SAFETY

WARNINGS

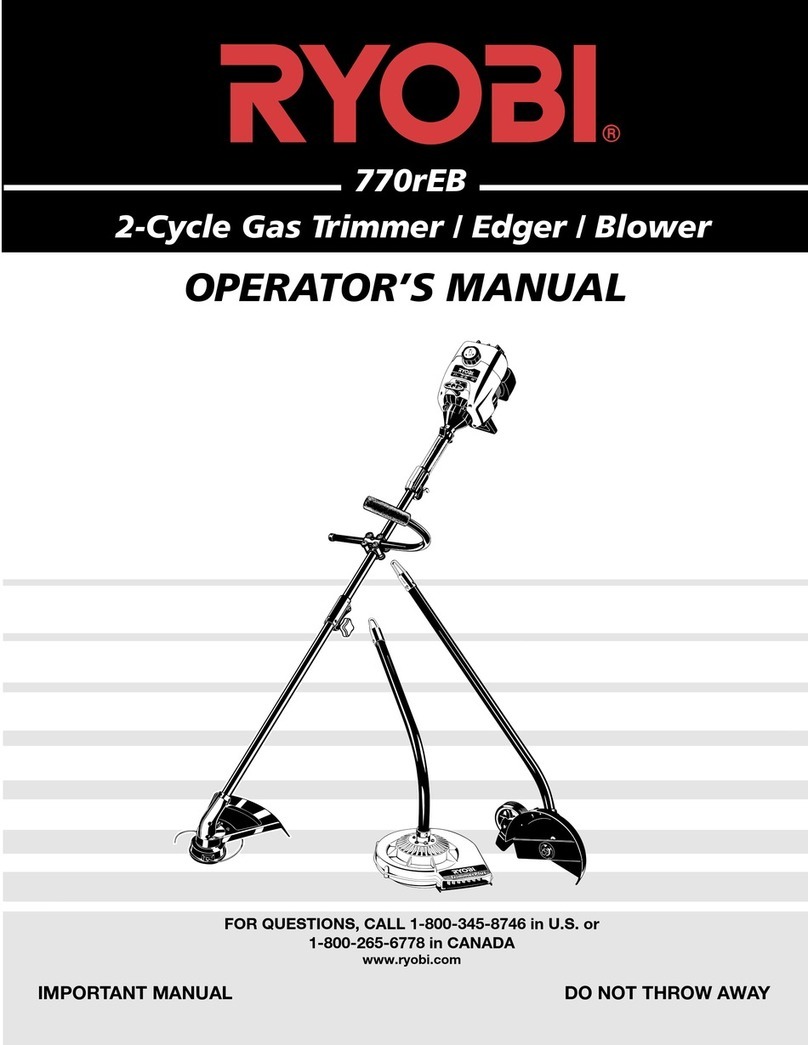

Always holdthe trimmer with both hands when

operating. Keep a firmgrip on boththe front and rear

handles or grips.

FUELING AND PREGOPERATIONAL

Gasoline is extremely flammable and itsvapors can

explode

if

ignited. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the fuel tank. Keepsparks and open flames away

fromthe area.

Store gasoline andfuel only incontainers designed

andapprovedfor the storage of such materials.

Pressure can buildup inthe fuel tank Loosenthefuel

tank cap slowly to relieve any pressure inthe tank

Add fuel in a clean, well-ventilated area. Wipe up any

spilled fuel immediately. Iffuel has beenspilled, allow

it

to dry completely before startingthe engine.

Move the trimmer at least

3

m (10ft) from the fueling

point before startingthe engine.

Thoroughly inspect the trimmer for loose or damaged

parts before each use. Do not use untiladjustments or

repairs are made.

Avoid accidentalstarting. Be inthe starting position

whenever pullingthe starting rope.

Keep all bystanders, especially children, and pets at

least 10m

(33

ft) away fromthe area.

Carefully inspect the areas to becut. Remove all

debris that could become entangled in the string. Also

removeany objects that could bethrown during

cutting.

Before starting. make sure the string head is not in

contact with anything.

DURING OPERATION

Wear safety glasses or goggles at all times when

operating this trimmer.

Dress properly. Do not operate this trimmer when

barefoot or wearing open sandals. Always wear sturdy.

rubber-soledfootwear. The use of gloves, earlhearing

protection and long pants are recommended.

Keep hands, face andfeet away from all moving parts.

Do not attempt to touch or stop the string while

it

is

rotating.

Do not touch the muffler or cylinder. These parts get

extremely hot from operation and remain hot for a short

time after the equipment isturned off.

3

Operate this trimmer only ina well-ventilated area,

outdoors. Carbon monoxide exhaust fumes can be

lethalin a confined area.

If you strike or become entangled with a foreign object.

stop the engine immediately andcheck for damage.

Repairany damage before further operation

is

attempted. Do not operate the trimmer with loose or

damaged parts.

Do not force the cutting headat a rate faster than

ir

is

able to cut effectively.

Usethe right tool. Do not use this trimmer for any job

except that for which it is intended.

Do not overreach. Keep proper footing and balance at

all times.

Always remain alert. To prevent injury to yourself and

others, do not operate this trimmer

if

you are fatigued.

-

Do not operate the engine faster than the speed

necessary to cut, trim or edge. Do not runthe engine at

high speed when not cutting.

Do not extend the trimming line beyond the length

specified inthis manual.

Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

Use only genuine replacement parts when servicing

this trimmer. These parts are available fromyour

authorized service dealer. The use of non-standard

parts, or other accessories or attachments not

designed for this trimmer, could result inserious injury

to the user or damage to the trimmer.

AFTER OPERATION

Storethe trimmer in an appropriate area to prevent

unauthorized use and damage.

Storethe trimmer indoors in a dry location, out of the

reach of children.