Contents

EB 2185 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible severe personal injury .........................................................8

1.2 Notes on possible personal injury ...................................................................8

1.3 Notes on possible property damage................................................................9

2 Markings on the device ...............................................................................11

2.1 Material number..........................................................................................11

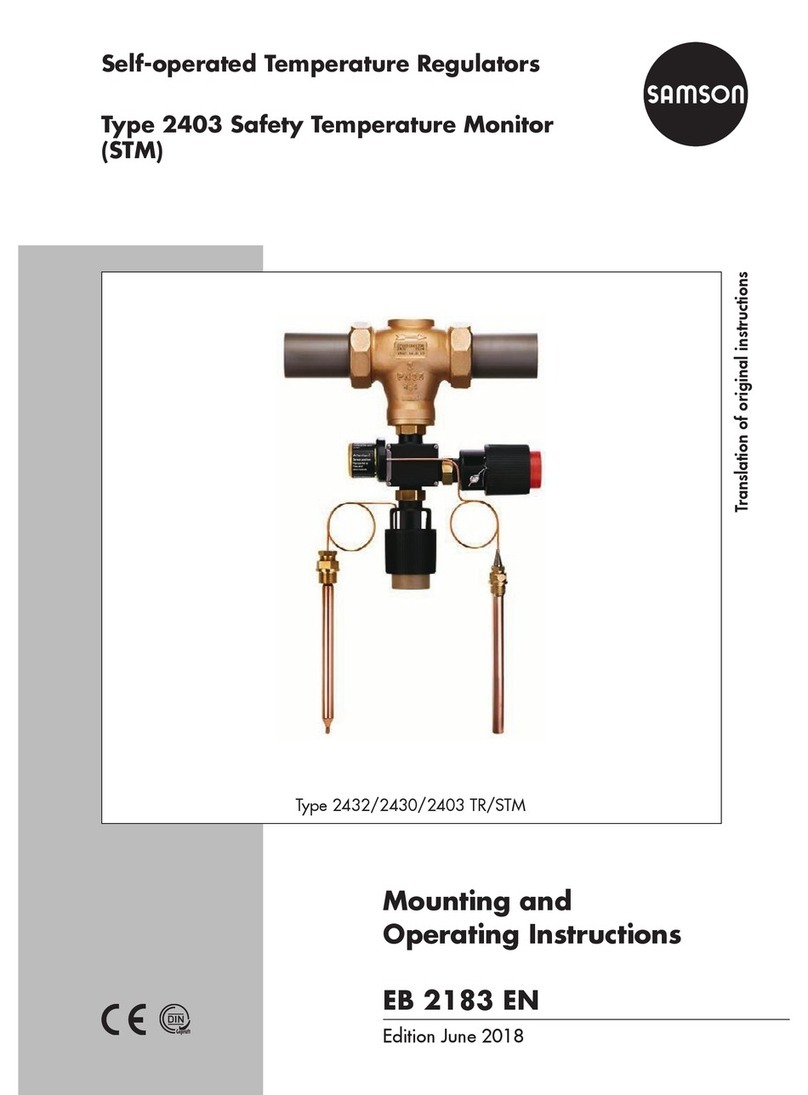

3 Design and principle of operation ................................................................12

3.1 Technical data .............................................................................................14

3.2 Process medium and scope of application......................................................14

4 Measures for preparation............................................................................22

4.1 Unpacking ..................................................................................................22

4.2 Transporting and lifting ................................................................................22

4.3 Storage.......................................................................................................22

4.4 Preparation for installation............................................................................23

5 Mounting and start-up.................................................................................23

5.1 Assembling the safety temperature limiter and valve .......................................23

5.2 Additionalttings.........................................................................................24

5.3 Temperature sensor and capillary tube...........................................................25

5.4 Electric signal transmitter ..............................................................................26

5.4.1 Retrottingasignaltransmitter......................................................................26

5.5 Start-up.......................................................................................................26

5.5.1 Gases and liquids ........................................................................................27

5.5.2 Steam .........................................................................................................27

6 Operation...................................................................................................27

6.1 Adjusting the limit temperature......................................................................27

6.1.1 Adjusting the temperature limit without using a heating bath ...........................28

6.1.2 Adjusting the temperature limit using a heating bath.......................................28

6.2 Unlocking after a fault..................................................................................30

6.3 Sensor failure ..............................................................................................30

6.4 Maintenance ...............................................................................................31

6.5 Preparation for return shipment.....................................................................32

7 Malfunctions ...............................................................................................32

8 Decommissioning and removal ....................................................................34

8.1 Decommissioning.........................................................................................34

8.2 Disposal......................................................................................................34