Table of Content

1General introduction.............................................................................................3

2 Working principles................................................................................................5

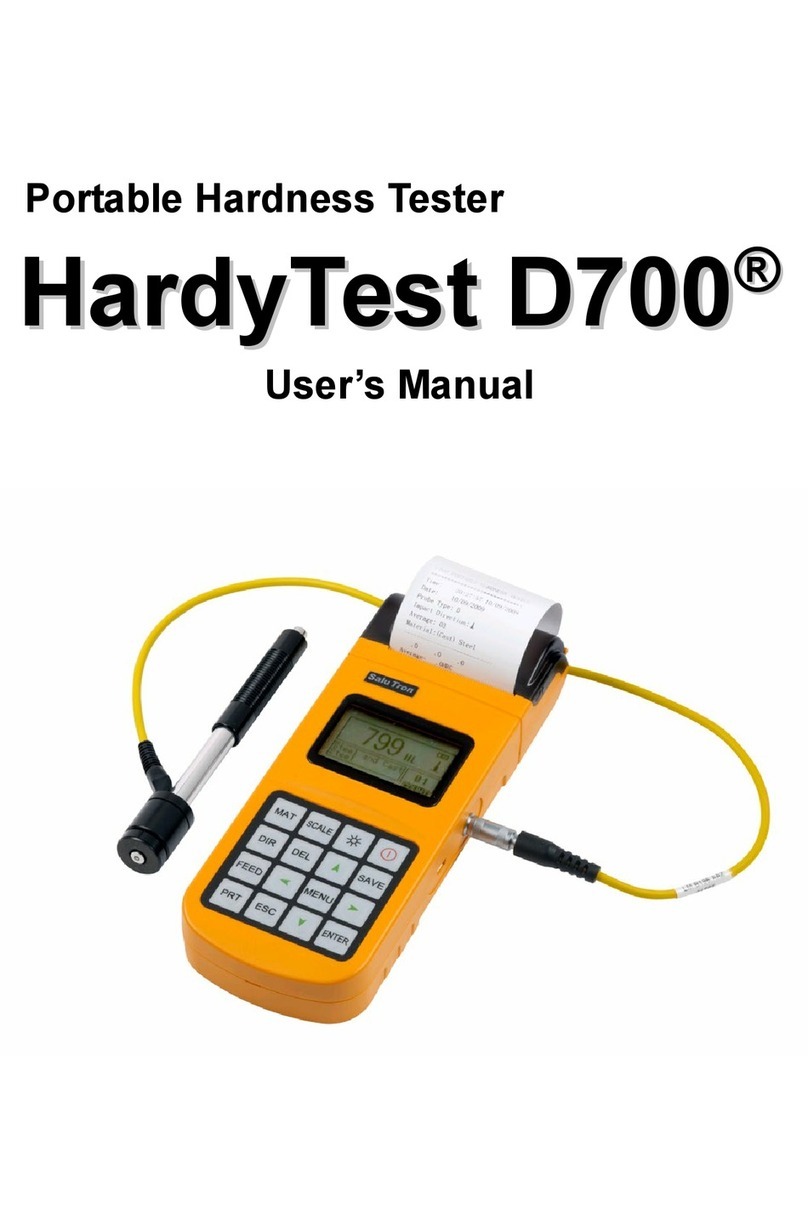

3 Description of the gauge.....................................................................................6

5 Entry into service ..................................................................................................8

5.1 Measurement preparation.........................................................................................................8

5.2 Turn on/off.................................................................................................................................9

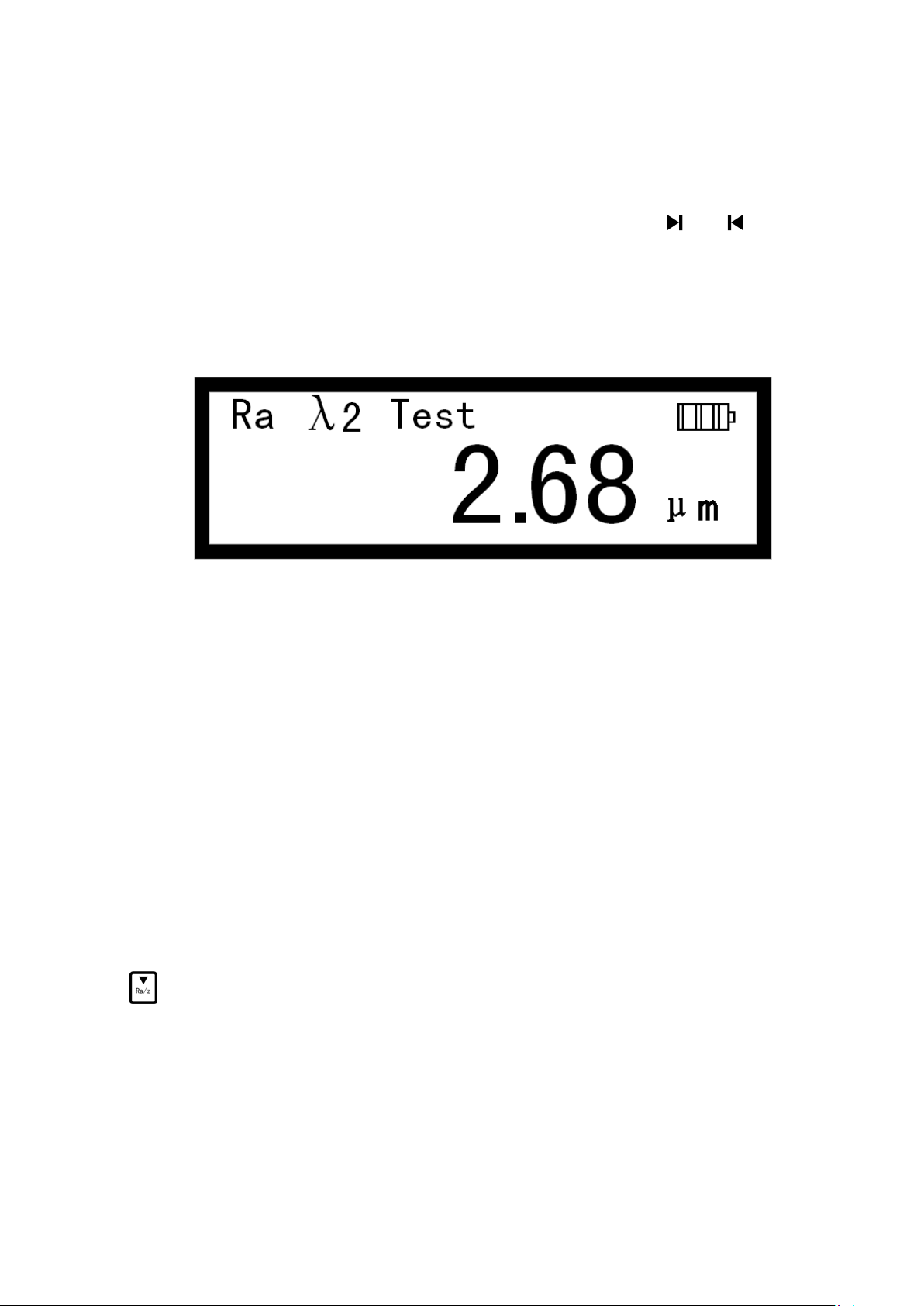

5.3 Selecting parameters.................................................................................................................9

5.4 Measuring................................................................................................................................10

5.5 Calibration ..............................................................................................................................11

5.6 Battery recharge......................................................................................................................12

6. Daily maintenance..............................................................................................12

6.1 Maintenance............................................................................................................................12

6.2 Reparation...............................................................................................................................13

7. Terminology.........................................................................................................13