1-1

EB|14t_EN

June 2023 edition

Subject to technical changes

Safety instructions and safety measures

1 Safety instructions and safety measures

Intended use

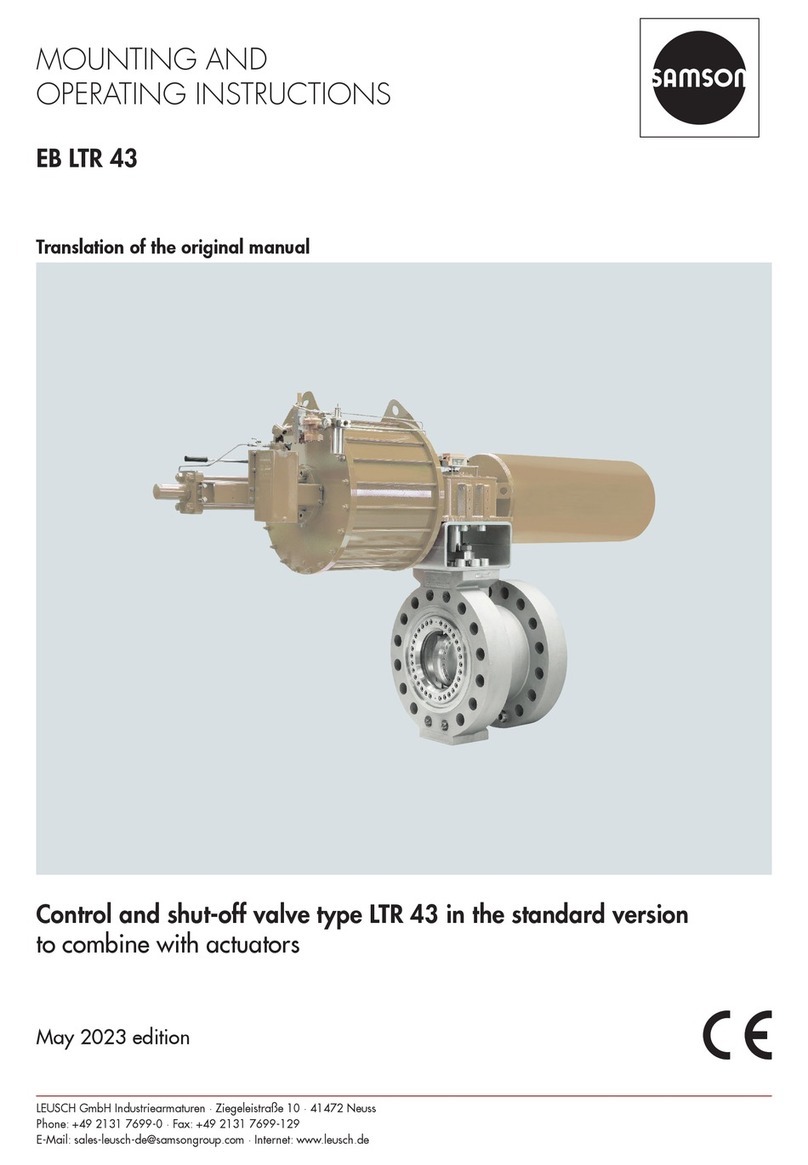

The control and shut-off butterfly valve type BR14t-LTR43 is de-

signed for use in combination with an actuator for the regulation

of the volume flow, pressure and temperature of fluid, gaseous or

vaporous media.

−The butterfly valve and its drive are designed for precisely

defined conditions (e.g. operating pressure, utilised medium,

temperature).

Therefore the operator must make sure that the butterfly valve

is only used when the conditions of use comply with the de-

sign criteria defined in the order.

If the operator would like to use the butterfly valve in other

applications or environments, they must contact PFEIFFER.

−PFEIFFER shall not be held liable for damage that result from

non-compliance with the intended use, as well as for damage

that results from external forces or external influences.

−Limits of use, areas of use and possible uses can be found in

the technical data and on the type plate.

Reasonably foreseeable misuse

The butterfly valve is not suited for the following areas of use:

−Use outside of the technical data and the limits defined by the

design.

−Use outside of the limited defined by the attachments installed

on the butterfly valve.

Furthermore, the following activities are considered unintended

use:

−Use of third-party spare parts

−Performance of maintenance and repair work that is not de-

scribed

Qualification of operating personnel

The butterfly valve may only be installed in observance of the

recognised rules of technology, commissioned, serviced and re-

paired by specialist personnel.

−Specialist personnel in terms of this installation and operating

manual are persons who, on the basis of their vocational ed-

ucation, knowledge and experience and knowledge of the

relevant standards, are capable of evaluating the assigned

tasks and identifying possible hazards.

−In the case of valves with an explosion-protection version,

personnel must have been trained or instructed or be author-

ised to work on explosion-protected devices in plants at risk

of explosion.

Personal protective equipment

PFEIFFER recommends obtaining information regarding the haz-

ards resulting from the medium in use, for example using the

GESTIS substance database.

Depending on the medium that is used and/or the respective ac-

tivity, the following protective equipment, among others, may be

necessary:

−Protective garments, protective gloves and eye protection

when using hot, cold, aggressive and/or corrosive media

−Hearing protection when working in the vicinity of the butter-

fly valve

−Industrial safety helmet

−Safety harness, if there is a danger of falling (e.g. if working

unsecured at a height)

−Safety shoes, e.g. with protection against static discharge

−Request additional protective equipment from the plant oper-

ator.

Changes and other modifications

Changes, conversions and other modifications to the valve are

not authorised by PFEIFFER. They are made at your own risk and

can lead to safety risks, for example, that cause the valve to no

longer fulfil the prerequisites required for its use.

Protective devices

If the butterfly valve switches to a defined fail-safe position when

the pneumatic energy fails, it depends on the utilised butterfly

valve, see the corresponding actuator documentation. In the case

of combinations of a butterfly valve with single-acting actuators,

the butterfly valve automatically switches to a certain fail-safe po-

sition in case of a pneumatic energy failure, see Chapter 3. The

fail-safe position corresponds to the effective direction and is in-

dicated on the type plate.

Warning of residual risks

To prevent personal injury or property damage, the operator and

operating personnel must use suitable measures to prevent the

hazards that can result from the flow medium and operating

pressure as well as the signal pressure and moving parts.

−Therefore, the operator and operating personnel must ob-

serve all the hazard information, warning information and

information in this installation and operating manual.

−Hazards that result from the specific work conditions at the

area of butterfly valve use must be determined in an individu-

al risk assessment and made avoidable by corresponding in-

structions from the operator.

Obligation of the operator to exercise diligence

The operator is responsible for proper operation as well as com-

pliance with the safety regulations.

−The operator is responsible for providing operating personnel

with this installation and operating manual as well as the ap-

plicable documents and to provide instructions on proper op-

eration.

−Furthermore, the operator must ensure that operating person-

nel and third parties are not endangered.

−The operator is responsible that the limit values for the valve

defined in the technical data are not undershot or exceeded.