3

Safety, performance, and dependability have

been given top priority in the design of your

blower.

INTENDED USE

The blower is only intended for use outdoors

in dry and well-illuminated conditions.

The product is not intended to be used by

children or persons with reduced physical,

mental, or sensory capabilities.

The product is designed for blowing light

debris, such as leaves, grass, and other

garden refuse.

When used with the vacuum kit, it is intended

to vacuum and mulch debris and deposit it

into the collection bag. The RAC3010 vacuum

kit is sold separately.

The product is not designed to suck in water

or other liquids.

Do not use the product for any other purpose.

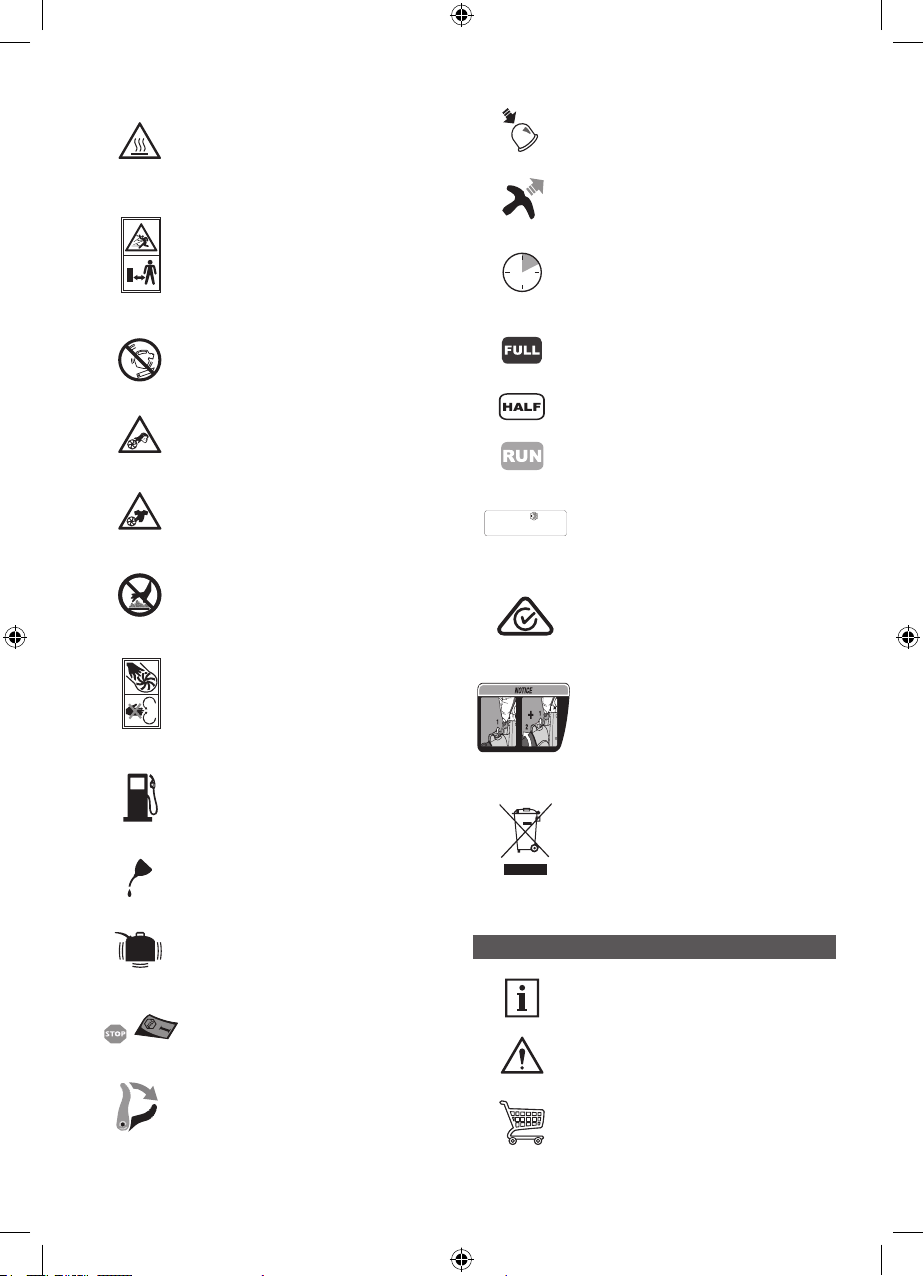

GENERAL SAFETY WARNINGS

WARNING

Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

re, and/or serious injury. Save all warnings

and instructions for future reference.

WARNING

Never allow children or people unfamiliar

with these instructions to use the product.

Local regulations may restrict the age of the

operator.

■Some regions have regulations that restrict

the use of the product. Check with your

local authority for advice.

■Do not allow children or untrained

individuals to use the product.

■Ensure before each use that all controls

and safety devices function correctly. Do

not use the product if the off switch does

not stop the engine.

■Never start or run the engine in a closed or

poorly ventilated area; breathing exhaust

fumes can kill.

■Clear the work area before each use.

Remove all objects such as rocks, broken

glass, nails, wire, or string that can be

blown a considerable distance by high

velocity air. Wear hearing protection at

all times while operating the product. The

product is noisy, and permanent hearing

injury may result if precautions to limit your

exposure, reduce noise, and wear hearing

protection are not strictly adhered to.

■Wear full eye protection at all times while

operating the product. The manufacturer

strongly suggests a full face mask or fully

enclosed goggles. Normal spectacles or

sunglasses are not adequate protection.

Objects can be thrown at high speed by

the powerful air jet at any time and may

rebound from hard surfaces toward the

operator.

■While operating the product, always wear

substantial footwear and long trousers.

Do not operate the product when barefoot

or wearing open sandals. Avoid wearing

clothing with loose fitting or that has

hanging cords or ties.

■Do not wear loose clothing or jewellery that

can be drawn into the air inlet. Secure long

hair so it is above shoulder level to prevent

entanglement in moving parts.

■Beware of thrown objects; keep all

bystanders, children, and pets at least 15

m away from the work area.

■Operate the product only at reasonable

hours – not early in the morning or late at

night when people might be disturbed.

■Use rakes or brooms to loosen debris

before operating the product.

■Never operate the product in an explosive

atmosphere.

■Never use the product when you are tired,

ill, or under the influence of alcohol, drugs,

or medicine.

■Before each use, ensure that all controls

and safety devices function correctly.

■Operate the product in a recommended

position and only on a firm and level

surface.

■Do not operate the product on a paved

or gravel surface where ejected material

could cause injury.

■Before each use, always inspect the

housing for damage. Ensure that guards

and handles are in place and properly

secured. Replace worn or damaged

components in sets to preserve balance.