Safety Precautions

Please read the following safety precautions carefully. Failure to follow safety precautions could result in death

or serious injury.

Important:

• Installation of equipment in corrosive, combustible or explosive environment is strictly prohibited.

• Do not use oxygen, acetylene, poisonous gas or any other gas that will cause an explosion during equipment

leak test.

Warning:

• Installation and maintenance should be performed by qualied personnel who are familiar with the product,

local codes and regulations.

• The equipment must be installed according to local rules and regulations.

• Field-installed wiring must comply with local codes and regulations, and must be carried out by qualied

personnel.

• Power supply must comply with unit’s name plate specications.

• The unit must be GROUNDED to prevent possible hazard due to insulation failure.

• Disconnect all electrical power before servicing in order to prevent electrical shock or injury caused

by direct contact with moving parts.

• When working with live electrical components, have a qualied electrician or other individual who has been

properly trained in handling live electrical components to perform these tasks.

• Electrical wiring must not be in contact with refrigerant piping, compressor or any moving parts of

the fan motors.

Caution:

• Avoid direct contact with sharp edges and coil surfaces, which are potential hazards for injuries.

• Ensure that the drainage piping is connected properly to prevent leakage of condensate water.

• Do not overcharge the equipment. Overcharging will cause over-current and damage the compressor.

Notice:

• This manual should be returned to unit’s designated place when installation is complete.

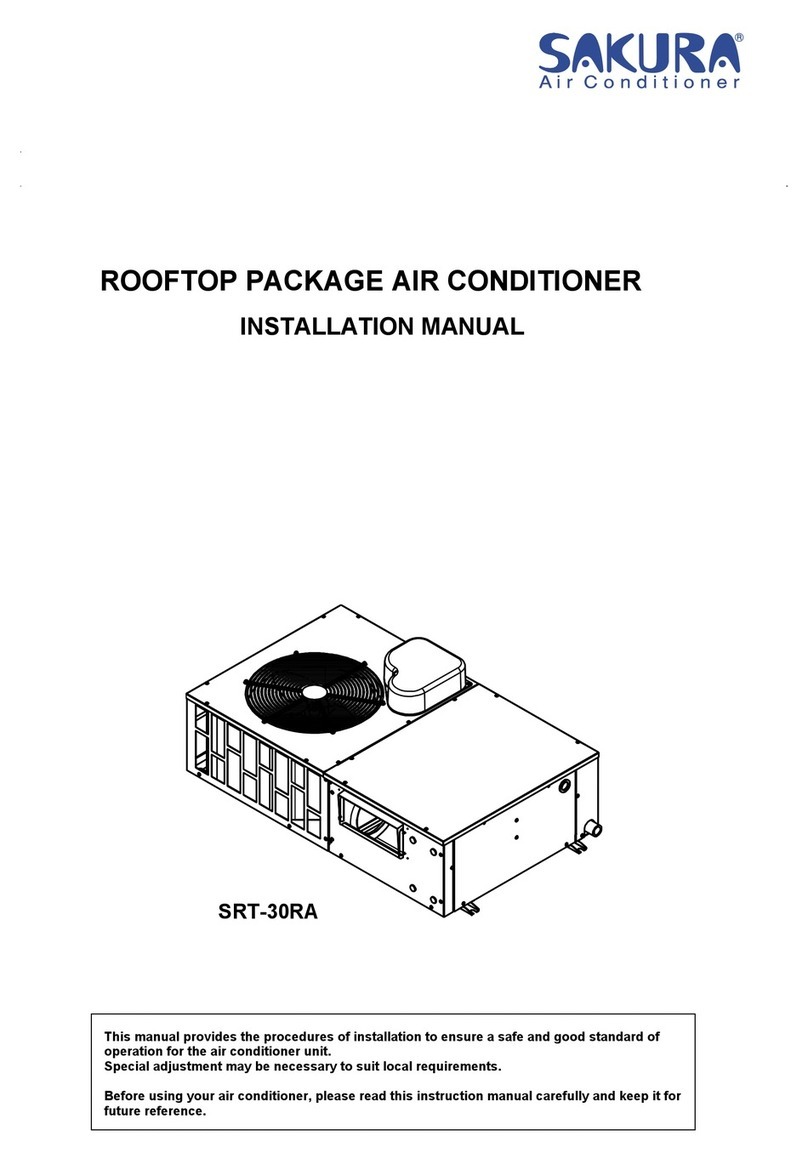

• This manual should be read carefully before installation. Unit installation and service should be performed

by experienced technicians in accordance with manual’s procedures to achieve normal and reliable unit

operation.

• This manual does not cover all unit differences and problems that may arise during installation.

Please contact our local sales ofce for further information and assistance.

• Warning and Caution will appear in appropriate sections throughout this manual, which should be rmly

followed to ensure safety and better operation performance. We claim no liability for unqualied

installation or service.

• The manufacturer reserves the right to revise any of the specications and designs contained herein at any

time without prior notication.

• Please refer to Technical manual for unit’s General Data and Controller Features.

Sakura Air-cooled Split Ducted Air Conditioner