3 ERRORS, FAILURES

(Identification of indicators: see wiring diagram)

3.1 NORMAL OPERATION:

The green indicator in the heater’s base flashes

when the heater is on and powered.

The green indicator in the heater’s

base indicates that the flame sensor

has detected a flame in the burner.

A flashing decimal point in the display of the circuit

board indicates that power pulses are sent to the

pump. The convection blower of model 3800 A starts

when the heater power exceeds 3,000 W.

3.2 DISCREPANCIES:

If the green indicator is not blinking during start-up,

it is an indication that the heater is not powered.

If the indicator is not lit after the start-

up process (approx. 6.5 minutes), the

device enters the aftercooling phase

and turns off.

The reason for this could be air in the fuel system. A

new start-up attempt can be made if other problems

are not found.

As the heater is running, if the green flame indicator

dims, the red indicator is lit, fault code 3 shows up on

the display and the heater shuts off, it is usually a

sign of an empty fuel tank or a disruption in the fuel

supply. Check the device for issues.

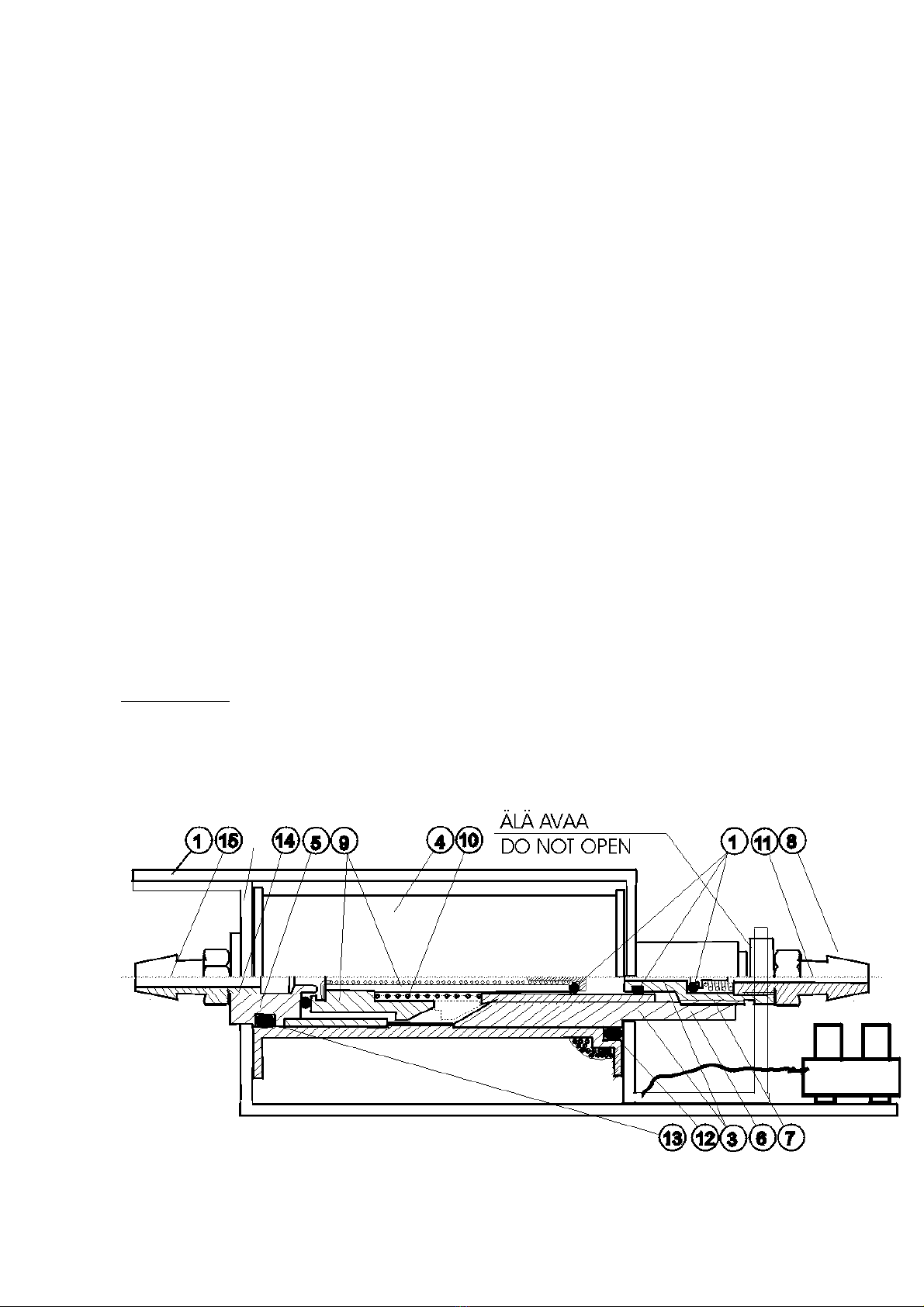

The yellow indicator on the heater’s

base indicates that the input power is

too low (<10.8V, or 10.2V at start-up).

During the start-up process the heater accepts a

lower current. The occurrence of under-voltage

during start-up is usually a sign of too thin or long

power wires to the heater, oxidisation in a connector

or poor connection.

First check the battery status, then the wiring and

connections.

If the under-voltage indicator lights up during use and

the device shuts down, the battery is probably almost

depleted.

If the red indicator is lit, the device

usually shuts down due to a

malfunction indicated by the electronics

(see next chapter).

The most common error is the lack of a flame, which

leads to error code 3 being shown on the display.

Please note! If you have turned off the heater after

the malfunction was shown, you can bring up the error

code again by turning the switch to the AUTO position.

WHEN THE AUTO POSITION IS SELECTED, THE

DISPLAY SHOWS THE LAST ERROR CODE THAT

HAS LED TO THE SHUTTING DOWN OF THE

HEATER.

3.3 ERROR MESSAGES

(in parentheses the text shown on GENIUS screens)

No. 1 (overheat ng fault) indicates overheating.

Overheating is often caused by the heater airways

being blocked, e.g. too tight outlets, or too much fuel,

see page “Inspections”.

No. 2 ( on sat on fault) indicates that the ionisation

electrode is faulty or sooty. The fault also comes up if

the sensor is shorted with the heater frame. The

sensor can be cleaned; see page 8.

No. 3 (combust on fault) indicates that the heater has

stopped due to no flame. This is usually due to the

fuel running out or a blockage in the fuel system.

No. 4 (glow fault) indicates that the glow plug is at

fault: the connector is disconnected, the plug is

broken or its wire is faulty.

No. 5 (combust on fan fault) indicates that there is a

fault in the combustion air fan or its wiring.

No. 5 (convect on fan fault) indicates that there is a

fault in the main fan or its wiring.

No. 7 (undervoltage fault) indicates undervoltage. See

section about indicator lights on the heater.

No. 8 (pump fault) indicates that the circuit of the

pump is not closed.

The letter b (number 11 in SMS’es) indicates that the

overflow sensor has detected oil in the collection

space under the circuit board. It must be cleaned and

the fault must def n tely be repaired before the next

start-up.

The dec mal on the fault d splay blinks with the pulses

of the pump.

The pump is not powered if the decimal does not

blink and the pump does not make a clicking sound.

The fault is either in the wiring of the pump, the coil or

the circuit board.

If the decimal blinks while the pump does not make a

clicking sound, and the wires are not in a short circuit,

the pump is faulty; usually due to fuel thickening or

impurities in the fuel.

+ -