1 Design and principle of

operation

The flow regulator is designed to maintain the

flow rate in the pipeline at the set point ad-

justed at the restriction.

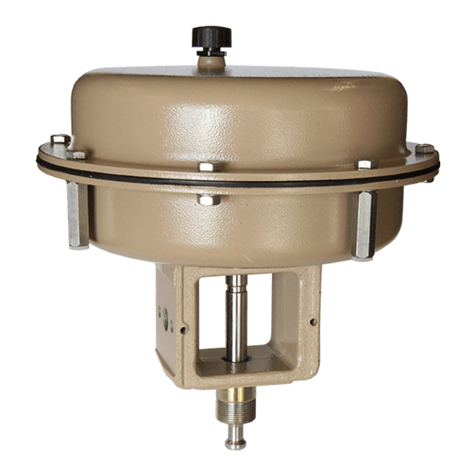

The regulator consists of a Type 2423 Valve

with a seat, plug and a restriction as well as a

Type 2426 Closing Actuator with an operat-

ing diaphragm.

The valve and actuator are delivered as sepa-

rate units and must be connected with a cou-

pling nut on site.

Type 42-36 DoT

This version allows the additional control or

limitation of the temperature by attaching a

double adapter with a thermostat.

See the Mounting and Operating Instructions:

EB 3019 EN for the double adapter and

EB 2231 EN for Type 2231, Type 2232,

Type 2233, Type 2234 and Type 2235 Control

Thermostat.

The medium flows through the valve in the di-

rection indicated by the arrow. The flow rate

is determined by the free area between the re-

striction (1.1) and the valve plug (3).

The valve plug is unaffected by pressure

changes in the medium since the upstream

and downstream pressures are balanced by

the balancing bellows (5) or the balancing di-

aphragm (5.1) (DN 125 to 250/valve bal-

anced by a diaphragm).

The principle of operation of the regulators

with valves balanced by a bellows or dia-

phragm only differ concerning the pressure

balancing. The valves balanced by a dia-

phragm have a balancing diaphragm (5.1)

instead of a bellows (5). The downstream

pressure p2acts on the inside and the up-

stream pressure p1on the outside of the dia-

phragm or bellows. As a result, the forces act-

ing on the valve plug are balanced out.

The high pressure upstream of the restriction

(1.1) is transmitted through the control line

(18) to the lower diaphragm chamber. The

low pressure downstream of the restriction

(1.1) passes through the hollow plug stem (7)

and the diaphragm stem (6) into the top dia-

phragm chamber of the actuator. The differ-

ential pressure produced at the restriction is

converted into a positioning force at the oper-

ating diaphragm (12) and is used to move the

valve plug according to the force of the differ-

ential pressure springs (14). If the flow rate in-

creases, for example, the differential pressure

at the restriction also increases. The actuator

and plug stems move in the closing direction

and the flow rate is reduced until the flow rate

set point adjusted at the restriction (1.1) is

reached. If the flow rate decreases, the re-

verse takes place.

4EB 3015 EN

Design and principle of operation