ADVICE & INFORMATION:

ØWhen the anchor device is used as part of a fall arrest system, the user shall be equipped with

a means of limiting the maximum dynamic forces exerted on the user during the arrest of a

fall to a maximum of 6kN.

ØThe maximum load that could be transmitted is 150 kg considering a safety factor of 10 as our

Megapod is tested at 21 kN. The direction of loading will always be in vertical.

ØWhen subjected to a load of 0.7 kN for 1 minute performance deformation observed to be '0'.

ØIt is recommended the anchor device is marked with the date of the next or last inspection.

ØFor Stability: Ground level should be plane and webbing should pass through all three legs, In such

position Megapod is designed such that the load acts at the centre of the Megapod and it will

stable.

ØThe anchor device should only be used for personal fall protection equipment and not for lifting

equipment.

WARNING

ØEnsure that the medical condition of the user does not affect his safety in normal and in

emergency cases.

ØThe equipment shall only be used by a person trained and competent in its safe use

ØA rescue plan shall be in place to deal with any emergencies that could arise during work

ØDo not make any alterations or additions to the equipment without the manufacturer prior written

consent, and that any repair shall only be carried out in accordance with manufacturers

procedures

ØThe equipment shall not be used outside its limitation, or for any purpose other than that for which

it is intended

ØAny dangers that may arise by the use of combinations of items of equipment in which the safe

function of any one item is affected by or interferes with the safe function of another

ØEnsure that the harness used confirms to AS/NZS 1891.1 2007 and the Karabiner is connected to

attachment elements of the harness; also ensure that harness has an attachment located

appropriately to the fall arrester.

ØFor equipment intended for use in fall arrest systems, we emphasise that it is essential for safety

that the anchor device or anchor point should always be positioned and the work carried out in

such a way as to minimise both the potential for falls and potential fall distance. Where it is

essential that the anchor device/point is placed above the position of the user, the manufacturer

shall make a statement to that effect

ØA full body harness is the only acceptable body holding device that can be used in a fall arrest

system

ØFor equipment intended for use in fall arrest systems, we emphasise that it is essential for safety

to verify the free space required beneath the user at the workplace before each occasion of use, so

that in case of a fall there will be no collision with the ground or other obstacle in the fall path

Remove all slack from the adjustment chain by loosening the quick connect at the feet of Megapod

legs. Do not use the Megapod if chain is not present. Doing so may result in serious injury or even

death.

INSPECTION : Visually inspect the system before each use to ensure that it is in a serviceable condition

and is operating correctly. If during inspection, doubts are raised about the safety of the system or a

component, these should be replaced either by the manufacturer or a competent person.

COMPATIBILITY : To optimize protection, in some instances it may be necessary to use the Megapod

with suitable boots/gloves/helmet/ear defenders. In this case, before carrying out the risk-related

activity, consult your supplier to ensure that all your protective products are compatible and suitable for

your application.

STORAGE AND TRANSPORT : When not in use, store the Megapod in a well-ventilated area away from

heavily acidic or basic environment. Never place heavy items on top of it. Also ensure that the Megapod

is stored away from chemically hazardous environment preferably storage should be in a dry

environment.

REPAIR : If the product becomes damaged, it will NOT provide the optimum level of protection, and

therefore should be immediately either replaced or repaired. Never use the damaged product. Repair is

permitted, provided that it is either done by the manufacturer or a competent repair centre or individual

approved by the manufacturer.

CLEANING : In case of minor soiling, wipe the Megapod with cotton cloth or a soft brush. Do not use 00

any abrasive material. For intensive cleaning wash the Megapod in water at a temperature between 30 C to 60 C by using a neutral detergent (pH+7). The washing

0

temperature should not exceed 60 C. Do not use acid or basic detergents.

WITHDRAWAL FROM USE : If the system has been used to arrest a fall, it should be removed from service and returned to the manufacturer or a competent repair centre for

servicing and re testing.

Pre- Use Check

Following points must be checked before use:-

ØLocking pins are in its place and are properly

working

ØEnsure that the winch is properly casted

ØRope / Pulley wire must in good condition

ØDetent pins are should be in proper working

condition.

ØEye bolt must not have any cracks

ØTelescopic legs are not damaged

ØMounting brackets are properly installed

Labels

The Megapod is marked with :

(i) Identification of the manufacturer

(ii) Type or product code

(iii) Batch/Lot No

(iv) Year of Manufacture

(v) Size

(vi) Atex marking

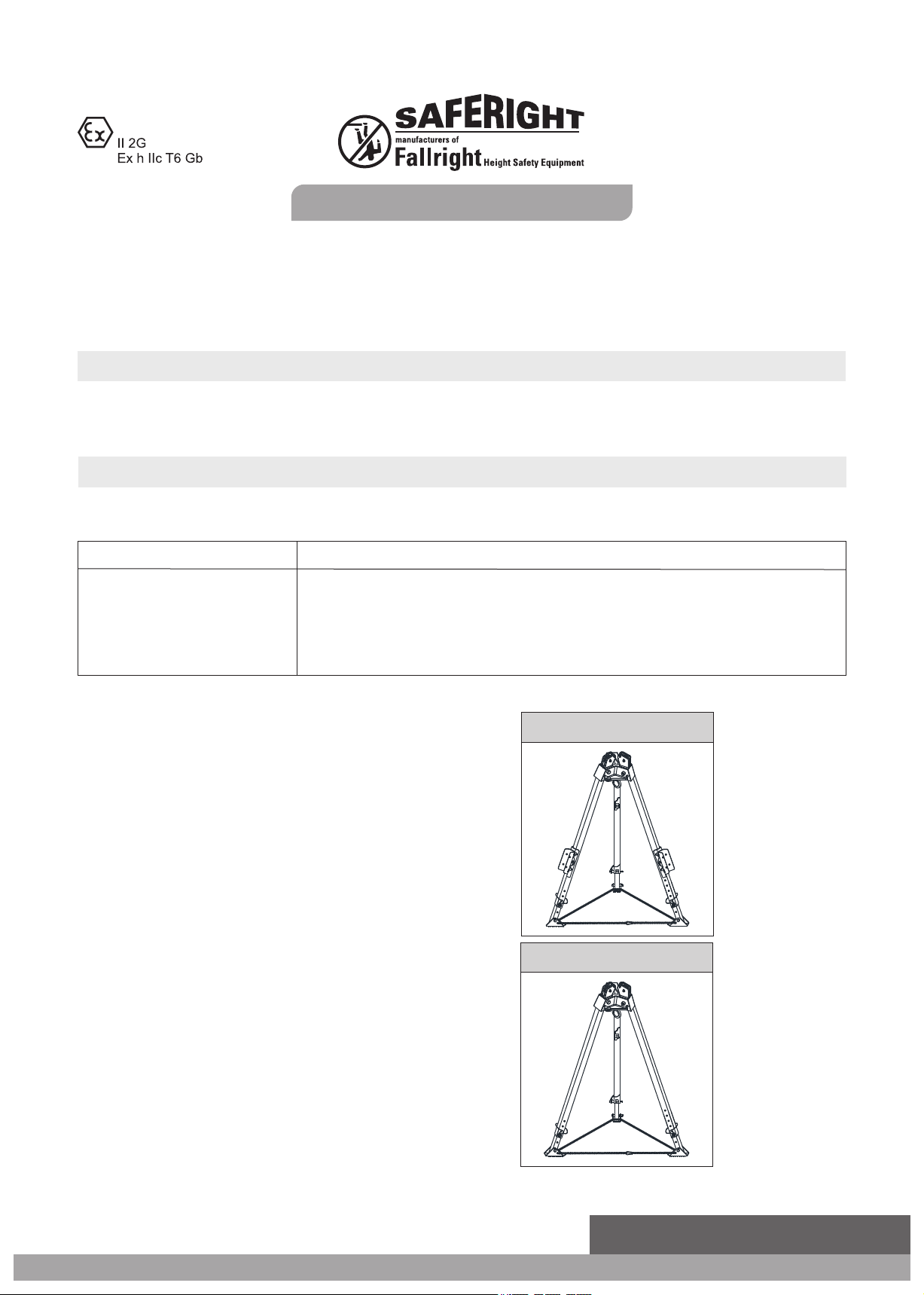

2MEGAPOD

Two Men Suspended Two Men Suspended

Certified to AS/NZS 5532:2013

Issued by BSI

Vide Lic. No.: BMP 709811

Certified to AS/NZS 5532:2013

Issued by BSI

Vide Lic. No.: BMP 709811