www.larius.com

4

SIRIO PLUNGER PISTON 30:1 - 45:1

REV. 03 - 11/2020 - Cod. 150108

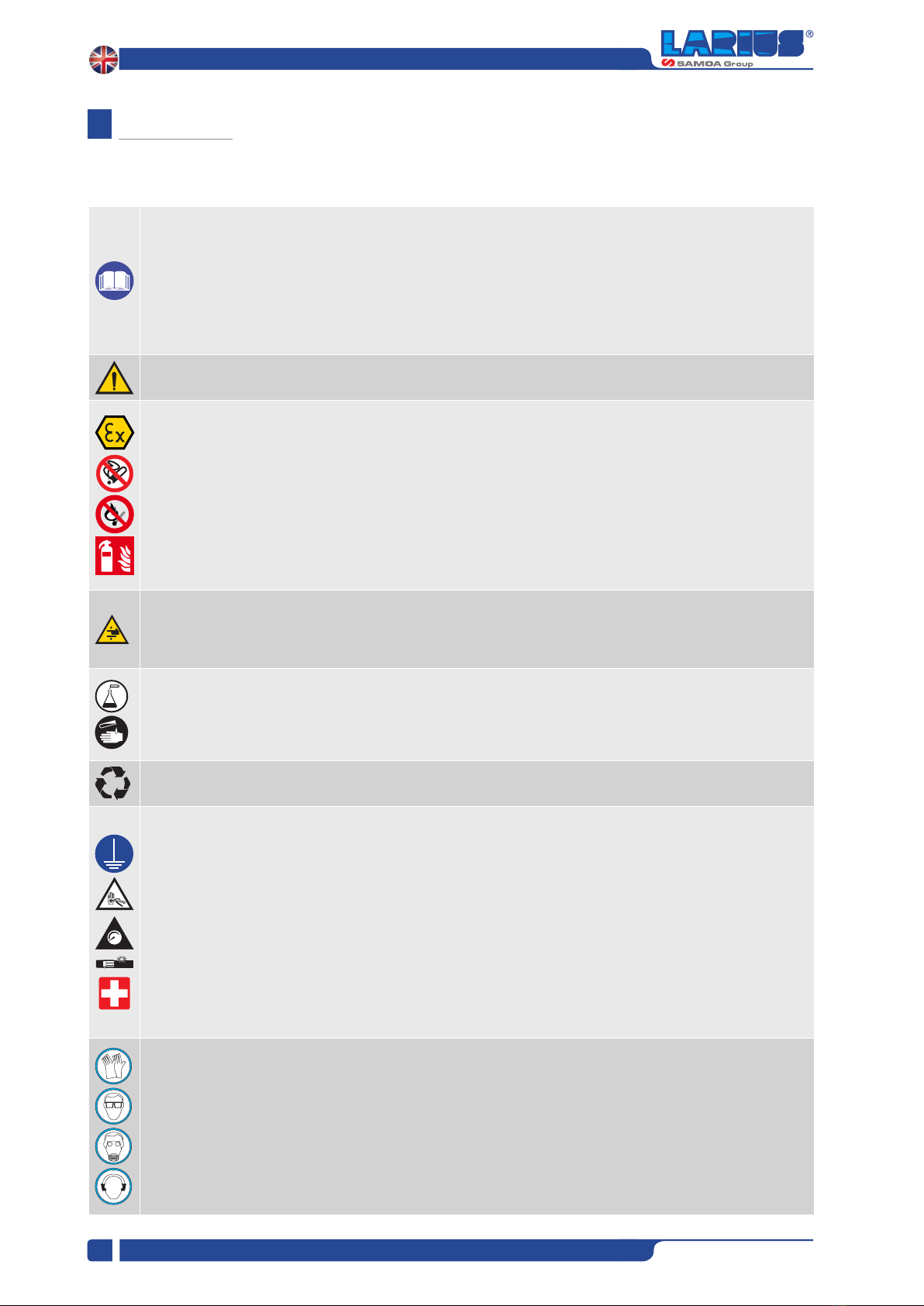

The table below provides the meaning of the symbols used in this manual in relation to using, earthing, operating, maintaining, and

repairing of this equipment.

WARNINGS

A

• Read this operator’s manual carefully before using the equipment.

• An improper use of this machine can cause injuries to people or things.

• Do not use this machine when under the inuence of drugs or alcohol.

• Do not modify the equipment under any circumstances.

• Use products and solvents that are compatible with the various parts of the equipment, and read the manufacturer’s warnings carefully.

• See the Technical Details for the equipment given in the Manual.

• Check the equipment for worn parts once a day. If any worn parts are found, replace them using ONLY original spare parts.

• Keep children and animals away from work area.

• Comply with all safety standards.

•It indicates an accident risk or serious damage to equipment if this warning is not followed.

FIRE AND EXPLOSION HAZARD

•Solvent and paint fumes in work area can ignite or explode.

•To help prevent fire and explosion:

- Use equipment ONLY in well ventilated area.

- Eliminate all ignition sources, such as pilot lights, cigarettes and plastic drop cloths (potential static arc).

- Ground equipment and conductive objects.

- Use only grounded hoses.

- Do not use trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or uids containing such solvents in

pressurized aluminium equipment. Such use can cause serious chemical reaction and equipment rupture, and result in death,

serious injury, and property damage.

- Do not form connections or switch light switches on or off if the air contains inammable fumes.

•If electrical shocks or discharges are encountered the operation being carried out using the equipment must be stopped immediately.

•Keep a re extinguisher at hand in the immediate vicinity of the work area.

• It indicates wound and nger squashing risk due to movable parts in the equipment.

• Tenersi lontano dalle parti in movimento.

• Do not use the equipment without the proper protection.

• Before any inspection or maintenance of the equipment, carry out the decompression procedure explained in this manual, and prevent

any risk of the equipment starting unexpectedly.

•Report any risk of chemical reaction or explosion if this warning has not been given.

•(IF PROVIDED) There is a risk of injury or serious lesion related to contact with the jet from the spray gun. If this should occur, IMME-

DIATELY contact a doctor, indicating the type of product injected.

•(IF PROVIDED) Do not spray before the guard has been placed over the nozzle and the trigger on the spray gun.

•(IF PROVIDED) Do not put your ngers in the spray gun nozzle.

•Once work has been completed, before carrying out any maintenance, complete the decompression procedure.

•It indicates important recommendations about disposal and recycling process of products in accordance with the environmental

regulations.

•Mark any clamps attached to earth cables.

•Use ONLY 3-wire extension cords and grounded electrical outlets.

•Before starting work make sure that the electrical system is grounded and that it complies with safety standards.

•High-pressure uid from gun, hose leaks, or ruptured components will pierce skin.

•To help prevent injection, always:

- (IF PROVIDED) Engage trigger lock when not spraying.

- (IF PROVIDED) Do not put your hand over the spray tip. Do not stop or deect leaks with your hand, body or other.

- (IF PROVIDED) Do not point gun at anyone or at any part of the body.

- (IF PROVIDED) Never spray without tip guard.

- Do pressure relief if you stop spraying or being servicing sprayer and before any maintenance operations.

- Do not use components rated less than sprayer Maximum Working Pressure.

- Never allow children to use this unit

- (IF PROVIDED) Brace yourself; gun may recoil when triggered.

If high pressure fluid pierces your skin, the injury might look like “just a cut”, but it is a serious wound!

Get immediate medical attention.

• It is obligatory to wear suitable clothing as gloves, goggles and face shield.

• Wear clothing that complies with the safety standards in force in the country in which the equipment is used.

• Do not wear bracelets, earrings, rings, chains, or anything else that may hinder the operator’s work.

• Do not wear clothing with wide sleeves, scarves, ties, or any other piece of clothing that could get tangled up in moving parts of the

equipment during the work, inspection, or maintenance cycles.