3.Break-inMOSTIMPORTANT!!

●Prop-recommendation:APC-24”x12”forbreakin.

●Use15:1fuel:oilratioforbreakin.

●Nevermakethefuelmixtureleanduringbreakin.

Itcouldcauseseizureevenduringidlingorlow-speedrunning.

●Beforestartingtheengine,openthemainneedleApprox.3turns

andtheslowneedleApprox.5turnsCCWeachfromfullclose.

●Starttheengine(usingastarterisrecommendedforsafety).

●Runforabout5secondsatlowspeedtowarmup.

●Openthrottlegraduallyuptooverhalfopen,inthemeantimeturnthe

mainneedleCCW.ContinuetoturnthemainneedleCCWuntiltheRPM

declines,keepingthethrottleopenedoverhalf.

●ThenturntheslowneedleCCWtomakemixturemuchricher.

●Runinthisveryrichconditionfor2tanks.

Note:

●Asthefuelcontainsoil,theexhaustwillproducesomeresidueontheairplane.

●Usereliableandwellbalancedprop,otherwiseitcancauseabnormalvibrationandmayresultinseriousaccident.

●Duringoperation,thescrewsallovertheenginecanbeloosenbyheatexpansionofmetal.Tightenthemup

occasionally.

●Whentheexhaustvalvegetsdullbycarbonorsludgeespeciallyincoldatmosphere,removetherockercover

andapplysomeanti-rustspraytotheexhaustvalvetohelpthevalvetomovesmoothly.

●Allresponsibilitiesfortheuseoftheengine,andotherobligationsandresponsibilitiesbasedonlaws,regula-

tions,etc.arebornebythepurchaserandtheuser,andSAITOSEISAKUSHOCO.,LTD.isexemptfromany

responsibilities.

Warranty:

●Ifthereisanydeficiencyfromthefactoryconcerningmanufacture,pleaseconsulttheshopordistributoryou

purchasedfrom,sothatourcompanywillrepairthemwithresponsibility.Anyfailureortroublecausedby

unnecessarydisassembly,modification,orotherusesthanthoseprovidedintheinstructionmanualisnot

subjecttothewarranty.

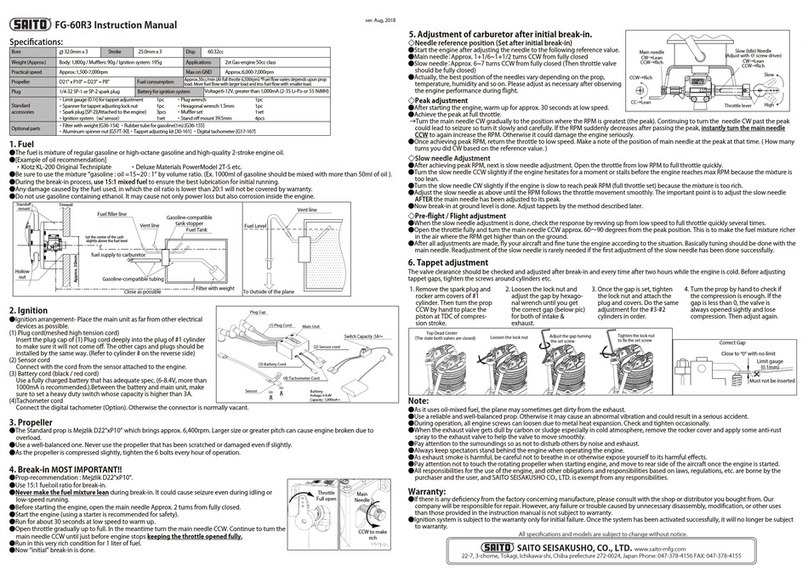

Φ37.2mm 27.6mm 89.99cc

D24”~25”xP10”xP12”

・Filterwithweight[G36-154] ・DurabletubeforGasoline(1m)[G36-155]

・Aluminumspinnernut[57T-30] ・Tappetadjustingkit[120S-161] ・Digitaltachometer[G17-167]

Bore

Mainbody:3,161g/Muffler:157g/Ignition:250g

Stroke Disp.

Weight(Approx.) RPMRange Approx.1,300-7,000rpm Maxonground Approx.6,000-6,500rpm

Propeller CM-6Plug

Optionalparts

Gasoline60-70㏄classApplications

Batteryforignitionsystem Voltage:6-12V,greaterthan1,000mA(2-3SLi-Poor5SNiMH)

・Limitgauge(0.1t)fortappetadjustment1pc ・Spannerfortappetadjustinglocknut1pc ・Carburetoradjustmentbar1pc

・Sparkplug[CM-6](Attachedtotheengine)3pcs ・Mufflerset 1set・Chokebar 1pc

・Ignitionsystem(w/sensor) 1set ・Mufflerbracket 1set・Plugwrench 1pc

・Standoffmount1set ・Anti-looseningnut 1pc ・Hexagonalwrench 1set

Specifications

FG-90R3InstructionManual

4.Needlereferenceposition(SetAfterBreak-in)

●Mainneedle:Approx.2.5~3turnsfromfullyclose

●Slowneedle:Approx.4-1/2~5turnsfromfullyclose(Thenthrottleshouldbefullyclosed)

●Actuallythebestconditionoftheneedlevariesdependingontheprop,temperature,humidityandso

on.Pleaseadjustbasedontheengineperformanceduringflight.

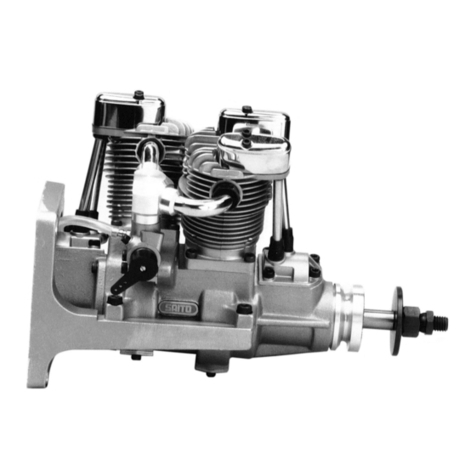

5.Tappetadjustment

ThevalveclearanceshouldbecheckedandadjustedafterBreak-inandeveryafter2hourswhilethe

engineiscold.Beforeadjustingtappetgaps,tightenthescrewsaroundcylindersetc.

1.Removethesparkplug

androckerarmcoversof

#1cylinder.Thenturnthe

propCCWbyhandto

placethepistonatTDCof

compressionstroke.

2.Loosenthelocknutand

adjustthegapbyhexago-

nalwrenchuntilyouget

thecorrectgap(below

pic)forbothofintake&

exhaust.

3.Oncethegapisset,

tightenthelocknutand

attachtheplugand

covers.Dothesame

adjustmentforthe#3-#2

cylindersinorder.

4.Turnthepropbyhandto

checkifthecompression

isenough.Ifthegapisless

than0,thevalveisalways

openedsightlyandlose

compression.Thenadjust

again.

CorrectGap

Mustnotbeinserted

Closeto“0”withnolimit

Limitgauge

(0.1mm)

2.Ignition

●Ignitionarrangement-Placethemainunitasfarfromotherelectricaldevicesaspossible.

(1)Plugcord(meshedhightensioncord)

Inserttheplugcapof(1)Plugcorddeeplyintotheplugof

#1cylindertomakesureitwillnotcomeoff.Theother

capsandplugsshouldbeinstalledbythesameway.

(Refertocylinder#onthereverseside)

(2)Sensorcord

Connectwiththecordfromthesensorattachedtothe

engine.

(3)Batterycord(black/redcord)

Useafullychargedbatterythathasadequatespec.(6-12V,

morethan1000mAisrecommended.).Betweenthe

batteryandmainunit,makesuretosetaheavyduty

switchwhosecapacityishigherthan3A.

(4)Tachometercord

Connectthedigitaltachometer(Option).Otherwisetheconnectorisnormallyvacant.

ForCCW

Makerich Main

needle

ForCW

Open

Throttle

lever

Slowneedle

CCW

Rich

CW

Lean

Mainneedle

Throttle

lever

Standard

accessories

FuelTank FuelLevel

ToOutsideoftheplane

Ventline

fuelsupplytocarburetor

Fuelfillerline

Ventline

Gasoline-compatible

tankstopper

Gasoline-compatibletubing

Filterwithweight

Setthecenterofthecarb

slightlyabovethefuellevel

Closeaspossible

Firewall

Standoffasrequired

Hollowoutreferringto

thecuttingsheet

PlugCap

SwitchCapacity:3A〜

Sensor

(2)Sensorcord

Battery

Voltage:6-12V

Capacity:1,000mA〜:

(

1)PlugCord MainUnit

(3)BatteryCord

(4)TachometerCord

Loosenthelocknut

Adjustthegapturning

thesetscrew

TopDeadCenter

(Thestatebothvalvesareclosed) Tightenthelocknut

tofixthesetscrew

3.Methodofchoke(Noneedwhenyouusestarter)

●Inadvance,makeathinholeonthecowlingtoinsertthechokebar/

slowneedleadjustmentbar.

●Duringchoking,besuretoturnofftheswitchoftheignitionsystem.

●Asshowninthefig,passthechokebar(withM3.5threadonitstip)

throughtheholeonthecowling.Thenturnthebartoinsertintothe

M3.5internalthreadatthecenterofthethrottlelever.

●Fullyclosethethrottleandpullthechokebarandfixitwithaclipor

clampasshowninthefigsothatitmaynotgobacktotheprevious

position.

●Graspthepropbyhandandturnitinthedirectionofnormaloperation

(CCW)forseveraltimes,untilthecarburetorgenerateshissing-like

sound.Afterhearingthissoundforabout5times,quicklyflicktheprop

approximately10times.

●Afterthat,removethechokebar.Afterthat,powerontheignitionsystemandflickthepropquicklytostarttheengine.

Iftheenginedoesnʼtstart,repeatthechokingprocedure.

Cowling

chokebarforinsert

M3.5screw

Throttlelever

Throttlevalve

(Movetotheleft)

Slowneedle

chokebar

Temporaryfixed

byaclip

1.Fuel

●Thefuelismixtureofregulargasolineandhigh-quality2-strokeengineoil.

●[Exampleofoilrecommendation]

・KlotzKL-200OriginalTechniplate ・DeluxeMaterialsPowerModel2T-Setc.

●Besuretousethemixture“gasoline:oil=15~20:1”byvolumeratio.(Ex.1000mlofgasolineshouldbemixed

withmorethan50mlofoil).

●Duringthebreakinprocess,use15:1mixedfueltoensurethebestlubricationforinitialrunning.

●Anydamagecausedbythefuelused,inwhichtheoilratioislowerthan20:1ratio,isnotwarranted.

●Donotusegasolinecontainingethanol.Itmaycausenotonlypowerlossbutalsocorrosioninsidetheengine.

SAITOSEISAKUSHO,CO.,LTD.www.saito-mfg.com

22-7,3-chome,Tokagi,Ichikawa-shi,Chibaprefecture272-0024,JapanPhone:047-378-4156FAX:047-378-4155

FG-19R3InstructionManual

Allspecificationsandmodelsaresubjecttochangewithoutnotice.