SAFEGREASE, SAFEOIL

ST-1100i

110i1CEN.doc 16.04.2003 Rev. 1C

CONTROL CENTER ST-1100i

TABLE OF CONTENTS

1 GENERAL DESCRIPTION................................................................................................................................1

2 DESIGN.............................................................................................................................................................1

2.1 Cover...........................................................................................................................................................1

2.1.1 LED-signals..........................................................................................................................................1

2.1.2 Buttons .................................................................................................................................................1

2.2 Control Panel...............................................................................................................................................2

2.2.1 General.................................................................................................................................................2

2.2.2 Display..................................................................................................................................................2

2.2.3 Buttons .................................................................................................................................................2

2.2.4 LED-signals..........................................................................................................................................3

3 OPERATION......................................................................................................................................................4

3.1 Normal mode...............................................................................................................................................4

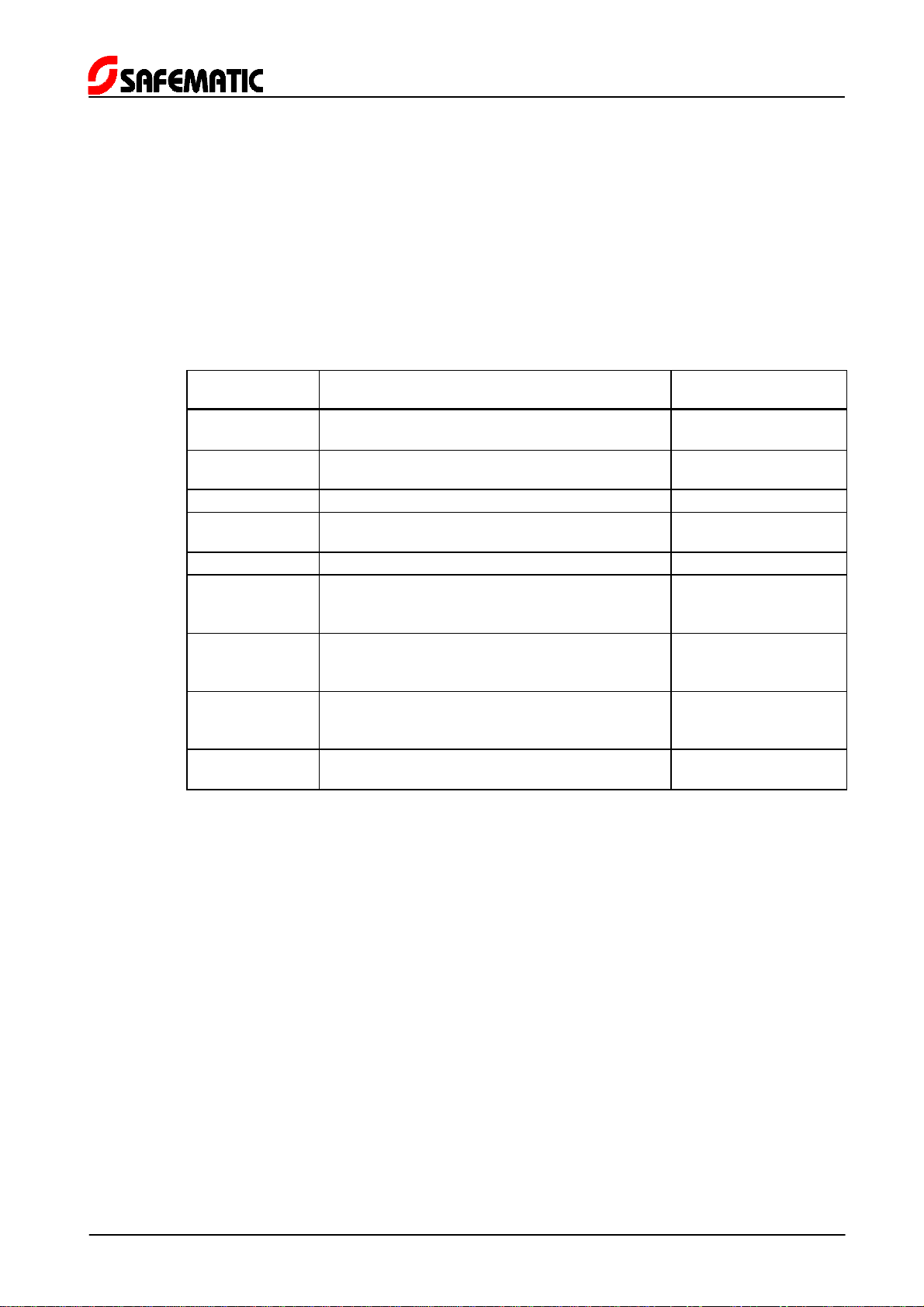

3.1.1 Phase codes for normal mode and alarm mode...................................................................................4

3.1.2 Normal mode displays..........................................................................................................................5

3.1.3 Line pressure displays..........................................................................................................................6

3.1.4 Returning to normal mode....................................................................................................................6

3.2 Extra lubrication...........................................................................................................................................7

3.3 Manual control.............................................................................................................................................7

3.4 Lubrication cycle counter ............................................................................................................................8

3.5 Power failure ...............................................................................................................................................8

3.6 Alarms.........................................................................................................................................................9

3.6.1 Low limit alarm......................................................................................................................................9

3.6.2 Pressure alarm.....................................................................................................................................9

3.6.3 Power failure alarm...............................................................................................................................9

3.6.4 Electronic system error alarm.............................................................................................................10

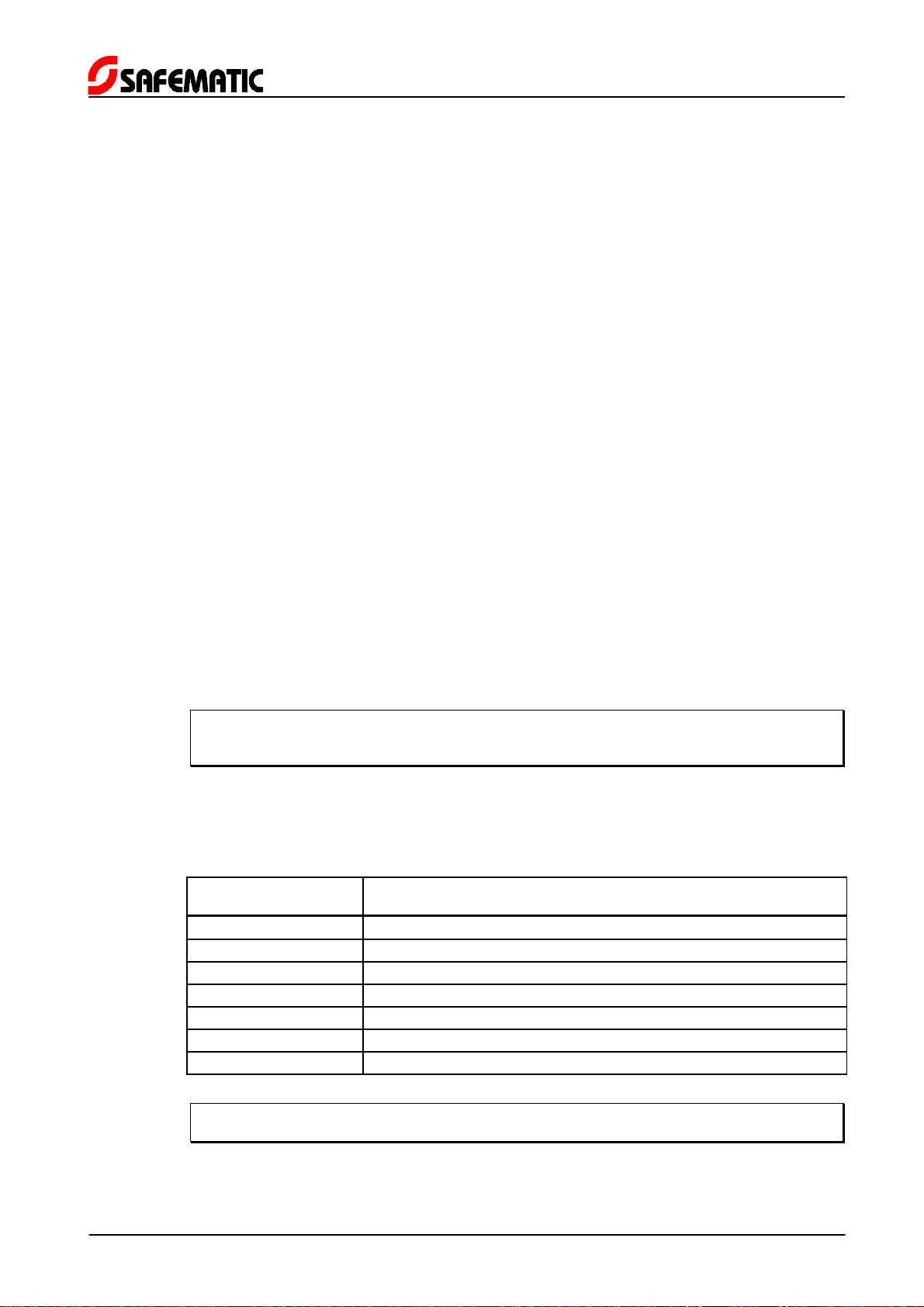

4 SETTINGS.......................................................................................................................................................10

4.1 General......................................................................................................................................................10

4.2 Entering settings........................................................................................................................................10

4.3 Entering password ....................................................................................................................................11

4.4 Setting mode.............................................................................................................................................11

4.4.1 Lubrication cycle counter....................................................................................................................11

4.4.2 Lubrication cycle.................................................................................................................................12

4.4.3 Maximum pressurization time.............................................................................................................12

4.4.4 Pressurization delay time coefficient ..................................................................................................12