User´s Manual HardyTest D700®

6.5.2 Average Times Setting...................................................................................................... 16

6.5.3 Material Setting .................................................................................................................. 16

6.5.4 Hardness Scale Setting .................................................................................................... 17

6.5.5 Tolerance Limit Setting ..................................................................................................... 17

6.5.6 Hardness/бb Setting.......................................................................................................... 17

6.6 PRINT FUNCTION ...........................................................................................................................18

6.6.1 Print Current ....................................................................................................................... 18

6.6.2 Print Memory ...................................................................................................................... 18

6.6.3 Print All Memory................................................................................................................. 18

6.6.4 Paper Feeding.................................................................................................................... 18

6.7 MEMORY MANAGER...................................................................................................................... 18

6.7.1 View from No.1 Group/View from Ending Group .......................................................... 19

6.7.2 View from Selected No. Group ........................................................................................ 19

6.7.3 Data Transfer...................................................................................................................... 19

6.7.4 Delete by Group No. ......................................................................................................... 19

6.7.5 Delete All Data ................................................................................................................... 20

6.7.6 Deletion Confirmation ....................................................................................................... 20

6.8 BROWSING MEMORY DATA GROUPS.............................................................................................. 20

6.9 SYSTEM SET ..................................................................................................................................21

6.9.1 LCD Brightness Set........................................................................................................... 22

6.9.2 Time Date Set .................................................................................................................... 22

6.10 SOFTWAR E INFORMATION............................................................................................................22

6.11 SYSTEM CALIBRATION.................................................................................................................22

6.12 EL BACKGROUND LIGHT............................................................................................................. 23

6.13 AUTO POWER OFF ....................................................................................................................... 23

6.14 PAPER LOADING ..........................................................................................................................23

6.15 BATTERY CHARGE .......................................................................................................................24

6.16 BATTERY REPLACEMENT .............................................................................................................24

6.17 CONNECTION OF DATA TRANSMISSION CABLE ............................................................................24

7 FAULT ANALYSIS & EVA C UATION ............................................................................................ 24

8 SERVICING & MAINTENANCE ................................................................................................... 25

8.1 IMPAC T DEVICE SERVICING ........................................................................................................... 25

8.2 NORMAL MAINTENANCE PROGRAM .............................................................................................. 25

9 CALIBRATION TIME ..................................................................................................................... 25

10 NOTICE OF TRANSPORT AND STORAGE CONDITIONS ................................................... 25

APPENDIX ........................................................................................................................................... 26

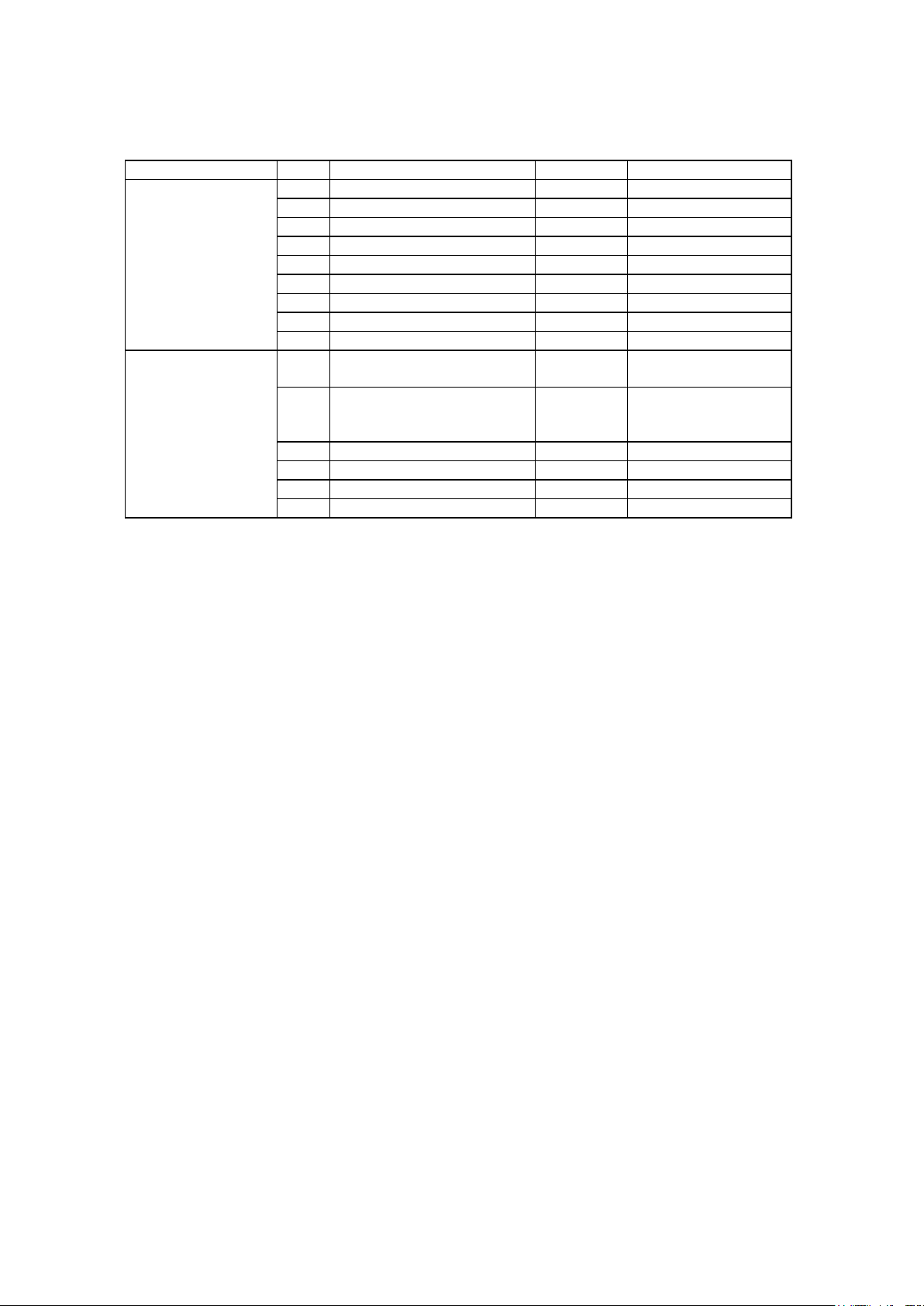

TABLE 1HARDNESS VALUES MATERIALS............................................................................................ 26

TABLE 2MAT E R I A L STRENGTH ........................................................................................................... 27

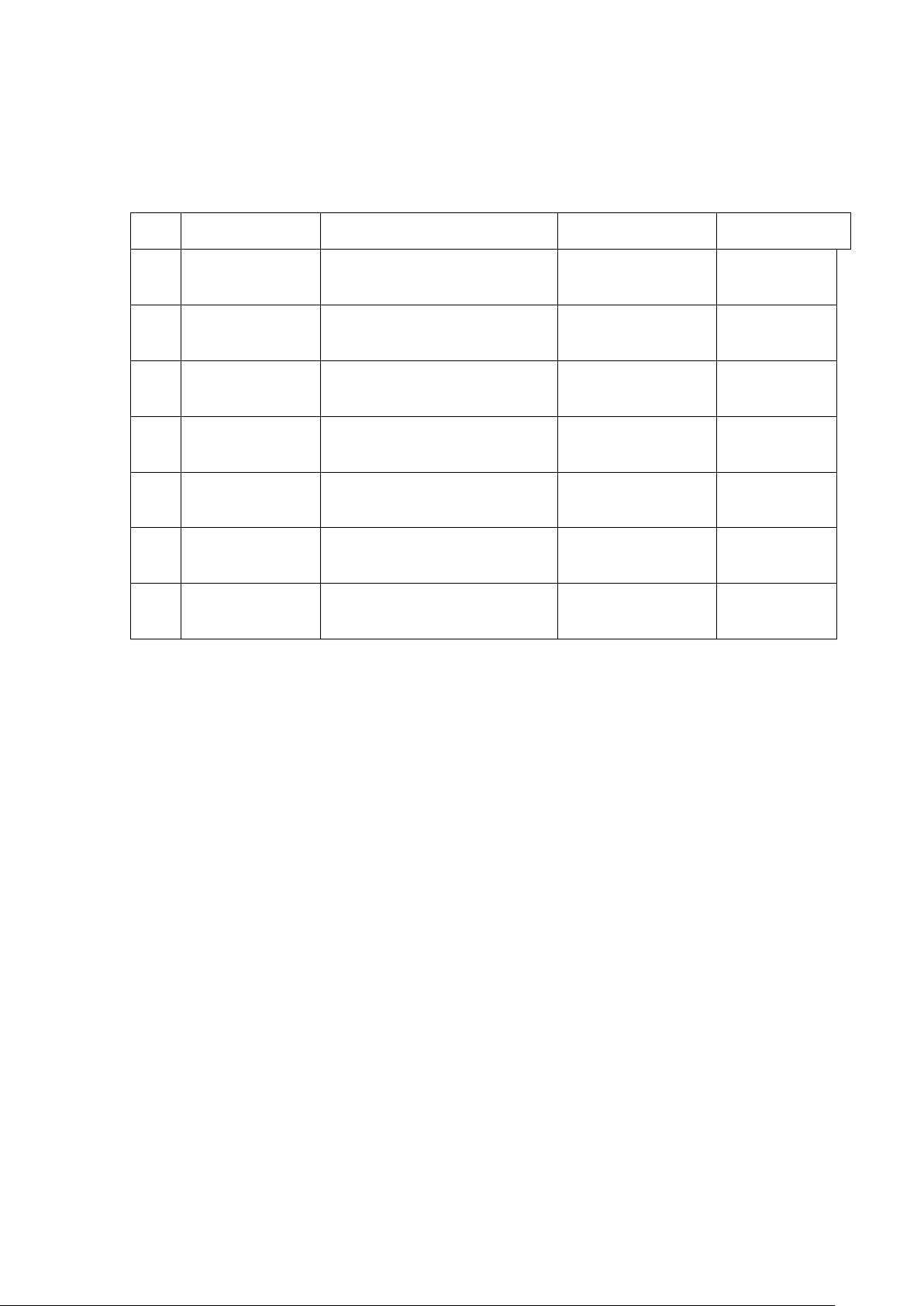

TABLE 3TECHNICAL DETAILS IMPAC T DEVICES.................................................................................. 28

TABLE 4SUPPORTING RINGS ...............................................................................................................29

TABLE 5SPECIFICATIONS ....................................................................................................................30