10

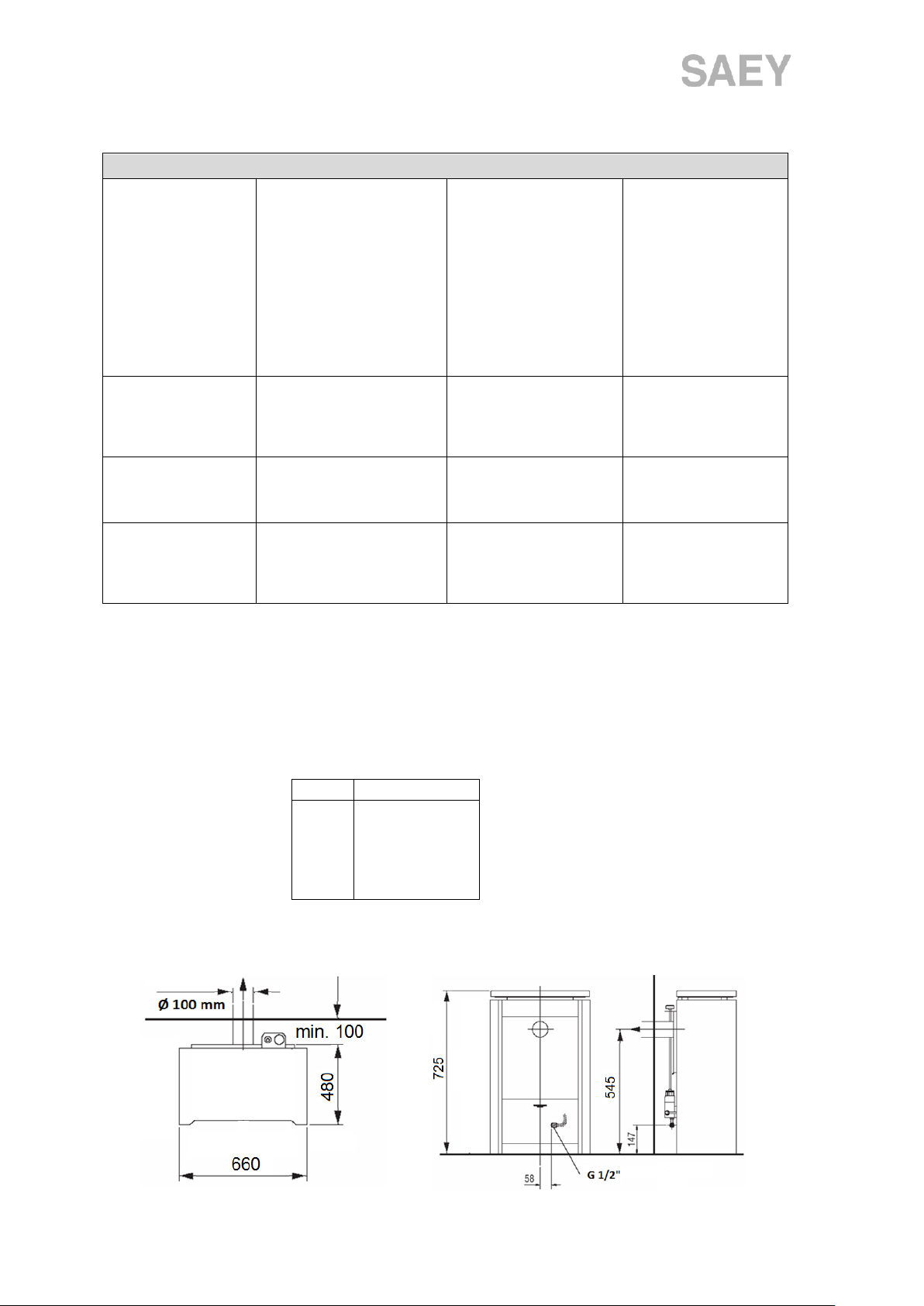

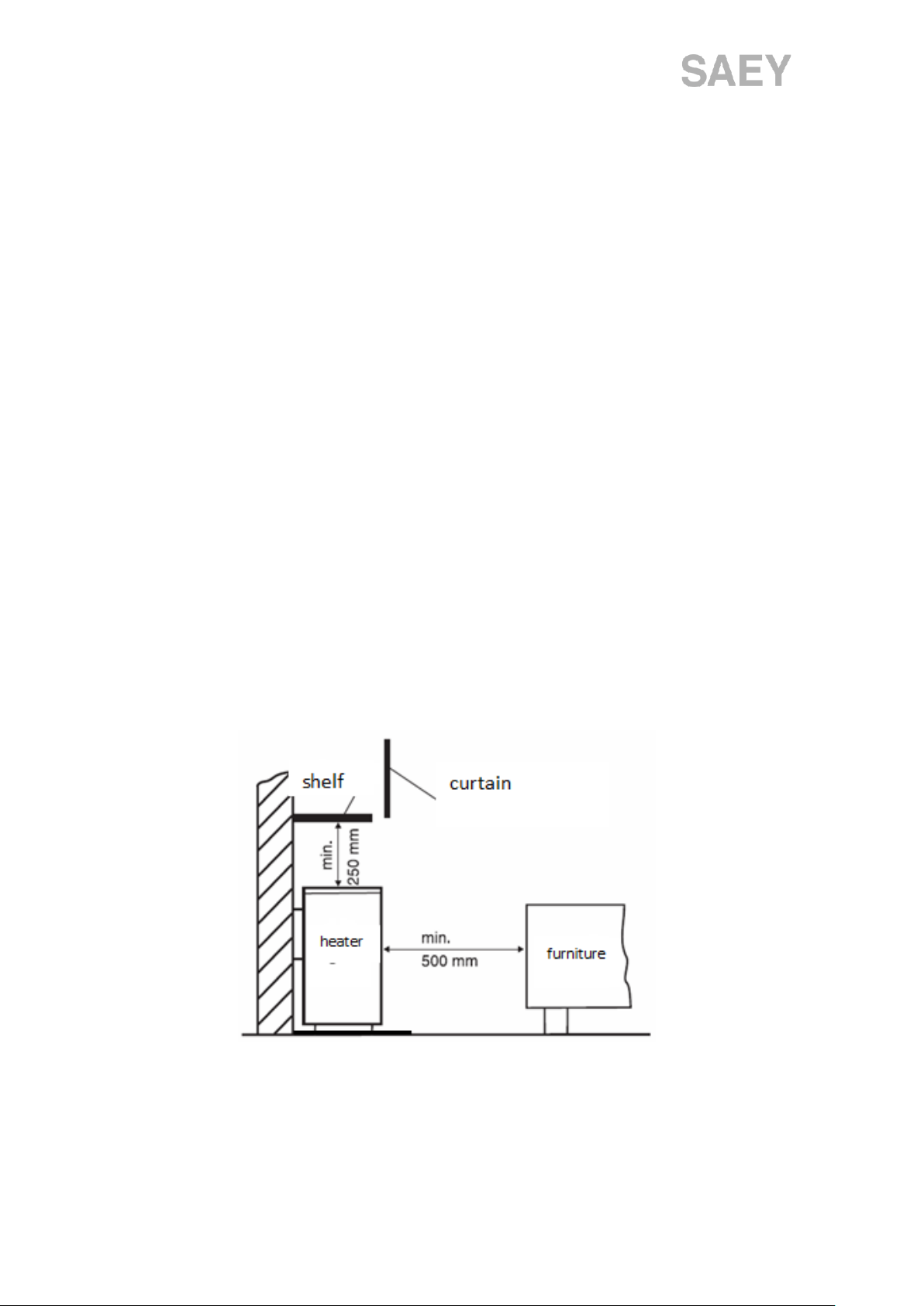

5.1 Placement of appliance

The stove may only be installed on a floor with a sufficient load-bearing capacity. If the floor is not

suitable, measures must be taken to increase the load-bearing capacity. In order to be able to place the

appliance flatly, it is provided with adjustable feet (adjustment screws).

(adjustment screws). If necessary, adjust these so that the appliance is installed as flat as possible.

A gas revision must be carried out for the gas supply to the stove.

Before installation, it is necessary to check whether the type and pressure of the gas in the distribution

network corresponds to the gas opening setting according to the technical data.

The stove may only be operated in a well-ventilated room with sufficient combustion air. Install an air

vent of at least 15cm² that cannot be closed.

If, in the same room and at the same time as the stove, a mechanical ventilation system is in use

(ventilation, tumble dryer, etc.), it must be ensured that sufficient air is supplied and that there is no

underpressure of more than 4 Pa.

The installation of the stove is prohibited in rooms where there is a risk of explosion or flammable

conditions (such as garages).

The thermostat used to detect the temperature in the room is located on the rear wall of the heater.

Poor air circulation in the room or an atmosphere that is too cold may affect the operation of the

thermostat.

The installation must comply with the standards:

- For gas distribution systems EN 1775 - ED. 2, 38 6462 and TPG 704 01

- For installation according to 73 4201 - ED. 2, 06 1008

- Fire classification of construction products and structures EN 13501-1 + A1

Gas connection

- A gas connection must be installed in the same room as the appliance.

- The maximum distance between the connection and the stove is 1.5 m

- Flexible gas pipes may be used if they have been approved for this purpose

- The gas pipe must not be used as a supporting structure.

Recommendations for connection

The stove may only be used for the specified gases:

-Natural gas G20 and G25

-Liquid gas G30 and G31