CONTENTS

2.5 Precautions for Work ............................................................................... 51

2 5.1 Compaction operation.......................................................................51

2.5.2 When going downhill.........................................................................51

2.5.3 On a slope.........................................................................................51

2.6 Applicable Jobs........................................................................................ 52

2.7 After Operation ........................................................................................ 53

2.8 Loading and Unloading............................................................................ 53

2.8.1 Use of a trailer equipped with a winch .............................................. 54

2.8.2 Self-propelling ................................................................................... 54

2.9 After Loading the Machine....................................................................... 55

2.10 Transportation.......................................................................................... 55

2.11 Operation in Cold Weather ...................................................................... 55

2.11.1 Fuel oil and grease............................................................................ 55

2.11.2 Coolant.............................................................................................. 56

2.11.3 Battery............................................................................................... 57

2.12 When the Cold Season is Over ............................................................... 58

2.13 For a Long Storage Period ...................................................................... 58

2.14 During the Storage Period ....................................................................... 59

2.15 When the Battery has Discharged ...........................................................59

2.15.1 Connection and disconnection of booster cables.............................. 60

3 PERIODIC MAINTENANCE.............................................................................. 62

3.1 Precautions.............................................................................................. 62

3.1.1 Lifting the machine by hoist............................................................... 65

3.2 Walk-around Checking ............................................................................ 66

3.2.1 Tire inflation pressure check ............................................................. 67

3.2.2 Checking for external injury to a tire.................................................. 67

3.3 Periodic Maintenance Points ................................................................... 68

3.4 Maintenance Procedure........................................................................... 70

(1) Every 10 service hours or daily......................................................... 70

(2) Every 50 service hours......................................................................73

(3) Every 250 service hours....................................................................75

(4) Every 500 service hours....................................................................78

(5) Every 1000 service hours..................................................................81

(6) As required........................................................................................ 83

3.5 Consumable Parts ................................................................................... 88

3.6 Fluid and Lubricant Capacities ................................................................ 90

3.7 Electric Wiring Diagram ........................................................................... 92

4 SPECIFICATIONS ............................................................................................ 95

CONTENTS

CONTENTS

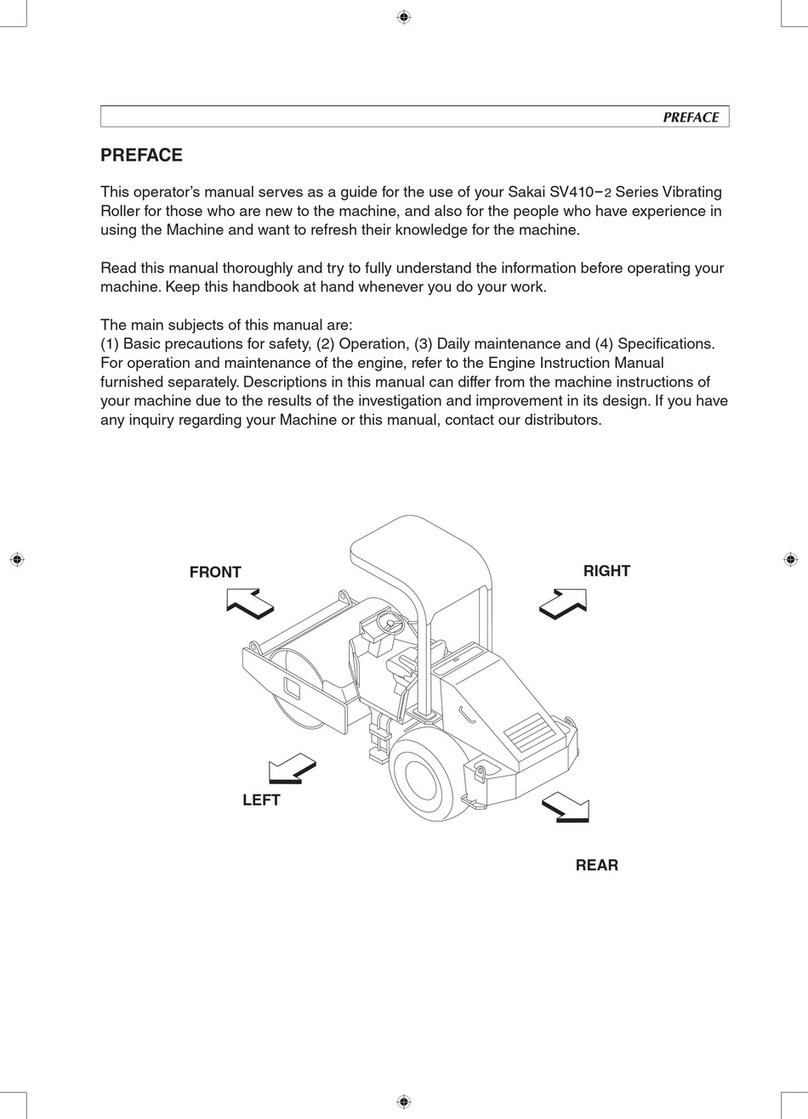

PREFACE

MACHINE AND ENGINE IDENTIFICATION NUMBERS ...................................... 1

SAFETY NOTICES................................................................................................ 2

1 BASIC SAFETY PRECAUTIONS...................................................................... 4

1.1 General Precautions................................................................................ 4

1.2 Preparation for Safe Operation................................................................ 8

1.3 Before Starting the Engine....................................................................... 9

1.4 After Starting the Engine.......................................................................... 11

1.5 During Operation ..................................................................................... 12

1.6 Loading and Unloading............................................................................ 16

1.7 Transportation.......................................................................................... 16

1.8 Handling the Battery ................................................................................ 17

1.9 Towing ..................................................................................................... 18

1.10 Before Servicing ...................................................................................... 19

1.11 During Servicing ...................................................................................... 21

1.12 Safety Decals........................................................................................... 24

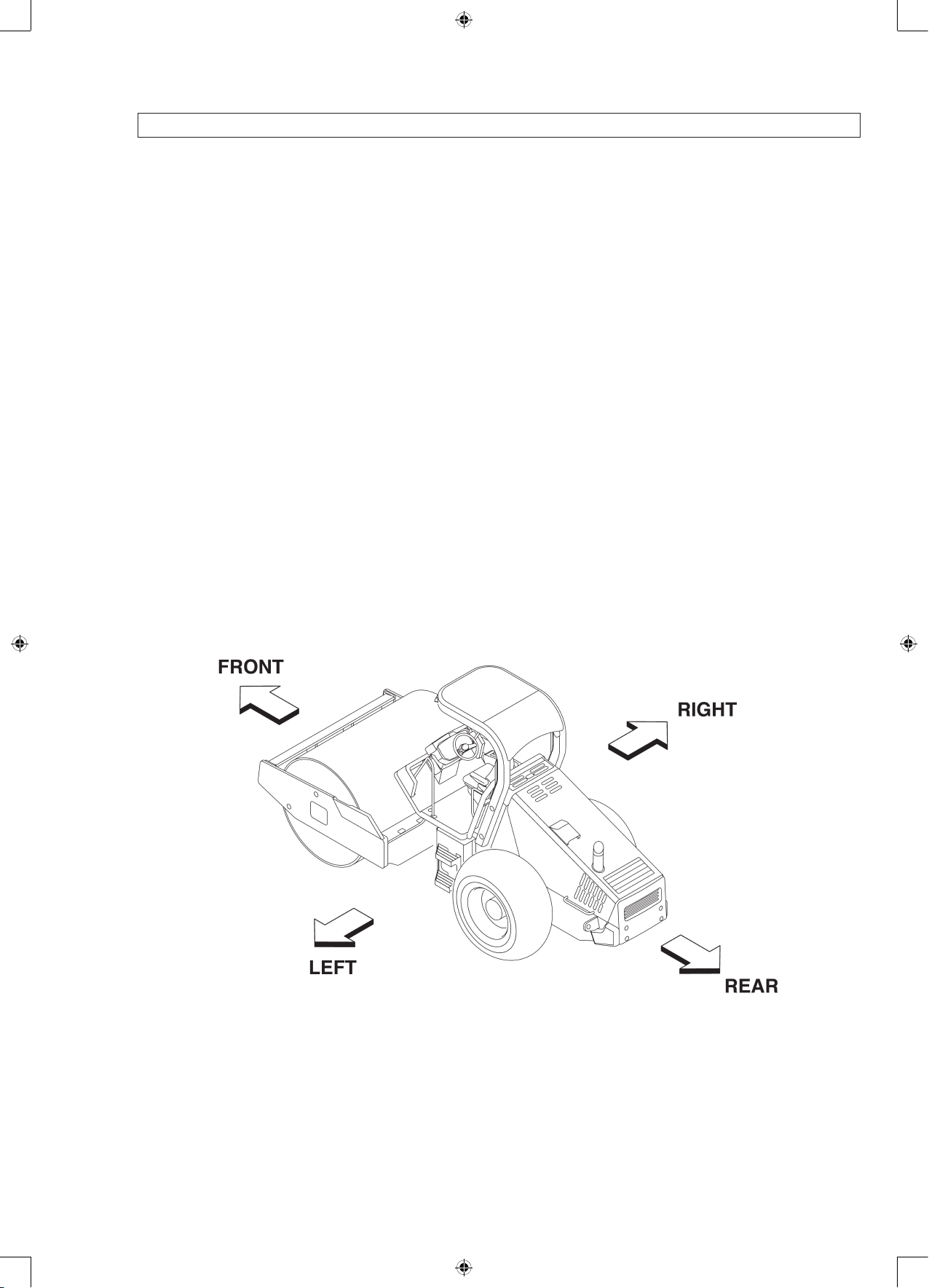

2 OPERATION ..................................................................................................... 26

2.1 Instruments and Controls......................................................................... 26

2.1.1 Operator’s station.............................................................................. 26

2.1.2 Gauges, indicator lamps and warning lamps .................................... 27

2.1.3 Switches............................................................................................ 31

2.1.4 Operating levers / pedals .................................................................. 35

2.1.5 Unloader valve .................................................................................. 36

2.1.6 Fuse box ........................................................................................... 37

2.2 Handling and Adjustments....................................................................... 38

2.2.1 Seat adjustment ................................................................................ 38

2.2.2 Scraper adjustment and replacement ............................................... 39

2.2.3 Disengaging the brake when towing ................................................. 40

2.2.4 Engine troubleshooting ..................................................................... 41

2.3 Operation ................................................................................................. 42

2.3.1 Before-starting inspection ................................................................. 42

2.3.2 Starting the engine............................................................................ 43

2.3.3 After starting the engine.................................................................... 44

2.3.4 Traveling ........................................................................................... 45

2.3.5 Stopping / Parking............................................................................. 47

2.3.6 Stopping the engine .......................................................................... 48

2.3.7 Check after stopping the engine .......................................................48

2.4 Vibratory Operation.................................................................................. 49