19

WARNING:

Do not attempt to use this tool until you have fully read and understood all instructions and safety rules contained in

this manual. Failure to comply with these rules and instructions can result in accidents such as fire, electric shock,

or serious personal injury. Save this user’s manual and refer to it frequently for continuing safe operation and to

instruct others who may use this tool.

READ ALL INSTRUCTIONS

•KNOW YOUR POWER TOOL. Read the owner's manual carefully. Learn its applications and limitations as well as the

specific potential hazards related to this tool.

•GUARD AGAINST ELECTRICAL SHOCK by preventing body contact with earthed surfaces. For example: pipes, radiators,

ranges, cookers or refrigerators.

•KEEP WORK AREA CLEAN. Cluttered work areas invite accidents.

•AVOID DANGEROUS ENVIRONMENTS. Do not use the power tool in damp or wet locations or places exposed to rain.

Keep work area well lit.

•KEEP CHILDREN AND VISITORS AWAY. All visitors should wear safety glasses and be kept a safe distance from the

work area. Do not let visitors touch the tool.

•PUT UNUSED TOOLSAWAY. When not in use, tools should be stored in a dry locked-up place, out of children’s reach.

•DO NOT FORCE YOUR TOOL. Your tool will be more efficient and safer when used at the rate for which it was intended.

•USE THE RIGHT TOOL. Do not force small tools to do the job of a heavy-duty tool. Do not use your tool for a purpose

not intended. For example, a circular saw should never be used for cutting tree limbs or logs.

•WEAR PROPER CLOTHES. Do not wear loose clothing or jewellery that can get caught in the tool's moving parts and

cause personal injury. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protective

hair covering to contain long hair and keep it from being drawn into air vents.

•ALWAYS WEAR SAFETY GLASSES. Ordinary eyeglasses have only impact-resistant lenses; they are NOTsafety glasses.

•PROTECT YOUR LUNGS. Wear a face mask or dust mask if the cutting operation generates dust.

•PROTECT YOUR EARS. Wear ear protectors during extended periods of operation of your tool.

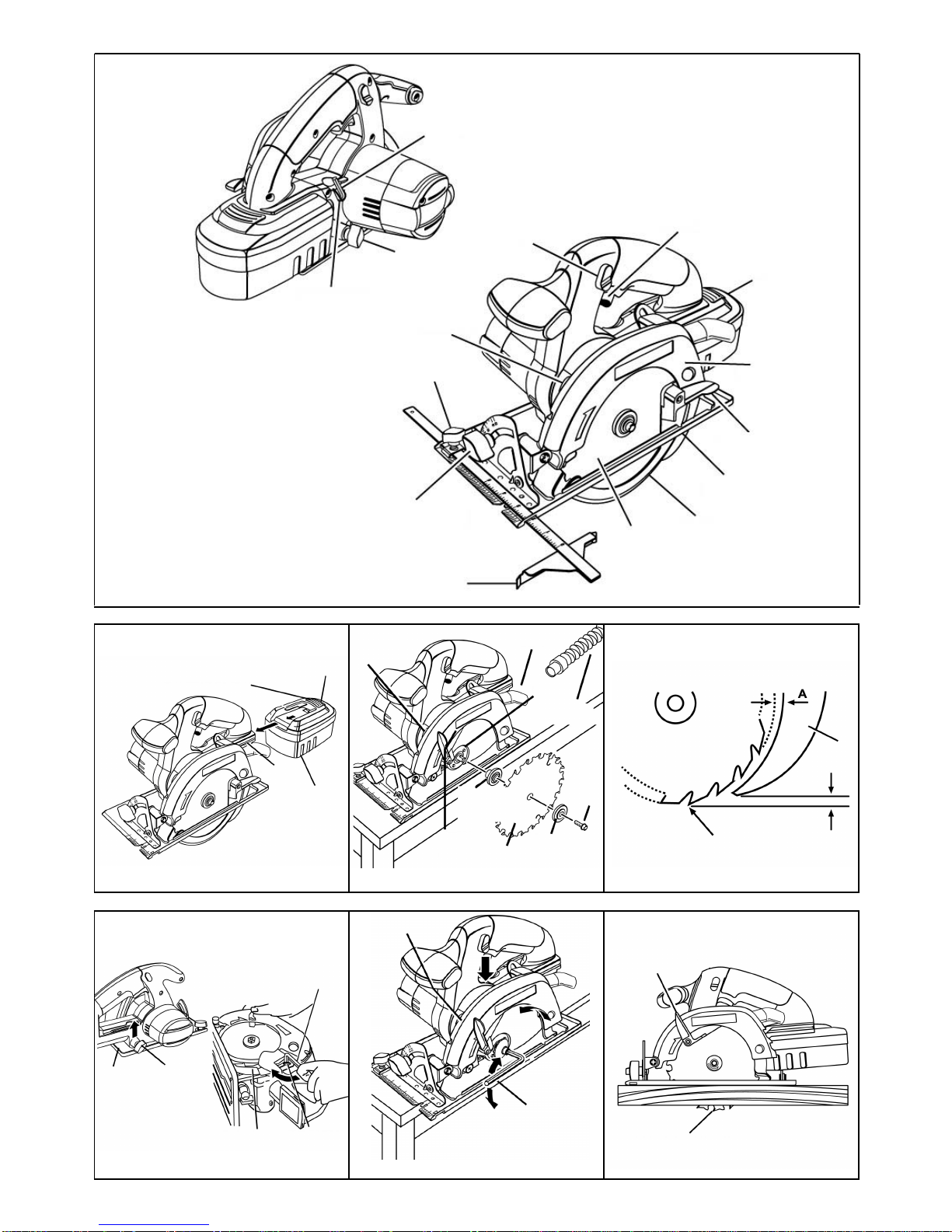

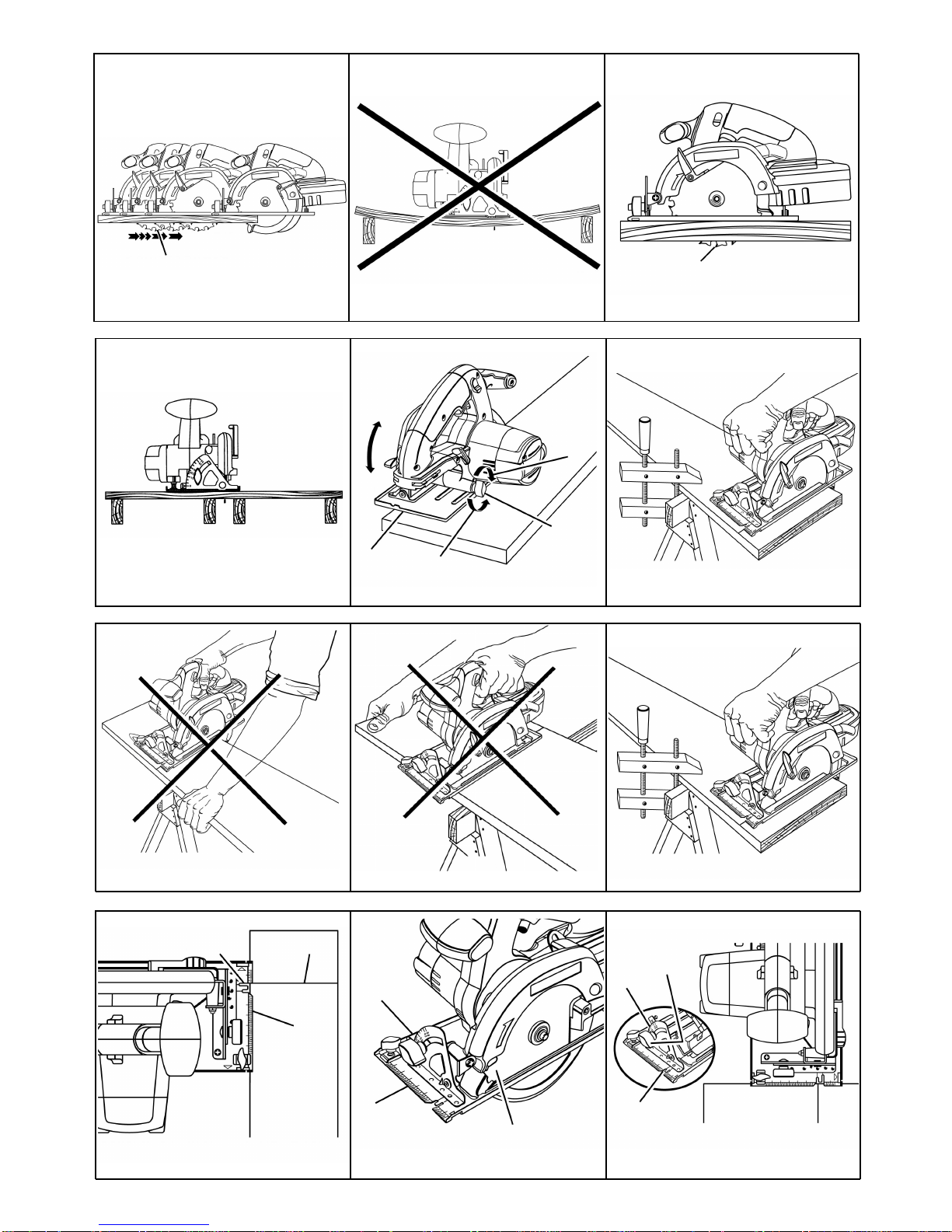

•SECURE YOUR WORKPIECE. Use clamps or a vice to hold down your workpiece. It's safer than using your hand and

it frees both hands to operate the tool.

•KEEP YOUR BALANCE. Keep proper footing and balance at all times. Do not use your tool while standing on a ladder

or any other unstable support.

•MAINTAIN TOOLS IN GOOD WORKING CONDITION. Keep tools sharp at all times, and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

•REMOVE ADJUSTING KEYS AND SPANNERS. Get into the habit of checking that adjusting keys and spanners have

been removed from the machine before turning it on.

•NEVER USE YOUR TOOL IN AN EXPLOSIVE ENVIRONMENT.

Normal sparking of the motor could ignite flammable liquids, gases, or fumes.

•KEEP HANDLES CLEAN AND FREE FROM OIL AND GREASE. Always use a clean cloth to clean your tool. Never

use brake fluid, petroleum-based products or any strong solvents to clean your tool.

•STAY ALERT. Watch what you are doing and use common sense. Do not operate your tool when you are tired. Do not

rush.

•CHECK THAT NO PART OR ACCESSORY IS DAMAGED. Before using your tool, make sure that any damaged part

(the blade guard for instance) will be able to continue working or fulfilling its function. Check the alignment of moving

parts. Check that no part is broken. Check the mounting and any other aspect that may affect tool operation. A guard

or other part that is damaged should be properly repaired or replaced by a RyobiAuthorised Service Centre unless otherwise

indicated in this instruction manual.

•DO NOT USE THE TOOL IF THE SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by

a Ryobi Authorised Service Centre.

•DRUGS, ALCOHOL, MEDICATION. Do not operate your tool while under the influence of drugs or alcohol, or if you

are taking medication.

•CUTTING INTO ELECTRICAL WIRING IN WALLS AND FLOORS CAN CAUSE THE BLADE AND METAL PARTS

TO BECOME LIVE. Do not touch the metal parts when cutting into walls and floors; grasp only the insulated handle(s)

of the tool. Make sure there are no hidden electrical wires, water pipes, or metal framework in the blade path when cutting

into a wall or floor.

•Inspect for and remove all nails from lumber before cutting.

IMPORTANT SAFETY RULES FOR BATTERY-POWERED TOOLS

• Keep in mind that battery-powered tools are always ready to be used since they do not have to be plugged into an electrical

outlet. Be aware of possible hazards when carrying your battery-operated tool, when making adjustments to it, or when

changing accessories.

•USE ONLY THE CHARGER PROVIDED WITH YOUR BATTERY PACK. Do not replace the original charger with any

other charger. The use of another charger could cause batteries to explode and result in serious personal injury.

GB