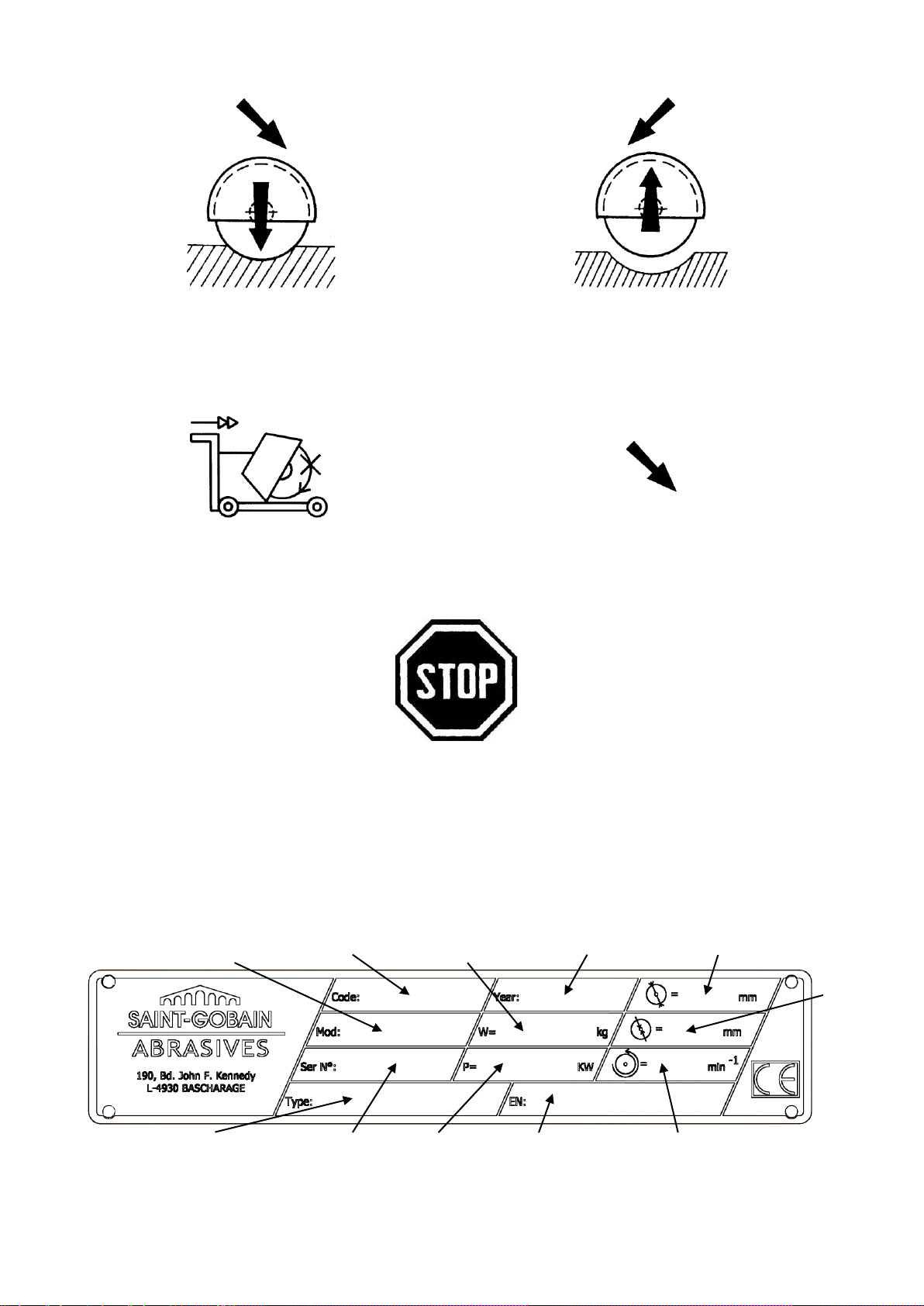

VERS.2017.06.12 C51_MAN_EN

10

Made of jig welded open profile steel, the C51 is stable but at the same time, easily

transportable.

The one-piece blade guard (1) fully protects the operator and his working environment. It is

firmly fixed to the main frame. A handle on the top of the blade guard facilitates its removal

when changing blades.

A manually operated hand wheel mechanism (2) enables graduated depth setting. Turning the

hand wheel clock- or anti-clockwise will raise or lower the cutting blade.

The handle (3) is detachable or can be reversed for easy transportation. The height is

adjustable.

The motor frame (4), supporting the blade shaft, the motor, the blade guard and the belt guard,

is articulated on the rear axle.

The precisely manufactured blade shaft is fitted into two heavy-duty self-aligning pillow block

bearings, including grease nipples. The shaft is 30mm in diameter. A three-belt taper lock pulley

is fitted on one end. The shaft is reduced to 25,4mm at the other end, allowing an inner flange

complete with dowel pinholes to be fixed.

The steel belt guard (5) is a sealed two piece unit. The backing plate is bolted to the mainframe

of the machine and two locking nuts are welded to it. The outer guard, covering the three drive

belts and taper lock pulleys, is held in place by two locking bolts.

The pointer (6) allows the operator to make precise cut easily.

The water tank (7), with a capacity of 20 litres, can be easily removed from the machine,

allowing the tank to be refilled without having to move the machine.

The machine has a GX200 Honda engine (9), with 6,5HP. An emergency shut down switch (8)

near the levers allows an immediate stop of the machine in case of danger.