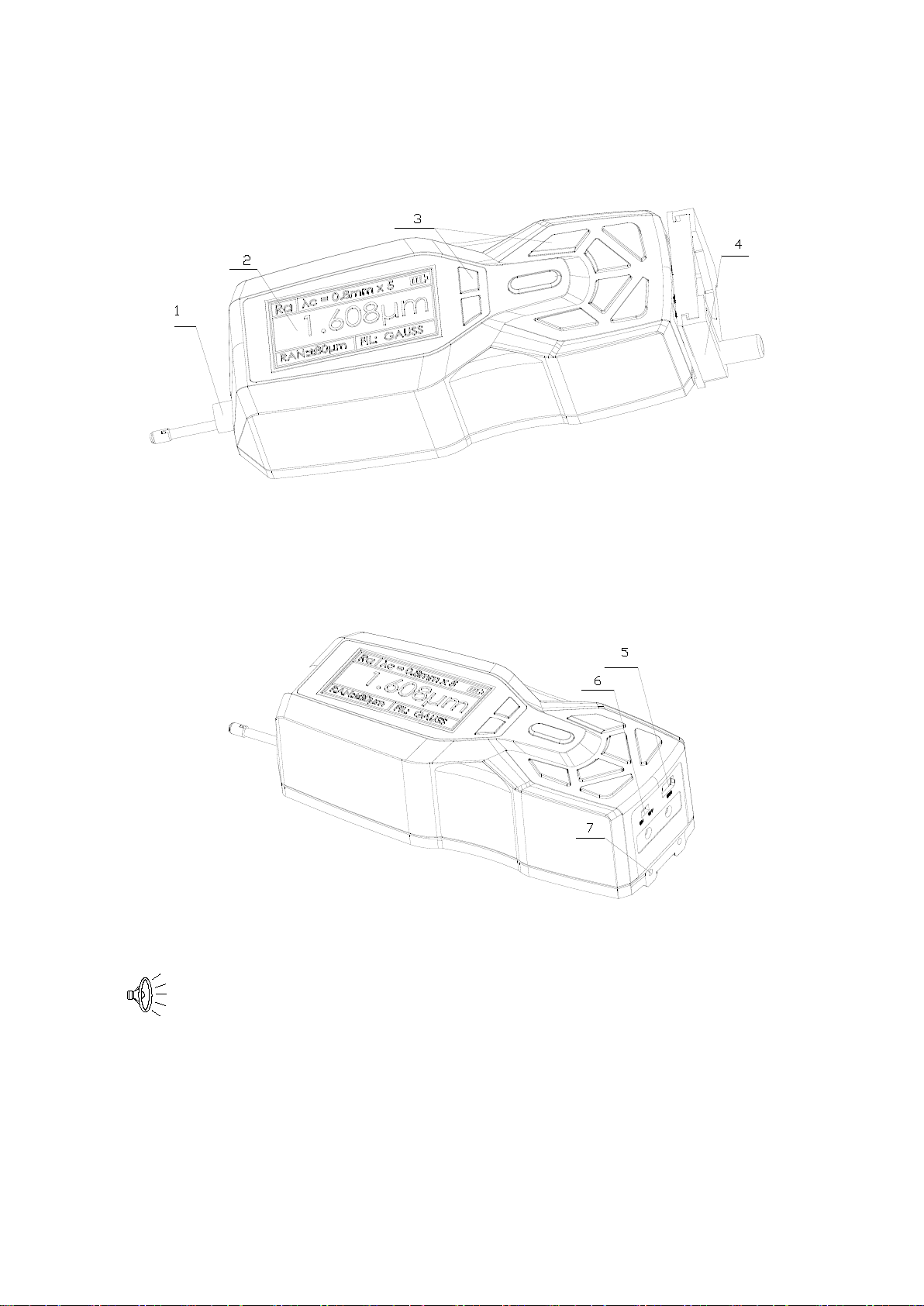

1 Roughness tester overview

The surfaces roughness tester is suitable for shop floor use and mobile measure to need of a

small handheld instrument, it operation simple, function overall, measure fast, accuracy stability,

take convenience. This tester applies to production site and can be used to measure surface

roughness of various machinery-processed parts. This tester is capable of evaluating surface

textures with a variety of parameters according to various national standards and international

standard. The measurement results are displayed digital/graphically on the OLED and can be

outputed to the printer.

1.1 Features

Electromechanical integration design, small size, light weight, easy to operation;

DSP chip control and data processing, high speed, low power consumption;

Large measurement range;

14 parameters: Ra、Rq、Rz、Rt、Rp、Rv、R3z、R3y、RzJIS、Rs、Rsk、Rku、Rsm、Rmr

128 × 64 OLED dot matrix display, digital or graphic highlight display; no viewing angle;

Display full information, intuitive and graphical displays all parameters;

Compatible with ISO, DIN, ANSI, JIS multiple national standards;

Built-in lithium-ion rechargeable battery and control circuit, high capacity, no memory effect;

There are remaining charge indicator, charging hint;

Tester has charging instructions, the operator can readily understand the level of charge

Can work more than 20 hours while the power is enough;

Large capacity data storage, can store 100 item of raw data and waveforms;

Real-time clock setting and display for easy data recording and storage;

With automatic sleep, automatic shutdown power-saving features;

Reliable circuit and software design of prevent the motor stuck;

Instrument can display a variety of information tips and instructions. For example Measurement

result display, the menu prompts and error messages;

Metal case design, rugged, compact, portable, high reliability;

Can connected to the computer and printer;

All parameters can be printed or print any of the parameters which set by the user;

Optional curved surface pickup sensor, holes sensors, measurement stand, Sheath of sensor,

extension rod, printer and analysis software;

1.2 Measurement principle

When measuring roughness of part surface, the pickup is placed on the surface of the part and

then tracing the surface at constant rate. The pickup acquires the surface roughness by the sharp

stylus in pickup. The roughness causes displacement of pickup which results in change of inductive

value of induction coils thus generate analogue signal which is in proportion to surface roughness at

output end of phase-sensitive rectifier. This signal enters data collection system after amplification

and level conversion. After that, those collected data are processed with digital filtering and

parameter calculation by DSP chip and the measuring result can be read on OLED, printed through

printer and communicated with PC.