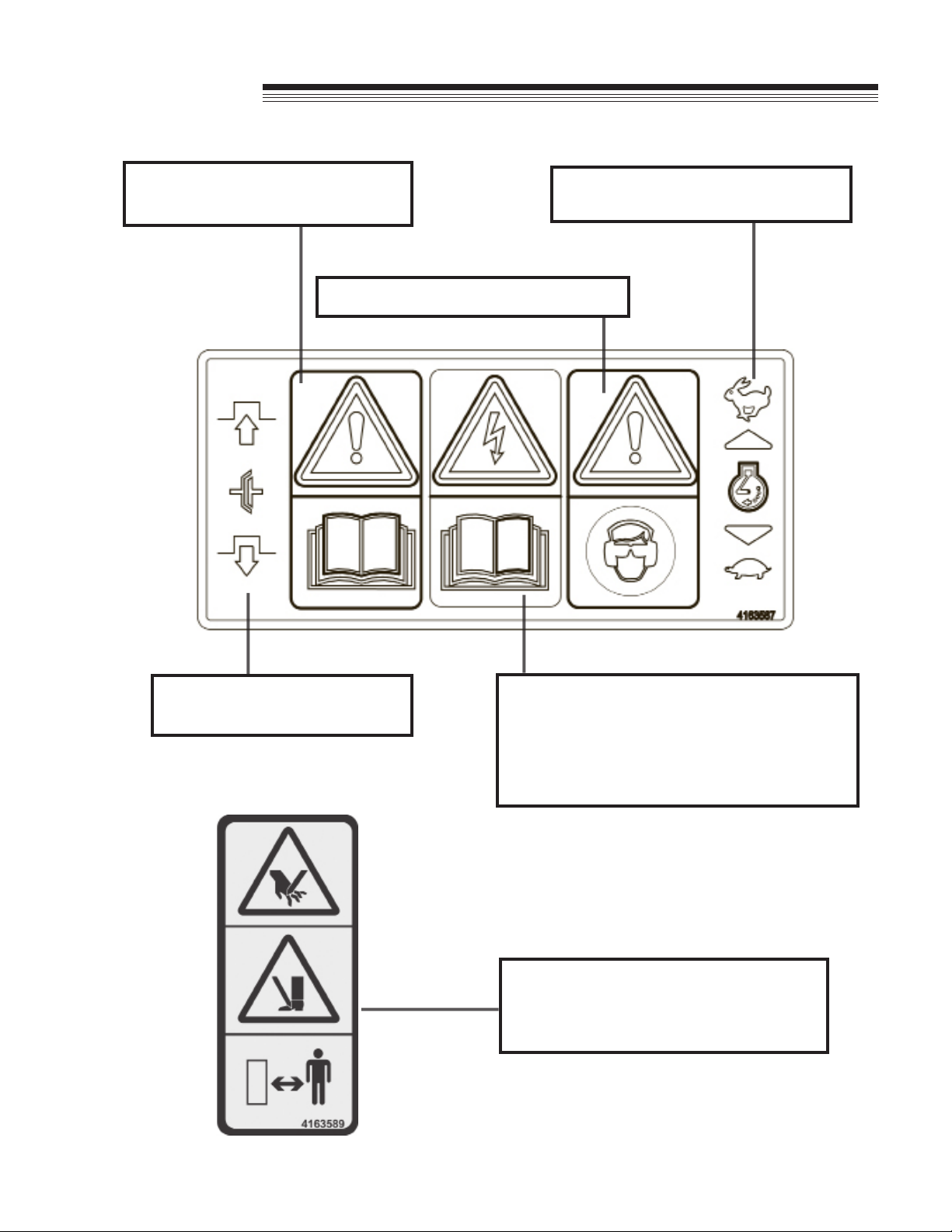

OPERATING SAFELY

IN GENERAL

– Use extra care when loading or unloading the

machine into a trailer or truck.

– Use caution when making turns and crossing

roads and sidewalks. Stop blade when not

cutting sod.

– Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

– Never leave a running machine unattended.

Always turn off blade and stop engine when

leaving the operator position. When leaving

the machine be sure the wheel drive clutch is

engaged.

– Use extreme caution when reversing or pulling

machine towards you.

– Stop operation if someone approaches.

– Never leave a running machine unattended.

Always disengage drive, and stop engine.

STARTING

– Start according to instructions in this manual or

on the machine.

– Before attempting to start the engine, make sure

the master clutch is disengaged.

_ When starting the engine, make sure hands and

feet are clear of the blade.

– Do not change engine governor settings or

overspeed the engine. Operating the engine

at excessive speed can increase the hazard of

personal injury.

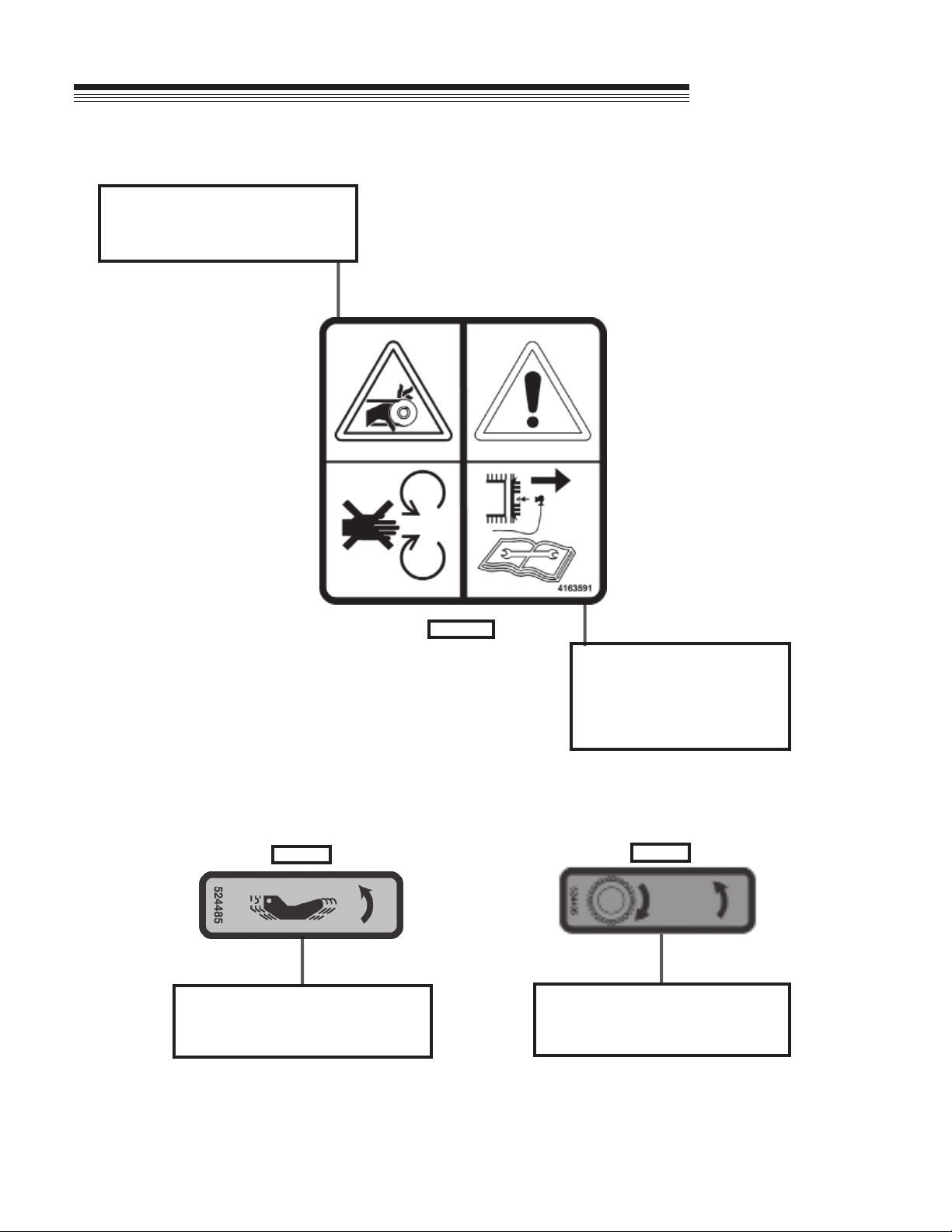

INTERRUPTING OPERATION

- Before leaving the operator's position:

- Park on level ground.

- Disengage the master clutch.

- Shut off the engine.

- Disengage the master clutch and wait until the

blade stops moving then disengage the blade

clutch:.

- when not cutting sod;

- for transport;

- when crossing surfaces other than grass.

- Disengage the master clutch, stop the engine,

and wait until the blade stops moving:

- before refueling;

- before making blade adjustment .

- Disengage the master clutch, stop the engine,

and disconnect the spark plug wire(s):

- before clearing blockages;

- before checking, cleaning or working on the

machine;

- after striking a foreign object. Inspect the

machine for damage and have repairs made

before restarting;

- if the machine begins to vibrate abnormally:

shut off machine immediately. Inspect

and have repairs made as needed before

restarting;

- except for repairs or adjustments as specically

noted, such as for carburetor adjustment,

where the engine must be running. Keep

hands and feet clear of moving parts in these

circumstances.

- Allow the blade to come to a complete stop when

stopping operation to clear blockages, unclog,

inspect the machine, do maintenance or repair.

- Reduce the throttle setting during engine shut-

down and, if the engine is provided with a shut-

off valve, turn the fuel off at the conclusion of

operation.

SAFETY

OPERATING ON SLOPES

- Slopes are a major factor in loss of control and tip

over accidents that sometimes lead to severe injury

or death. All slopes require extra caution.

- Before operating on slopes, evaluate the risks

involved.

- Do not operate on slopes if uneasy or uncertain.

Ultimate responsibility for safe operation on slopes

rests with the operator.

- Do not operate on steep slopes.

- Keep all movement on slopes slow and gradual.

- Do not cut sod near drop-offs, ditches or embank-

ments. The machine could suddenly turn over if a

wheel runs over the edge or an edge caves in.

- Do not turn on slopes unless necessary, and then

turn slowly and downhill when possible.

- Be sure of your footing on slopes.

- With walk behind machines, operate across slopes,

not up and down.

- Avoid starting or stopping on a slope. If wheels lose

traction, disengage the cutter blade and proceed

straight down the slope.