-5-

(2)Openthemainneedle2turnsfromthatstateandusethethrottlesticktofullyopenthethrottlevalve.Ifrichair-fuelmixture

canʼtbeobtained,openthemainneedleadditionally.Thencontinuerunningformorethan1tank.Duringthisinitial

operation,contactofeachpartinsidetheenginewillbematched.Somakethefuelmixturerichasmuchastheengine

doesnʼtstop.Donotcareaboutrunningsmoothnessatthisstep.

(3)Refillthetankandruntheenginewiththemainneedletoachievepeakandlessspeed(richer)alternatelyabout5times.

Andthenmaintainthepeakconditionlonggradually.Whenitgetsstable,thenoperatethethrottlesticktovaryslowspeed

tohighspeedseveraltimestochecktheresponse.Afterthatrunitfor1tankkeepinghighspeed.

(4)Whenitcomestorunsmoothlyatpeak,break-inonthegroundiscompleted.Thenperformtappetadjustingreferringto

Chapter14andadjustthecarburetorreferringtoChapter13.Afterthat,flyitforabout20timesinrichconditiontofinish

break-inintheair.

Alsoafterbreak-in,pleaseruntheengineinrichconditionaslongasitdoesnʼtaffecttotheflight.

13.Adjustmentofcarburetor

Sinceagas-enginehasnarrowrangeofair-fuelratio,adjustmentoftheneedlesisstricterthanaglow-engine.Andboth

needlesareinterferedslightlyfromeachothersoconfirmthebalanceofpeakandresponseafteradjustment.

Inprinciple,thecarburetorshouldfirstachievepeakbyadjustingthemainneedle.Thenperformingidlingwiththethrottle

valveandtheslowneedle.(Unlessthepeakiscertainlyachieved,idleadjustmentwillbedifficultandnotstabilized.)

*Theslowneedleissetastokeeparound1,500~1,800rpmatidlingatfactorydefault.

(1)Afterfillingupthefueltank,starttheengineasdescribedinChapter11andrunitfor1minutesinrichcondition.Thenfully

openthethrottlevalvewiththethrottlestick.

(2)Byturningthemainneedlewiththeadjustmentbarobservingtachometerandexhaustsound,achievepeakcarefully.

(3)Next,closethethrottlevalveuntiltheenginerunsstablywithanidlingrotationaround1,500rpmbyadjustingtheslow

needlewiththeadjustmentbarcarefully.(Duringflight,itʼsratherstablewithslightlyhighadjustedatidling.)

*Thebestrichnessoftheair-fuelmixtureatslowspeedisdependontheflightstyle.Generally,Scaleflightrequiresstabilityin

lowspeedsoslightlyleanconditionispreferable.OntheotherhandAcrobaticflightrequiresquickresponsefromlow

throughhigh,soslightlyrichconditionispreferable.

(4)Oncetheidlingisset,getthethrottlevalvefullyopenedgradually.Iftherevolutionbecomessloworgoesupsuddenly,

adjusttheslowneedlecarefullyuntilrpmraiseslinearlyfromidlingtopeakbyfine-tuning.

(5)Afteradjustmentof(4)iscompleted,performtheprocessfromidlingtopeakquickly.Ifrevolutiongetsdelayedtoachieve

peakevenifthethrottlevalveisfullyopened,fine-tunethemainneedleandperformthesameprocess.Repeatthis

fine-tuneandresponsecheckcarefullyuntiltheresponseimproves.

Atipforcarbadjustmentistosettheslowneedleslightlyleanaslongastheenginedoesnʼtstopwhenopenthethrottle

valvequicklyfromlowtohigh.

Forthemainneedle,richconditionasfarasitdoesnʼtaffecttotheflightisaknacktoincreasetheenginelife.

Thebesttunevariesdependingonmanyfactorssuchasweather,qualityoftheoil,prop,andsoon.

Duringyourflights,pleaseperformfine-tunesothatlow-middle-highspeedmatchesbestwiththeairplane.

Note:Duringearlystageofflights,taketheheighthighenoughtolandsafelyincasetheenginestopintheairsuddenly.It

willreducetheriskofcrashorlandingaccident.

Caution:Toomuchthrottlingthemainneedleisverydangerousbecauseitmightcauseknockingandthepropnutmightbecame

off.Onceyounoticeabnormalvibrationorsoundduringthrottlingthemainneedle,justreturntoopentheneedleimmidiately.

14.Normaloperation,maintenance,andadditionalinformation

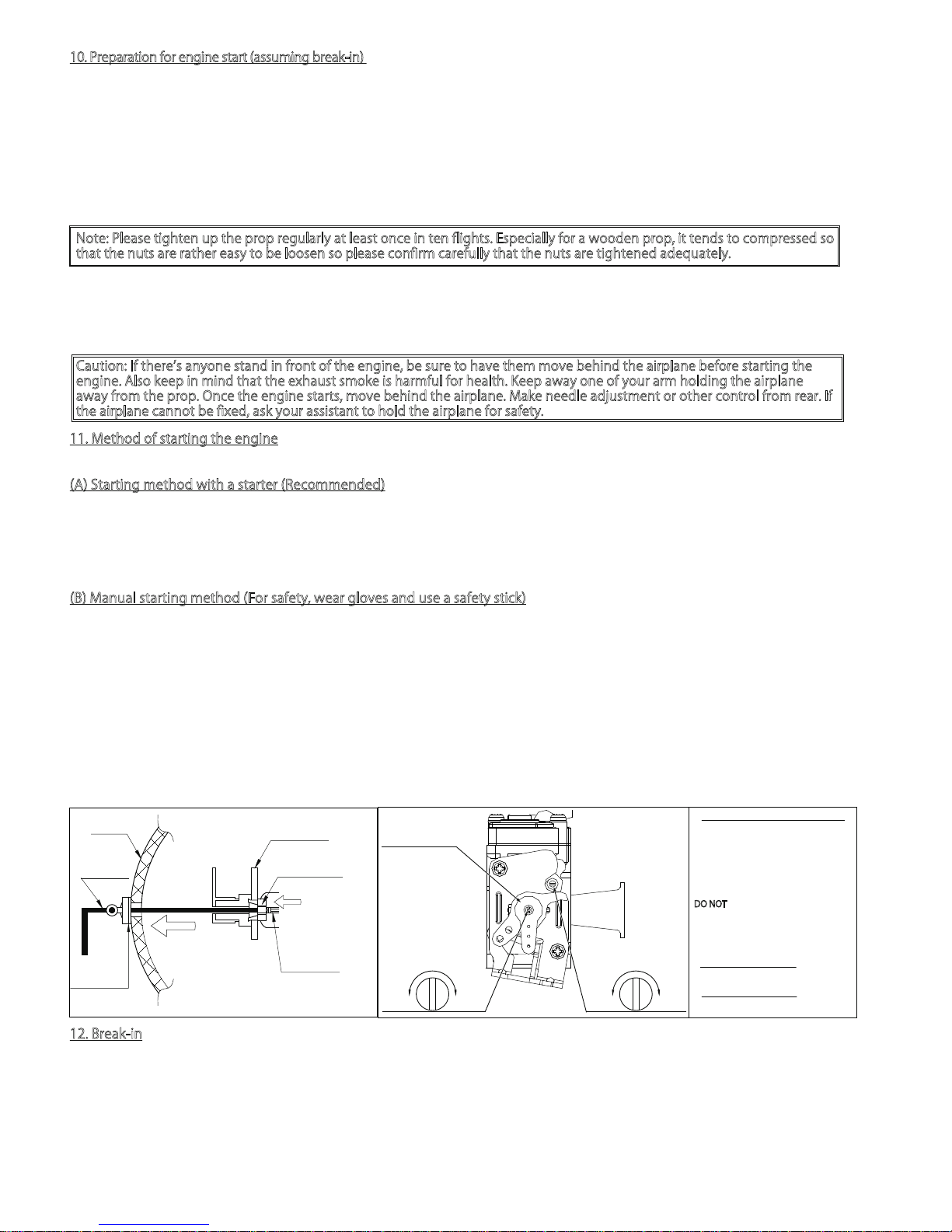

(1)Aftercompletinggroundbreak-inoroperatingtheenginefor1hour,adjusttappetgaps(valveclearances)byfollowing

proceduretocompensateinitialwearing,whiletheengineiscold(Fig.10).Toperformitfirst,eithercylinderisOK.

(a)Removetheplugandrockercoversfromthecylinder.

(b)Turnthepropslowlyforwardbyhanduntiltherockerarmofintakestops.Furtherturntheproptobringthepistonto

theTDC(TopDeadCenter)ofcompressionstroke.

(c)Usetheattachedwrenchandhexagonalwrenchtoadjustthegapsindefi-

nitelyclosetozerowithintherangecompressionexists.Ifthegapislower

than0,thevalvehastobeopenedatallphasessothecompression

doesnʼtoccur(then,loosenthescrewtoreset).

Afteradjustment,putonthesparkplugandturnthepropforwardtocheck

ifthecompressionisenough.

(d)Oncheckingthegap,securelytighten(butnotexcessively)thelocknut.

(e)Dothesameadjustmentfortheothercylinder.

*Inthecaseoftheenginesforvehicle,smallgapisgiventotappetstoabsorb

valveelongation.HoweverforSAITOengines,gapbecomeslargerduringoperationsduetothermalexpansionofthecylinder

(madeofaluminum).Thereforesetthegapindefinitelyclosetozerowhentheengineiscold.

(2)Justafterstartuptheengine,performwarmuprunninginrichconditionforabout1minute,andjustbeforestoprunitat

idlingfor1minutetocooldownaswell.

(3)Whenstoptheengineafterthefinalflightoftheday,besuretostopbycuttingthefueltoremovefuelfromthecarburetor.

Andremovethefuelfromthetankandreserveitwithspecialcare.

(4)Sincethefuelcontainsmorethan5%ofoil,sometimestheexhaustvalvegetsdullbycarbonorsludgeespeciallyincold

atmosphere.Thenturnofftheignitionswitchandrotatethepropbyelectricstarter.Afterdilutetheoilcontentbythisway,

removethefuelfrominsidethecarbandtheengine.Ithelpsthevalvetomovesmoothly.

Or,removetherockercoverandapplyingsomeanti-rustspraytotheexhaustvalveiseffectiveaswell.

Tappetadjustment

Fig.10