- 7 -

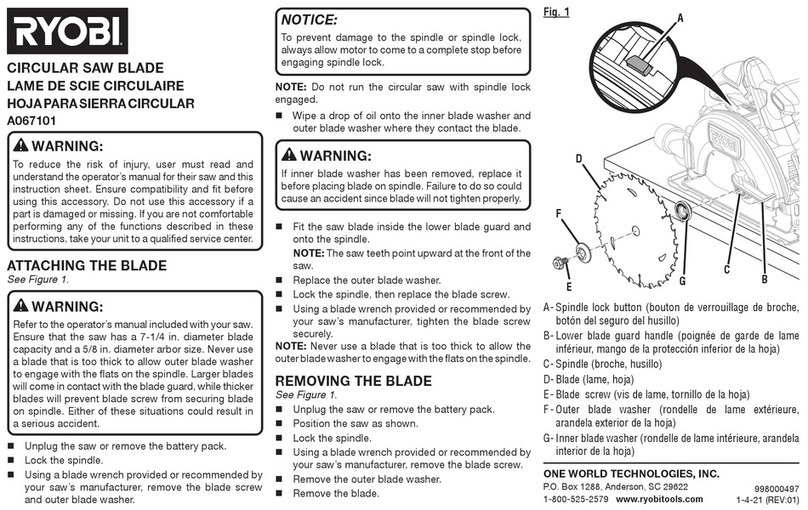

REMOVING BLADE (Fig.9)

WARNING: Disconnect band saw from power source

when changing or adjusting blades. Wear leather gloves

when handling band saw blades. Never wear gloves when

operating saw.

●Turn blade tension lever on the back of the tool

clockwise all the way until it locks in position to release

blade tension (see Figure 9).

●Release two latches on the side of the tool and open

upper and lower doors.

NOTE: When opening doors, make sure latches are

completely free from tabs on frame.

Remove table locking insert located in the front

of the table slot, take out the released blade and

replace with another blade.

INSTALLING BLADE

●Although most of the adjustments are not changed when

blade is removed, every adjustment should be checked

prior to using a newly installed blade.

●Make sure blade teeth are pointing down towards table.

Turn blade inside out if necessary.

●Slip new blade into table slot and over the upper and

lower blade wheels. Slide blade in between blade

guards.

●Tension blade by turning blade tensioning lever

counterclockwise, as far as it will go (see Figure 9).

●This is a spring loaded, tensioning mechanism and it will

automatically apply required tension to the blade.

● Use the tension knob to make ne adjustments to blade

tension.

●Close the doors and fasten latches.

●NOTE: When closing doors, make sure that the edges

attempting to secure door. This is necessary for proper

operation of dust collection system. The latches will not

pull the doors and frame together.

●Install table insert.

●Track blade as described in the following sections.

TRACKING BLADE

Refer to Figures 9 and 12.

WARNING: Be very careful; Improperly tracked blade

may spring out from wheels causing serious injury. Do not

perform tracking adjustment while band saw is running.

●Disconnect band saw from power source.

●To check the blade tracking, rotate drive wheel by hand

in clockwise direction. View blade through tracking

window.

●Proper tracking is achieved when driver and idler wheels

are aligned. Tracking knob on the back of the tool frame

is used to tilt upper wheel and align blade wheels.

●If blade rides away from cabinet, turn knob clockwise. If

blade rides toward cabinet, turn knob counterclockwise.

●When blade is tracking properly, secure position by

tightening nut.

BLADE GUIDES

NOTE: Adjust blade guides only after blade has been

properly tensioned and tracked.

●Blade guides support blade at sides and rear of blade,

and prevent twisting or deection.

●Blade guides should not touch blade when no workpiece

is in contact with blade. Adjust guides as described in

following section.

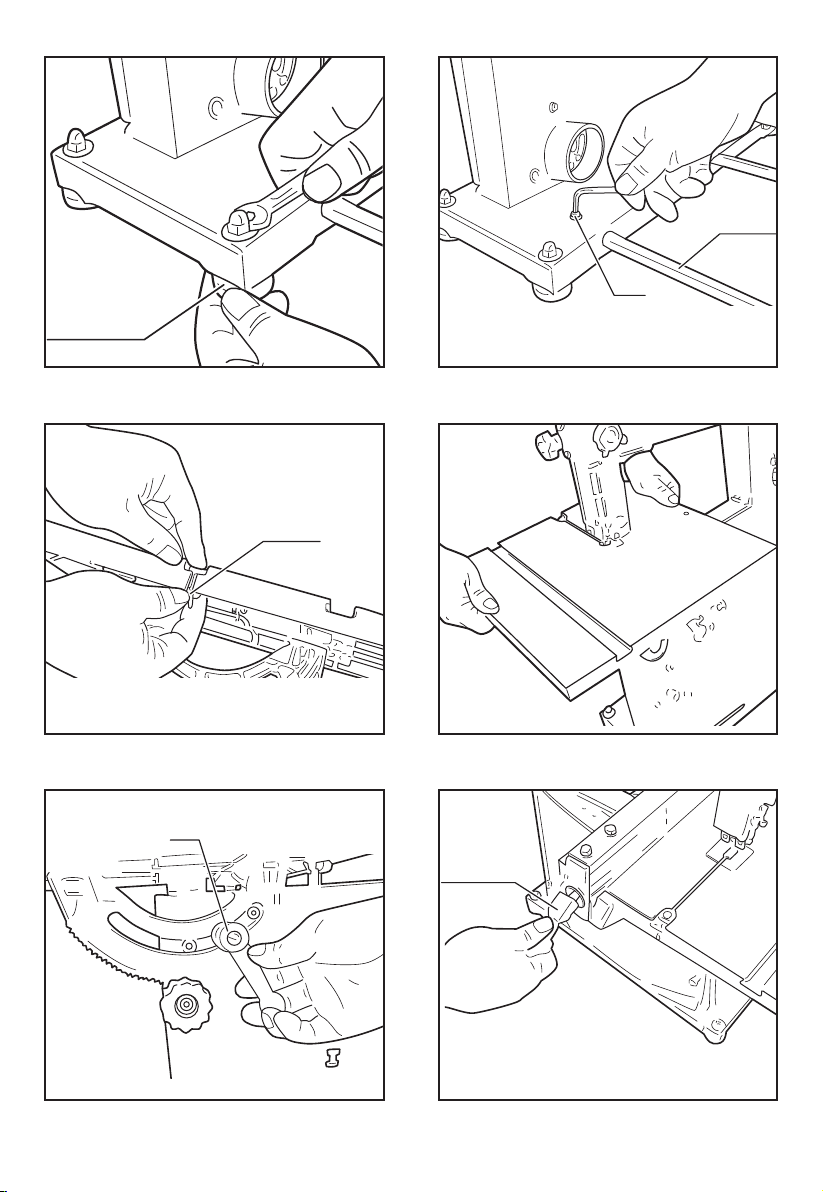

UPPER BLADE GUIDES (Fig.10-11)

●Upper blade guides employ guide pins for side support

and a ball bearing for rear support.

●Loosen screws and adjust guide pins to sides of the

blade (see Figure 10). Use a feeler gauge to check that

guide pins are 0.002” away from blade.

●Lock adjustment by tightening screw.

●Adjust ball bearing at rear of blade by loosening socket

head bolt and repositioning shaft (see Figure 11).

●Position ball bearing 0.002” away from back of blade.

●Secure position of bearing by tightening socket head

bolt.

●Adjust the height of upper guide to clear the workpiece

by 1/4”. Loosen upper guide knob and adjust height of

upper guide until it clears workpiece by 1/4”. Tighten

upper guide knob.

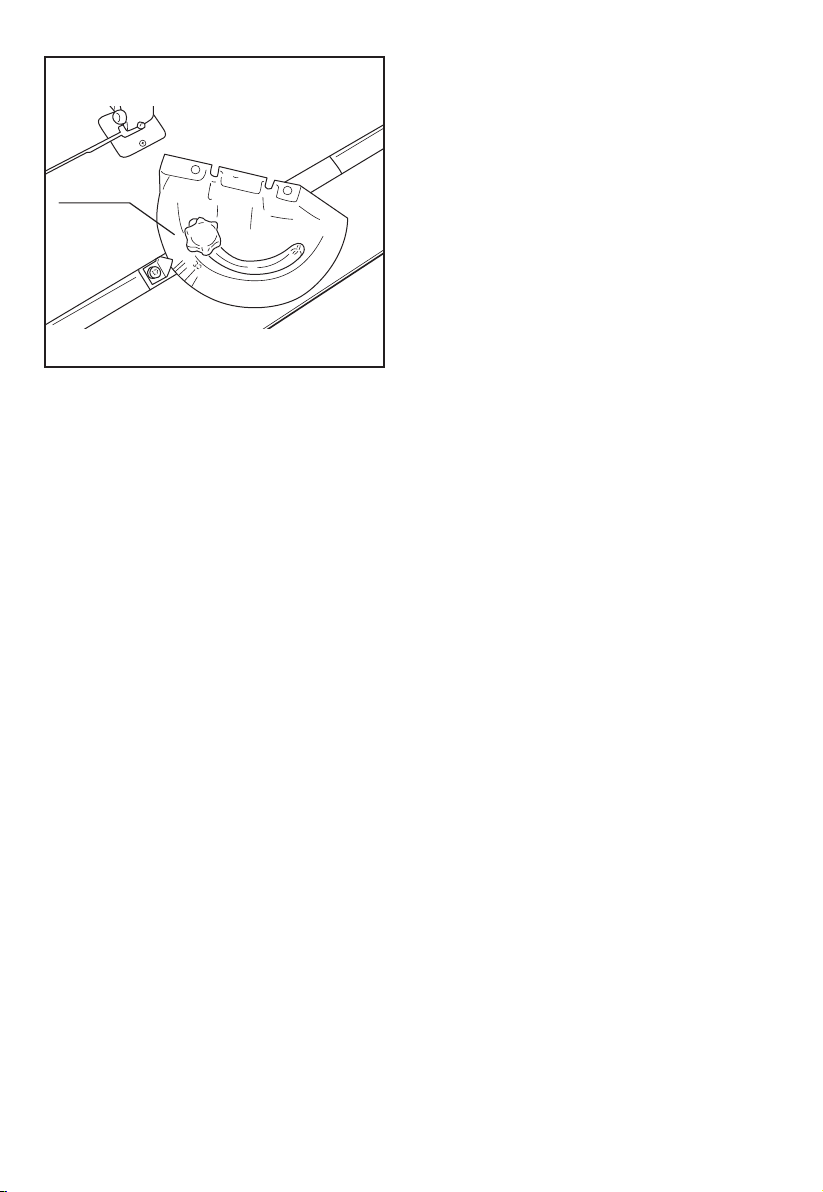

LOWER BLADE GUIDES (Fig.12)

●Lower blade guides employ guide pins for side support

and bearing for rear support.

●Loosen screws (see Figure 12) and move guide pins

away from blade sides.

●Loosen socket head bolts and adjust lower guide bracket

position so that rear of blade is positioned 0.002” away

from bearing.

●Tighten socket head bolts.

●Adjust guide pins to sides of the blade. Use a feeler

gauge to check that guide pins are 0.002” away from

blade.

●Lock adjustment by tightening screws.

BLADE SELECTION

●Blade vary depending on type of material, size of

workpiece and type of cut that is being performed.

●Characteristics which make blades different are width,

thickness and pitch.

BLADE WIDTH

●Width of blade describes distance from tip of a tooth to

back of blade.

●Width of blade affects rigidity of blade. A wider blade

wanders less and produces a straighter cut.

●Width of blade also limits the smallest radius which can

be cut. A 1/4” wide blade can cut about a 1/2” radius.

BLADE THICKNESS

●Blade thickness describes the distance between sides

of blade. A thicker blade has more rigidity and stronger

teeth.

●A narrow thick blade is used to cut curves while a wide

thin blade is used to make long, straight cuts.

BLADE PITCH

●Pitch describes number of teeth per inch or tooth size. A

blade with more teeth per inch produces a smoother cut.

●The type of material being cut determines number of

teeth that should be in contact with the workpiece.

●For soft materials, the proper blade has between 6 to 8

teeth per inch.

●When cutting hard materials, where shocking is more

detrimental, use a blade with 8 to 12 teeth per inch.

●There should always be at least three teeth in contact

with cut to avoid shocking blade.

●Blade shocking occurs when pitch is too large and blade

tooth encounters too much material. This can strip teeth

from blade.

●Blade manufactures are prepared to supply information

about blades for specic applications.