Page 6

the suction line. The high pressure port is open and

liquid line pressure is applied to the underside of the

thermostatic expansion valve diaphragm. This high-

side pressure instantly overcomes the bulb pressure

and supplements of the valve spring, immediately

closing the port of the expansion valve.

Upon re-energizing the solenoid coil, the low pres-

sure port of the 180 opens and allows instantaneous

relief of pressure under the thermostatic expansion

valve diaphragm and normal operation of the ther-

mostatic expansion valve.

RECOMMENDATIONS

All refrigeration and air conditioning systems

should be protected from moisture and other sys-

tem contaminants by the Sporlan Catch-All®Filter-

Drier. When using the Type 180 Solenoid Pilot

Control, the expansion valve is used to shut off the

liquid line in place of a standard liquid line solenoid

valve. Therefore, it is essential that the system be

free of these contaminants which might prevent the

thermostatic expansion valve from seating tight.

The Type 180 may be installed either upright or on

its side. However, it should not be mounted with

the coil housing below the valve body.

INSTALLATION

In addition to first cost, flexibility of the Type

180 offers an installation savings. Standard 1/4”

soft copper tubing is the only tubing required for

the three valve connections. A C-032-F Catch-All

Filter-Drier is furnished with each Type 180, since

protection of the valve ports from system contami-

nants is important for proper operation.

ELECTRICAL

For normal summer operation of air conditioning

systems, the Type 180 Solenoid Pilot Control may

be energized through any actuating device such as

a thermostat, a micro-switch, or a manual switch.

The compressor can be operated separately through

the magnetic starter, wired with a low pressure cut-

out switch for pump down control.

If it is necessary to shut down a system for a long

period, the main liquid line or receiver valve should

be closed before de-energizing the entire system at

the main electrical service switch. This will protect

against compressor floodback if any unusual pres-

sure conditions occur during shutdown.

SERVICING SUGGESTIONS

The Type 180 Solenoid Pilot Control cannot be

taken apart in the field. To properly analyze sus-

pected trouble on an installation, it is advisable to

install a pressure gauge by means of a “T” fitting

in the external equalizer connection to the thermo-

static expansion valve.

By successively opening and closing the circuit to

the Pilot Control only, with the refrigeration sys-

tem and circulating fans or pumps in operation,

variations approximating condensing pressure and

suction pressure should be observed on this gauge.

A. If pressure does not build up rapidly to condens-

ing pressure when the Pilot Control is de-ener-

gized, proceed as follows:

1. Make certain that the electrical circuit has been

broken to the Pilot Control. Since the actuat-

ing device is generally at a remote point, we

suggest that a means for temporarily interrupt-

ing the current be made near the valve installa-

tion to facilitate servicing the equipment.

2. Check to see that no restriction exists and pres-

sure is ahead of both the Solenoid Pilot Control

and the C-032-F Catch-All Filter-Drier.

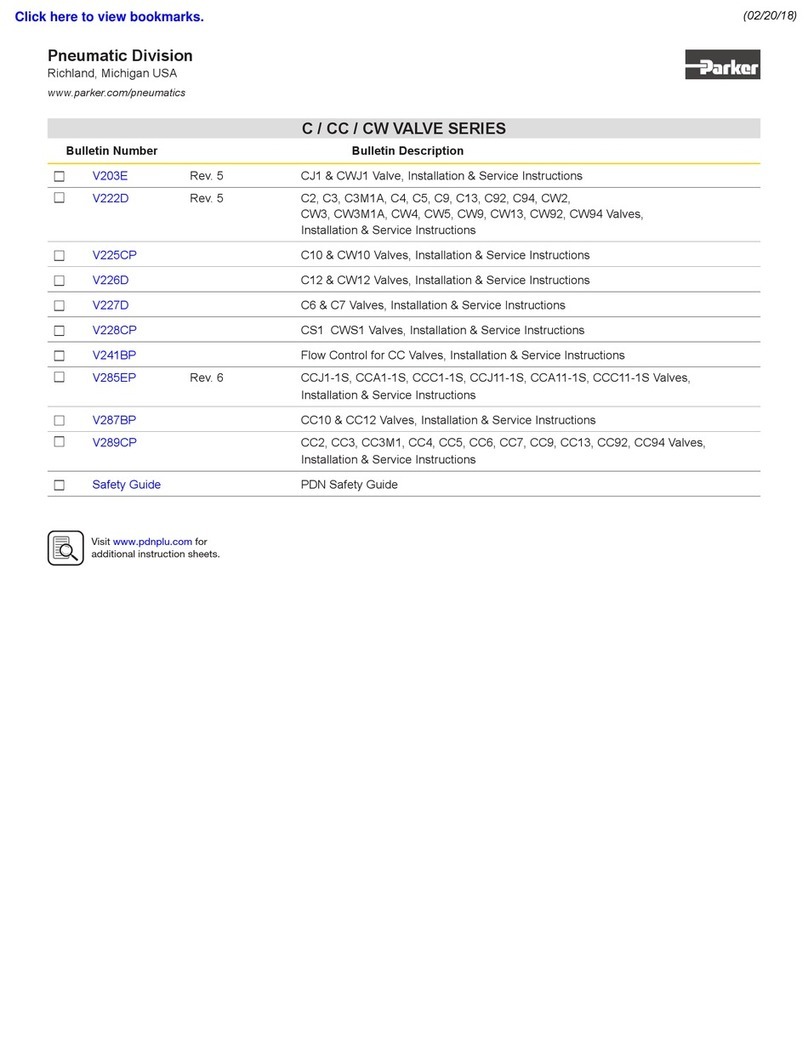

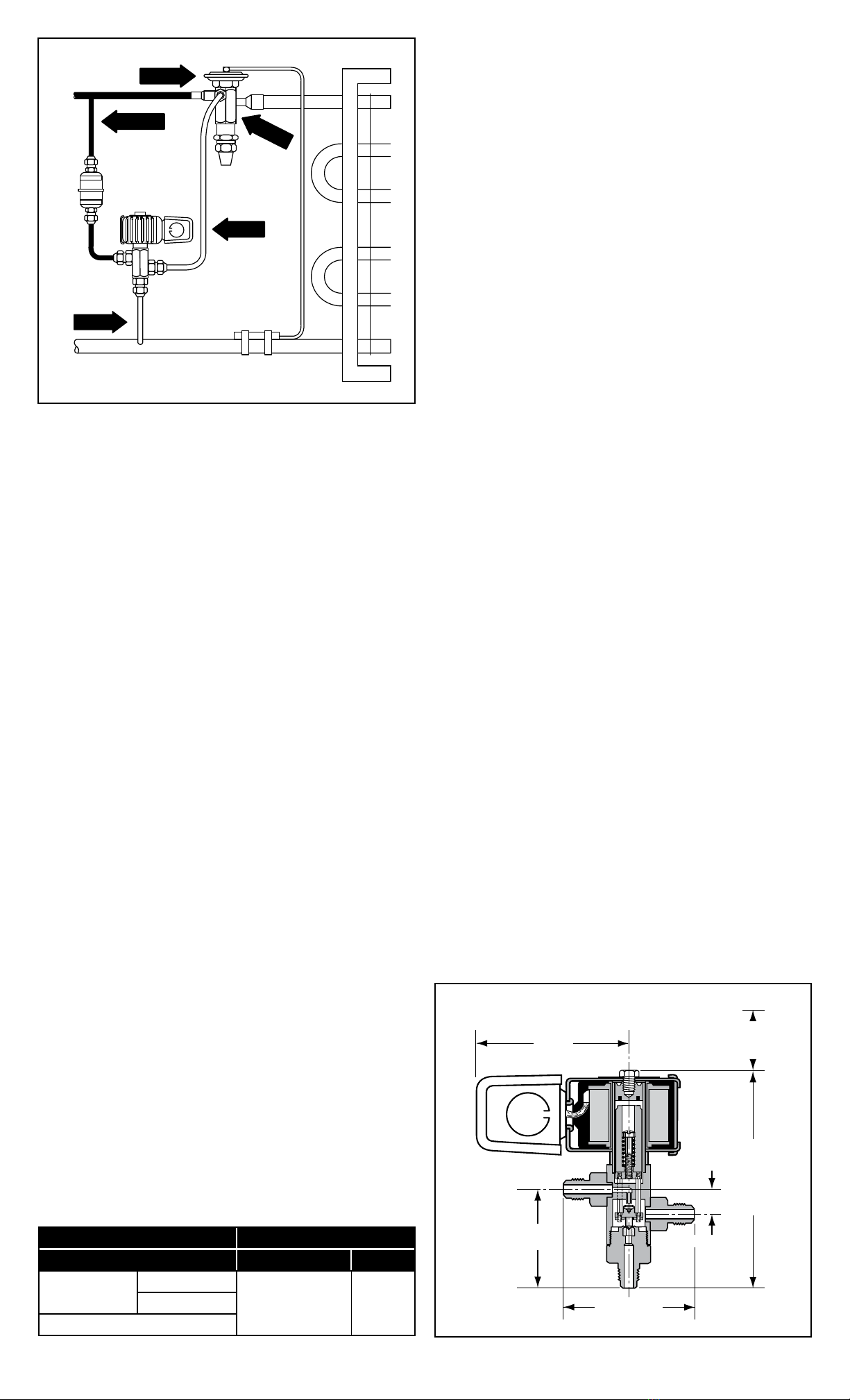

Type 180 Standard Coil Ratings

Connections - 1/4 SAE Flare Volts/Cycles Watts

MOPD

psi

300 AC 24/50-60

120/50-60

208-240/50-60

120-208-240/50-60

15225 DC

Maximum Rated Pressure - psi 500

Specifications - MKC-2 Coil

Suction

3.17”

81 mm

High

Pressure Inlet

Common

2.00”

51 mm

2.66”/ 68 mm

0.44”

11 mm

4.50”/ 114 mm

1.75”/ 44 mm

Coil Removal

Dimensions - Inches (mm)

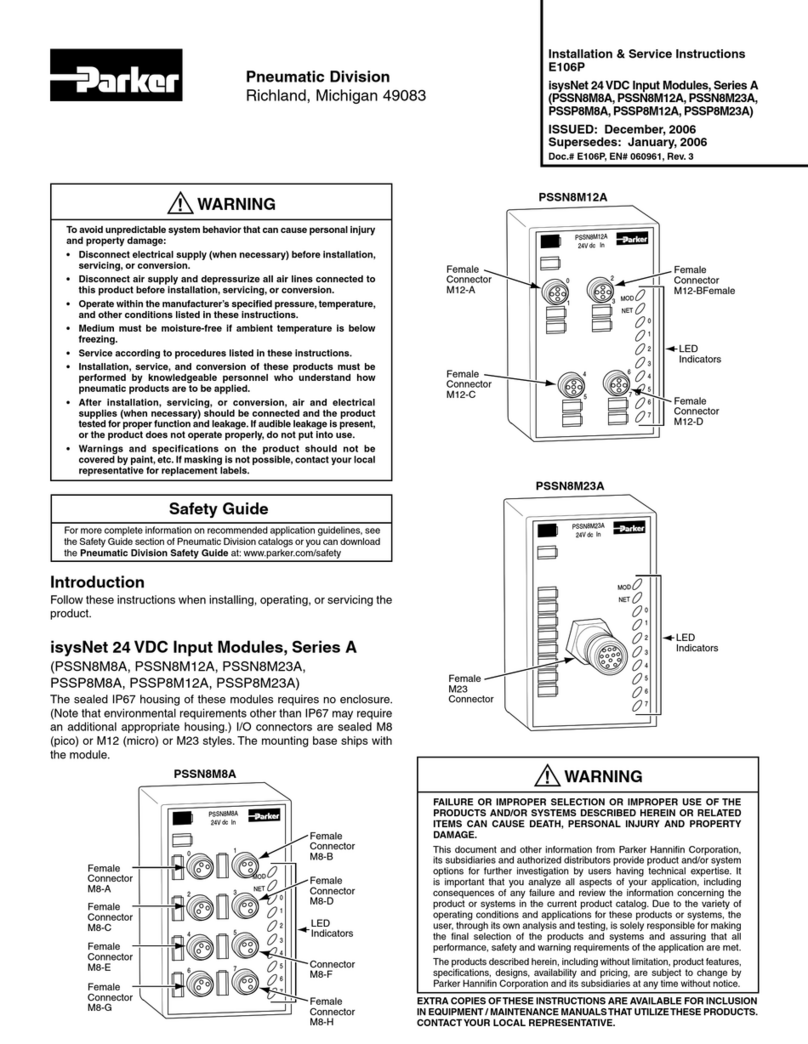

Bulb Pressure

Spring

Pressure

Evaporator

Pressure

Head

Pressure

Evaporator

Pressure

120 LBS.

49 LBS.

40 LBS.

40 LBS.

9 LBS.

Figure 4