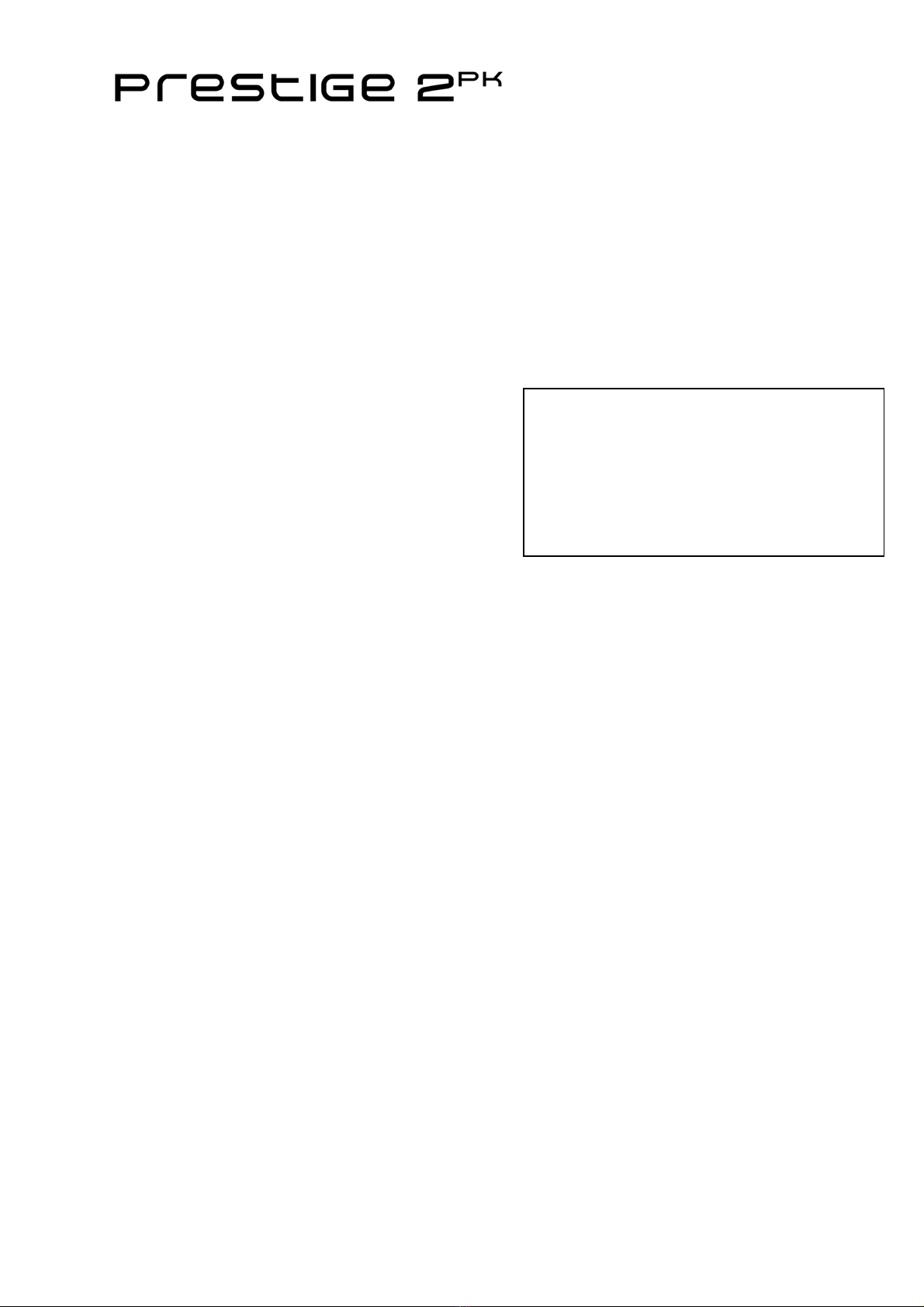

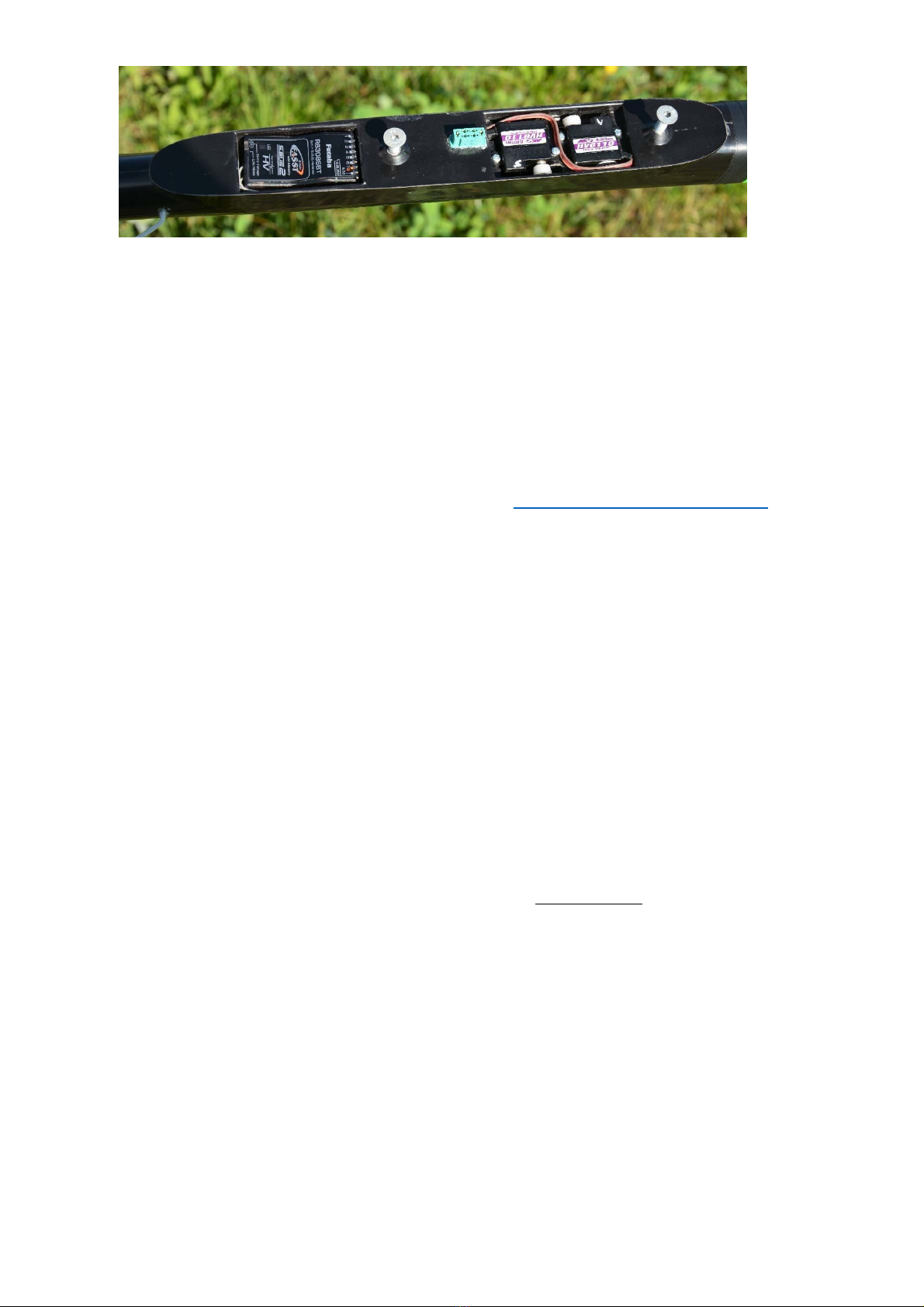

Servos and receiver installed in fuse

Mount elevator and rudder and secure in neutral with some tape. Shorten the rod

for correct length by marking the total length to servo horn with a pen and then

pull forward thru opening for cutting. The coupler can be glued to the carbon rod

with Cyano and for safety pinch the coupler with a plier to ensure tight fit. Check

the connection thoroughly

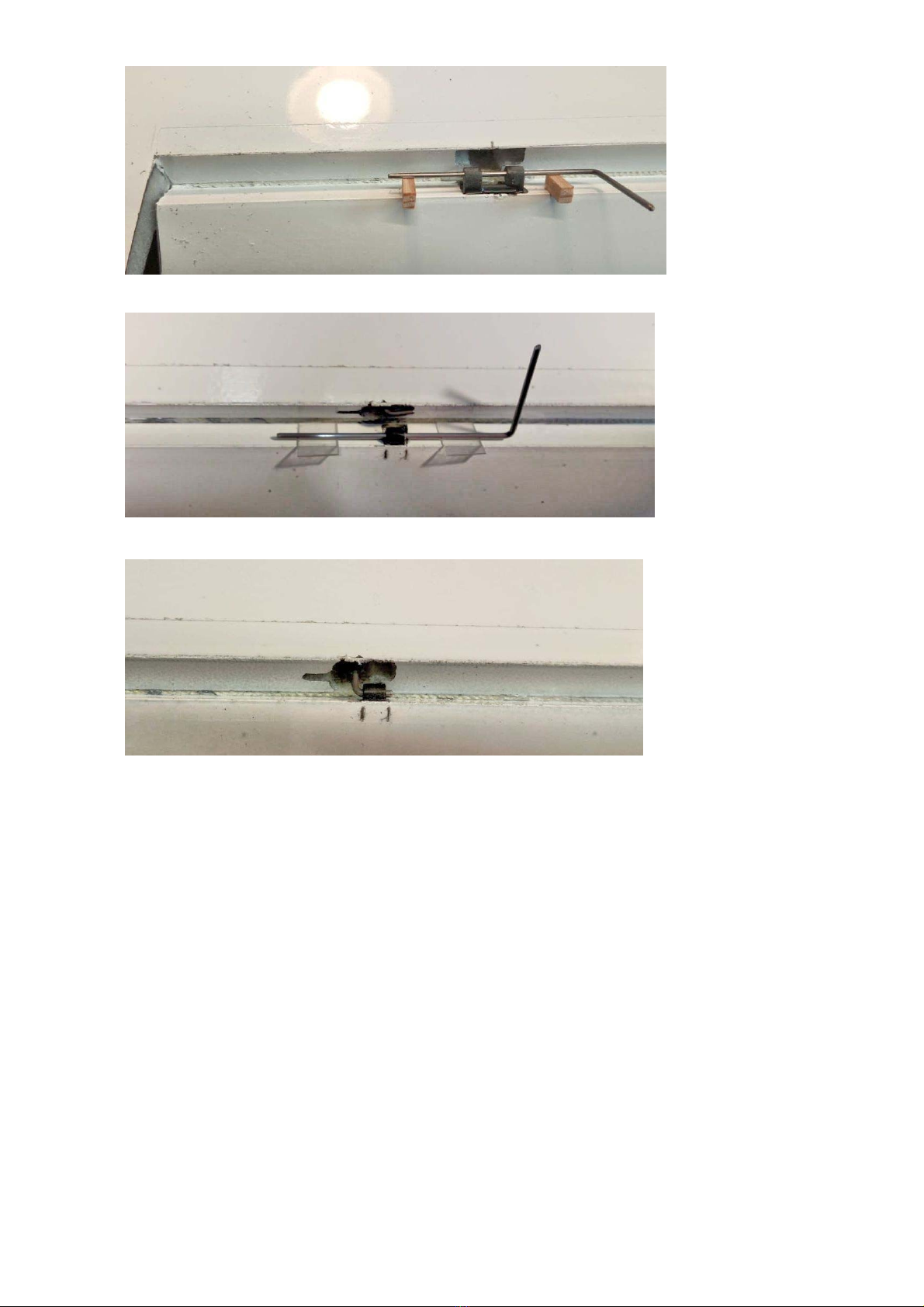

Adjust the elevator so that it is in neutral checking top and bottom airfoil (trailing

edge 24mm from fuse). Full throw is 15mm up and 17mm down. At full crow the

elevator goes down to approximately 11mm depending on crow settings for wing.

It is good to ensure more down throw (+6mm) possible after crow brake is set

Adjust rudder throw to 30mm +/-

Using excess of of 40mm might slow down the model instead of yaw motion

Fuse installation on youtube by Flightcomp: https://youtu.be/xG_r3nwUsmw

Assembling the model:

Attach the rudder to the fuse and insert the screw provided to secure the rudder.

Secure with a tiny piece of tape round the front part. Carefully push the ball link

in place and check that they move freely. Pinch the plastic with a plier to free

them up if they are tight. The ball link can be removed by using a flat screwdriver

clicking it off again.

Screw on the elevator and be sure the pushrod pin is inserted before.

Screw on midsection wing and plug in the tips with the included joiners inserted

first in the tips completely inserted.

Attach the tips with clear tape to secure at top and around leading edge.

Check and adjust the CG (center of gravity). A suitable CG to start off is 110mm

for all conditions and 112mm from leading edge in calm conditions

Check range according to transmitter specifications.

If you can not get the necessary range you need to:

1) Check antenna locations

2) Try another transmitter

3) Try another receiver

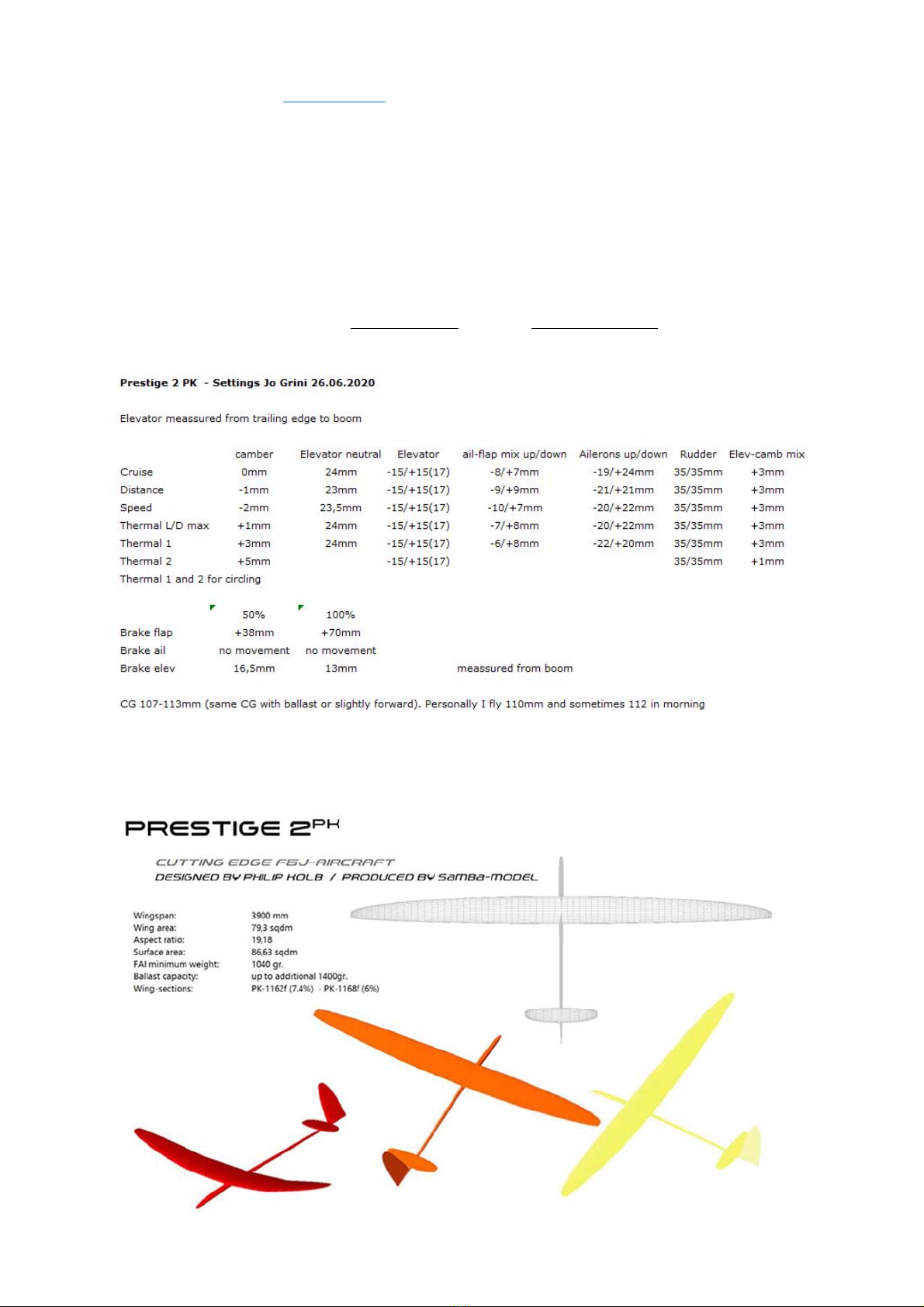

Settings:

All the latest detailed settings can be found on www.F3J.com.

These are settings from some of the world’s best pilots.

You will find these setting a very good starting point.

Wings cannot stay in the sun without wing covers. Covers prevent excessive heating of

the model as there could appear some deformations of model parts when model is

overheated, or the surface could get distortions. If the reflex painted parts are not

protected against the sun, the reflex effect will fade much earlier even if there is used

layer of paint with UV filter.

Prestige 2PK specifications are without any guarantee for structural stiffness. Sudden

changes in the deflection of the controls at high speeds are also prohibited.

The model is intended for F5J competition flying and not for aerobatics.

After harder landings it is necessary to check the joiner and look for cracks as it could

cause failure of complete model in the next flights.