Doc no: M18 Issue no: 07 Created: 24/08/2009 4

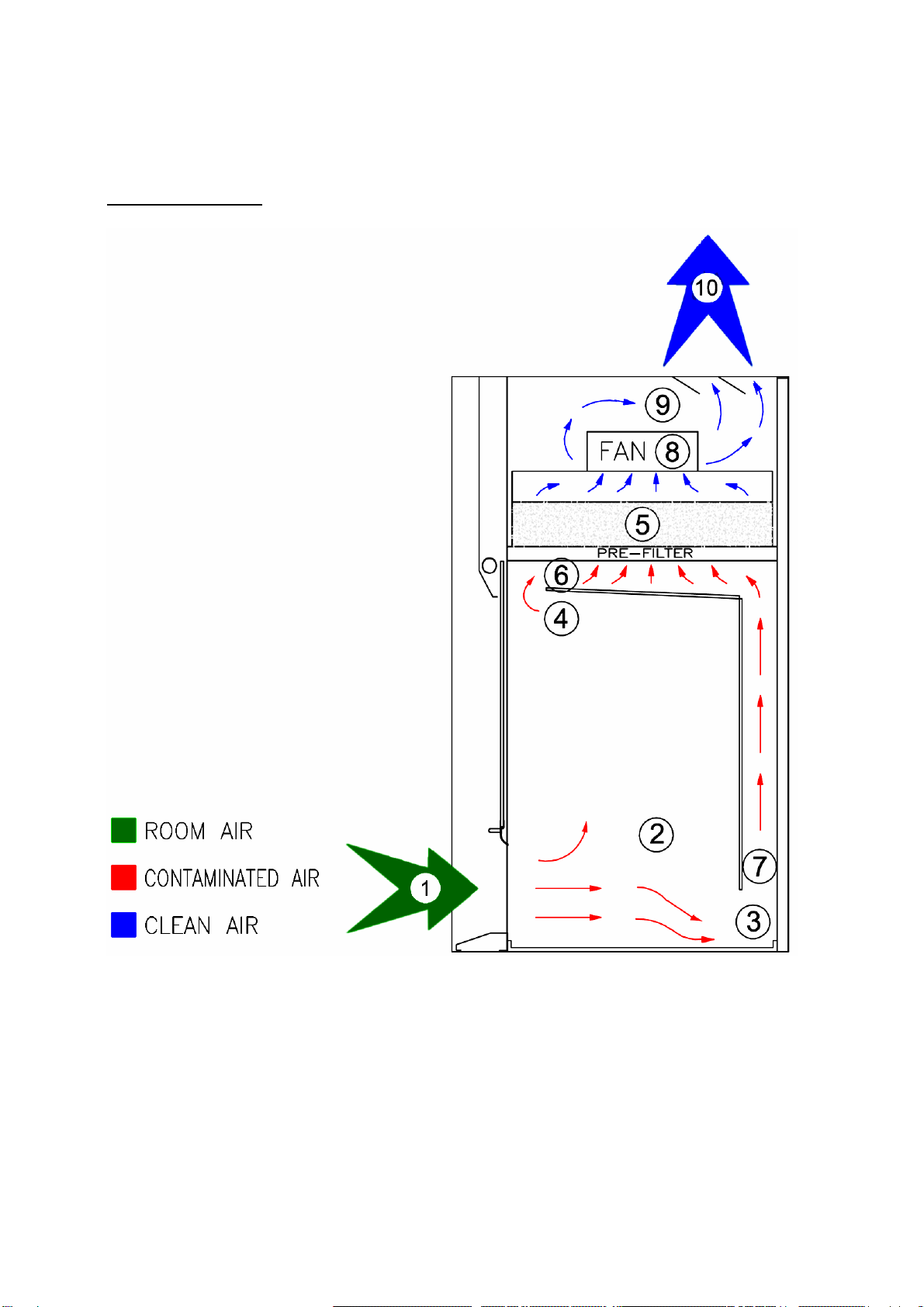

PRINCIPLE OF OPERATION

(1) Recirculatory Mode of Operation (see diagram on following page)

Air is drawn in through the front opening (1) at a velocity ensuring containment of any

contaminants generated within the work area (2).

The operator can determine the required aperture by sliding the glass sash up to a maximum

determined by the sash stop.

The contaminants from area (2) are drawn either upwards as in the case of lighter than air

volatiles (4), or drawn across the worksurface to the secondary extract slot created by the

back baffle, as in the case of heavier than air volatiles or particulates (3).

The combinations of extract slots (6) and (7) ensure that all contaminants entrained in the

airflow are effectively transferred to the filter (5).

The filter(s) (5) combine large surface areas with a deep bed depth to ensure efficient

filtration of contaminants. Clean filtered air is then drawn through the fan(s) (8) and after

passing into the dispersal chamber (9) is exhausted via the louvres (10).

The relatively high pressure drop across the carbon filters ensures even flow through the

filter and exceptionally uniform saturation.

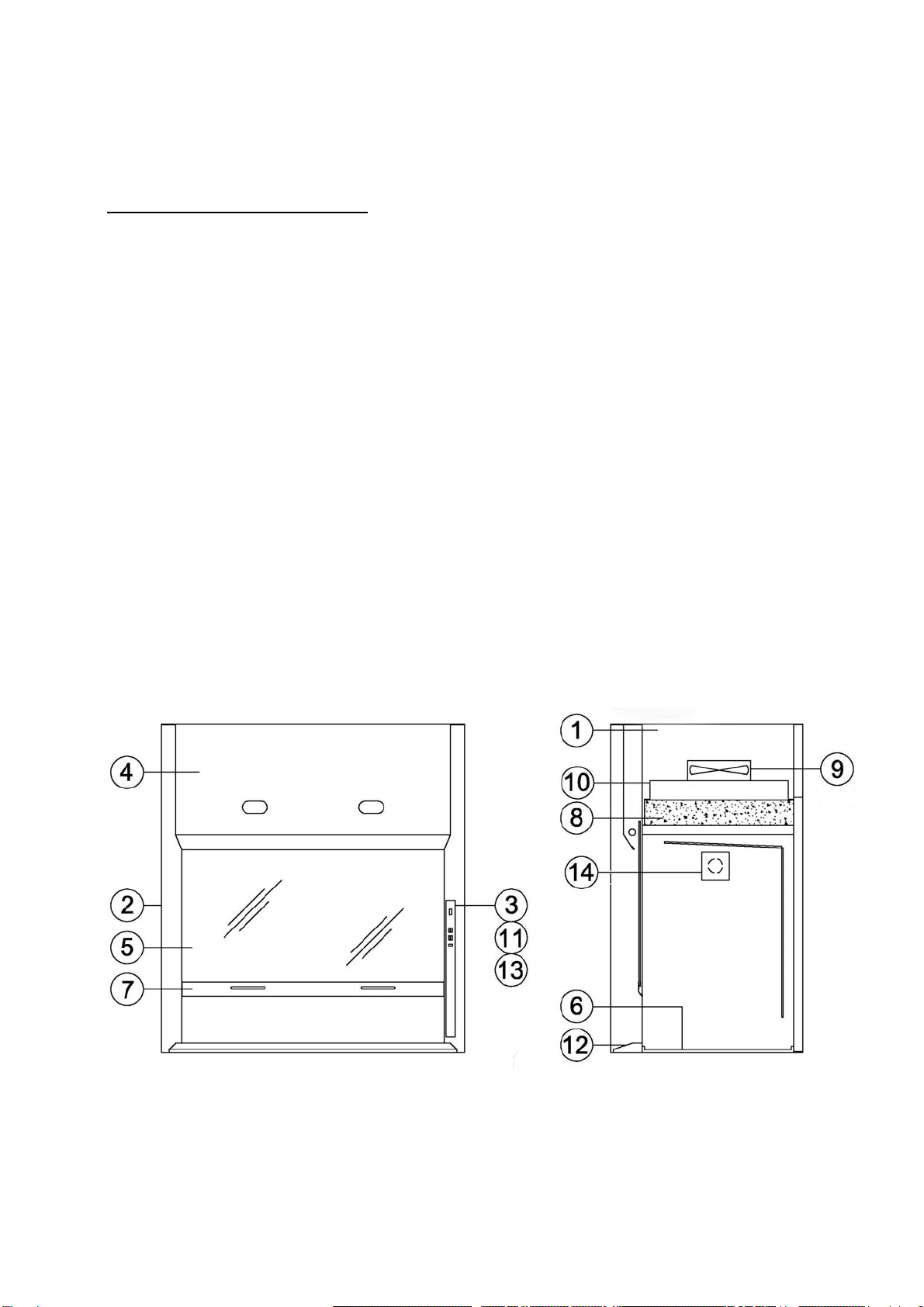

AIRONE™ R Filtration Fume Cupboards present a combination of advantages and unique

features - ensuring the health and safety of operators by prevention of their exposure to

concentrations of toxic chemical compounds providing protection to their environment - in

line with British, European and US Federal Safety Standards.

Moving the vertical gliding safety glass upwards and downwards causes the fan to speed up

or slow down to give a constant face velocity. To avoid the unit alarming unnecessarily, the

sash should be moved slowly.

(2) Ducted - Vented Mode of Operation:

Should venting to outside atmosphere be required after removal of contaminants by efficient

filtration, the duct-work can be connected to the AIRONE Filtration Fume Cupboard via an

optional duct adapter top box fitted with a 250 mm dia. duct outlet and internal transition

adaptors fitted onto the fan(s). This Ducted Filtration Fume Cupboard will also protect

personnel and the environment outside the building - contributing to the overall reduction of

atmospheric pollution.