11

English(Original instructions)

EN

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

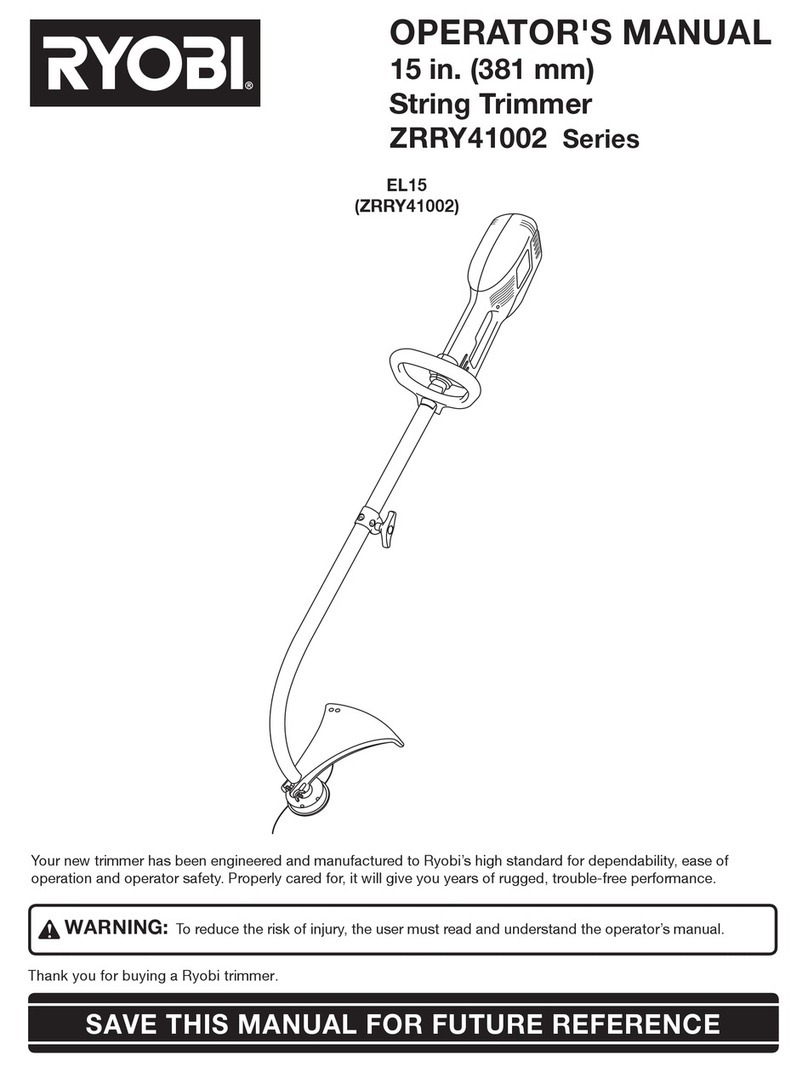

Thank you for buying a Ryobi trimmer.

Your new trimmer has been engineered and manu-

factured to Ryobi’s high standard for dependability, ease

of operation, and operator safety. Properly cared for, it will

give you years of rugged, trouble-free performance.

INTENDED USE

This product should only be used outdoors.

The product is intended for cutting long grass, weed, and

similar vegetation at or about ground level. The cutting

plane should be approximately parallel to the ground

surface. The product should not be used to cut or trim

hedges, bushes or other vegetation where the cutting

plane is not parallel to the ground surface.

WARNING

To reduce the risk of injury, the user must read

and understand the operator’s manual.

WARNING

Do not attempt to operate this trimmer until you

have read thoroughly and understood completely

all instructions, safety rules etc contained in

this manual. Failure to comply may result in

accidents involving fire, electric shock or serious

personal injury. Save operator’s manual and

review frequently for continuing safe operation,

and instructing others who may use this tool.

READ ALL INSTRUCTIONS.

GENERAL SAFETY RULES

Q For safe operation, read and understand all

instructions before using the trimmer. Follow all safety

instructions. Failure to follow all safety instructions

listed below, can result in serious personal injury.

Q Do not allow children or untrained individuals to use

this unit.

Q Never start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

Q Clear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire,

or string which can be thrown or become entangled in

the bump head.

Q Wear full eye and hearing protection while operating

this unit.

Q Wear heavy long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, jewellery of

any kind, or use with bare feet.

Q Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

Q Keep all bystanders, children, and pets at least 15 m

away.

Q Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

Q Do not operate in poor lighting.

Q Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or

exposure to hot surfaces.

Q Keep all parts of your body away from any moving part.

Q Do not touch area around the muffler or cylinder of

the trimmer, these parts get hot from operation.

Q Always stop the engine and remove the spark plug

wire before making any adjustments or repairs except

for carburetor adjustments.

Q Inspect the unit before each use for loose fasteners,

fuel leaks, etc. Replace any damaged parts before use.

Q The string head will rotate during carburetor

adjustments.

Q It has been reported that vibrations from hand-held

tools may contribute to a condition called Raynaud’s

Syndrome in certain individuals. Symptoms may

include tingling, numbness and blanching of the

fingers, usually apparent upon exposure to cold.

Q Hereditary factors, exposure to cold and dampness,

diet, smoking and work practices are all thought to

contribute to the development of these symptoms.

Q It is presently unknown what, if any, vibrations or extent

of exposure may contribute to the condition. There are

measures that can be taken by the operator to possibly

reduce the effects of vibration:

a) Keep your body warm in cold weather. When

operating the unit wear gloves to keep the hands

and wrists warm. It is reported that cold weather is

a major factor contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to increase

blood circulation.

11

SYMBOLS

NAME EXPLANATION

Switch On/Off Switch

I = ON to Run

O = OFF to Stop

Conforms to all regulatory standards in the country in the EU where

the product is purchased.

960401009-03.indd 11960401009-03.indd 11 2010/4/28 4:562010/4/28 4:56