S&T TPMS1209T02-ER User manual

Page 1 of 28

TPMS1209T02-ER

USER MANUAL

Suzhou Sate Auto Electronic Co., Ltd

www.sate.com.cn

Page 2 of 28

Table of Contents

I. TPMS1209T02-ER, Full-time Direct TPMS

-----------------------------------3

II. Parts of TPMS1209T02-ER

--------------------------------------------------------3

III. Installation and Programming of TPMS1209T02-ER Monitor

---------4

1. Installation of Monitor

-----------------------------------------------------------4

2. Programming of Monitor

-------------------------------------------------------5

2.1Programming of Transmitter ID

-----------------------------------------7

2.2 Standard Pressure Programming

----------------------------------------7

2.3 System Time Programming

---------------------------------------------- 9

2.4 Programming of Pressure Unit

-----------------------------------------11

2.5 Deletion of Transmitter ID

-----------------------------------------------12

IV. Installation of TPMS1209T02-ER Transmitter

-------------------------------12

1. Installation of Transmitter

---------------------------------------------------------13

2. Installation of Security Lock

-----------------------------------------------------14

V. System Function of TPMS1209T02-ER

---------------------------------------17

1. Full-time Monitoring

--------------------------------------------------------------17

2. High Pressure Alarm

---------------------------------------------------------------17

3. Low pressure level 1 alarm

------------------------------------------------------18

4. Low pressure level 2 alarm

-------------------------------------------------------18

5. Low pressure level 3 alarm

-------------------------------------------------------19

6. High Temperature Alarm

----------------------------------------------------------19

7. Quick Leak Alarm

-------------------------------------------------------------------20

8. Transmitter Trouble Alarm

--------------------------------------------------------21

VI. TPMS1209T02-ER Auxiliary Functions in Normal Mode

---------------21

Alarm Record Inquiry

------------------------------------------------------------------21

VII. Specifications

-------------------------------------------------------------------------24

VIII. Frequently Asked Questions

----------------------------------------------------25

IX. Warranty Term

-------------------------------------------------------------------------27

X. Important Notes

------------------------------------------------------------------------28

Page 3 of 28

I. TPMS1209T02-ER, FULL-TIME DIRECT TPMS

TPMS1209T02-ER is direct tire pressure monitoring system for trucks

which includes 1 monitor, 1 standard booster and 2 to 38 transmitters and

it can support monitoring of up to 38 tires. The transmitter can be

screwed onto the tire instead of the valve cap and then senses the pressure

inside the tire all the time and transmits the pressure information data to

the booster by RF technology. Then the booster transmits the pressure

information data to the monitor after received and magnified it. The

monitor can receive and deal with the data, then display the pressure on

the screen. The monitor can issue different alarms if the tire pressure is at

an improper level based on the standard pressure, so as to notify the

driver to treat the problem and avoid tire busting or tire damage.

Through TPMS1209T02-ER, the driver can keep the tire running under a

proper pressure so as to avoid excess gasoline consumption and keep the

vehicle in an easily controlled state.

II. Parts of TPMS1209T02-ER

1 Monitor

6 Transmitters

6 Security Locks

1 Bracket

2 Wrenches

4 3M Dual Lock

1 User Manual

1 Standard Booster (optional)

Page 4 of 28

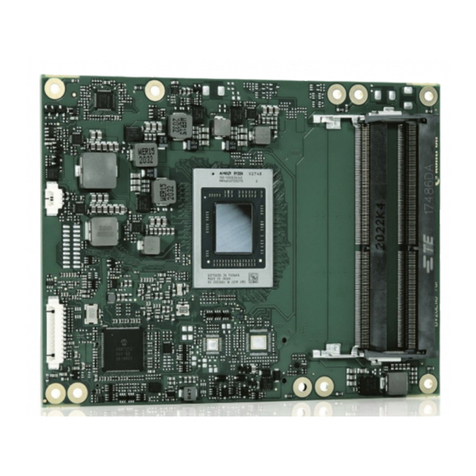

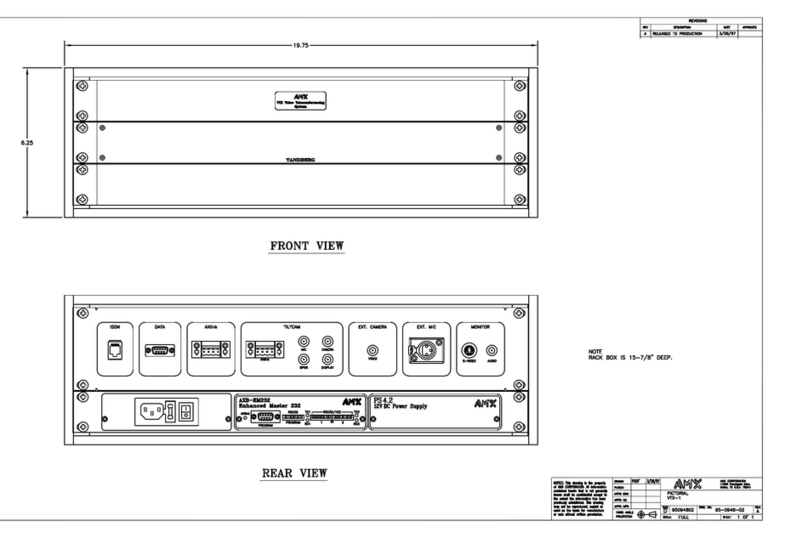

Monitor

Transmitter

III. Installation and Programming

of TPMS1209T02-ER

1. Installation of Monitor

1.1 Insert the pedestal to the back of the monitor as shown in below

picture.

1.2 Choose a suitable location to install the Monitor onto the dashboard.

Make sure to first scrub the surface of the location with alcohol. Next,

strip off the liner of the 3M Dual Lock Fastener, put the sticky side

onto the suitable location, then fix the Monitor with another side of

the 3M Dual Lock Fastener on the platform.

Install Pedestal

LCD

Screen

Key

Alarm Lamp

Pedestal

Transmitter

Security Lock

Wrench

Page 5 of 28

1.3 The monitor power wire consists of 3 different colors of wires. The

Black wire should be connected to the ground. The Red wire should

be connected to the vehicle’s continuous power supply. The Blue wire

should be connected to ignition switch, when switched to “ON”, the

blue wire is connected with 12V power.

The monitor starts to work after it is powered. At this time the monitor

cannot receive any information as the transmitters are not installed. The

screen shows “NSP”, which means there are “No Transmitters

Programmed”.

2 Programming of Monitor

Through the monitor, the user can program up to 38 transmitters ID

number and the standard pressure for each wheel. Operation steps are as

following:

3M Dual Lock

Page 6 of 28

2.1 Programming of Transmitter ID

When the monitor is powered for the first time, the screen shows

“NSP”, which means there is no transmitter programmed into it. If the

user wants to program a new transmitter into the monitor, the operation

should be finished in programming mode. At this time, make sure the

transmitter to be programmed has not been screwed onto the valve cap

yet until the programming has been finished and the monitor returns to

normal mode.

Each transmitter has 4 groups of ID, for example when program the

transmitter with ID of 001 001 001 158 to front right tire position, the

user only needs to input the last 3 digits “158”. Monitor will record the

rest 3 groups of ID automatically.

1. After monitor is powered, the screen will display “NSP”, then press P

for 3 seconds to access the system programming mode, the first

interface is for ID programming as shown below:

2. Press any of the four arrow keys to choose the transmitter position

which needs to be programmed.

3. Then press S for 3 seconds to start programming and the digit flashes,

Page 7 of 28

then press up or down arrow key to adjust the value.

4. Once finish programming of the first digit, press →to start

programming the second digit which flashes. Press up or down arrow

key to adjust the value.

5. Press →again to program the third digit which flashes. Press up or

down arrow key to adjust the value.

6. When finish programming these 3 digits, press S for 3 seconds to save

with the screen flashes twice, beep buzzes twice. Then it will

automatically switch to next tire position.

7. Follow the above operations to program ID of other transmitters.

2.2 Standard Pressure Programming

For example, set the standard pressure of front right tire to 105 psi:

1. When finish programming ID, press P to access the standard pressure

Page 8 of 28

programming mode.

2. Then press any of the four arrow keys to choose the desired tire

position.

3. Then press S for 3 seconds to set the first digit which flashes. Press up

or down arrow key to adjust the value to 1.

4. Once finished programming the first number, press →to program

the second digit which flashes and then press up or down arrow key to

adjust the value to 0.

5. Once finished programming the second number, press

→to

program the third

digit which flashes and then press up or down arrow

key to adjust the value to 5. Then press S for 3 seconds to save with the

screen flashes twice, beep buzzes twice.

Page 9 of 28

Note: The default standard pressure is set to 100 psi in factory.

2.3 System Time Programming

Function: The system clock was preset in the factory. It is the base of

the alarm record, user can check the current date and time as

follows:

1. When finish programming the standard pressure, press P to access

interface for inquiry and programming of time/date, the first

interface displays the year, 1 07 stands for the year 2007:

2. Press ↓key to access the second interface, 211 stands for November

as shown below:

Page 10 of 28

3. Press the ↓key to access the third interface, 312 stands for 12th day

as shown below:

4. Press the ↓key to access the fourth interface, 416 stands for 16

O’clock as shown below:

5. Press the ↓key to access the fifth interface, 533 stands for 33 mins.

As shown below:

Under any interface of system time inquiry, press S for 3 seconds to

start programming. For example change the year to “09”, under the

year interface, press S for 3 seconds, the second digit flashes, press up

or down arrow key to adjust the value. Then press →key, the third

number flashes, then press the up or down arrow key to adjust the value

to“9”. At last press S for 3 seconds to save the change with screen

flashes twice and beep buzzes twice. Then it automatically switches to

Page 11 of 28

next interface for programming.

2.4 Programming of Temperature and Pressure Unit

1. After program the system time, press P to access interface for

programming temperature and pressure unit. The first interface

displays the temperature unit. As shown below:

At this time, press up or down arrow key to switch to the pressure unit

interface. As shown below:

2. Under any interface displaying temperature or pressure, press S key

for 3 seconds to start programming. Take change the temperature

unit as an example: under the temperature unit interface, press S

key for 3 seconds, the temperature unit “℃” starts flashing. Press

up or down arrow key to select the needed temperature unit.

After select the desired unit, press S key for 3 seconds to save with

the beep

buzzes twice. Temperature unit will stop flashing.

Page 12 of 28

2.5 Deletion of transmitter ID

1. When finish programming temperature and pressure unit, press P to

access the transmitter deletion interface. Only the programmed and

received transmitter will be shown and only the last 3 ID digits will

be shown:

2. Press any of the four arrow keys to locate the tire position to be

deleted.

3. Press S key for 3 seconds to delete with the screen flashes twice and

beep buzzes twice to confirm the deletion. Then it automatically

switches to next transmitter location.

Note: After programming, press P key for 3 seconds to return to normal

mode.

IV. Installation of TPMS1209T02-ER Transmitter

Before install the transmitter, make sure the transmitter has been

programmed into the monitor and monitor is under normal mode. If no

transmitter is programmed or transmitter signal is not received after

Page 13 of 28

program, the screen will display “NSP”.

When the transmitter is screwed onto the valve according to the

programmed position, the monitor can receive the signals and then

display the transmitter location icon, pressure, temperature information

on the screen. When all of information were received by the monitor and

the information are all normal, the screen display “ON”.

1. Installation of Transmitter:

1. Remove the current tire valve cap.

2. Inflate the tire to the standard pressure recommended by the

manufacturer or pressure needed by the user.

Note: Each transmitter has a lock to prevent it becomes loose or falls off.

Install the lock or not will not influence the functions of the

Page 14 of 28

Transmitter. If the user chooses to use the lock, please refer to the

below part of lock installation. Security Lock and Transmitter

should be installed at same time.

3. Screw the transmitter onto the tire valve.

4. Check the connection of Transmitter and valve with the soap solution

to confirm whether the transmitter is firmly screwed onto the valve or

not, check whether there is air leakage caused by the installation or the

seal of the Transmitters or not.

5. Once screwed onto the tire, transmitter can sense the pressure inside

the tire and transmit the data to the monitor, and the information will

appear on the screen within 6 minutes.

Note: 1. Please set the standards pressure of each tire on monitor

before install the transmitter. The standard pressure has

been set to100PSI in factory.

2. If one of your transmitters is broken or lost, the user only

needs to replace this one, the others will work as normal.

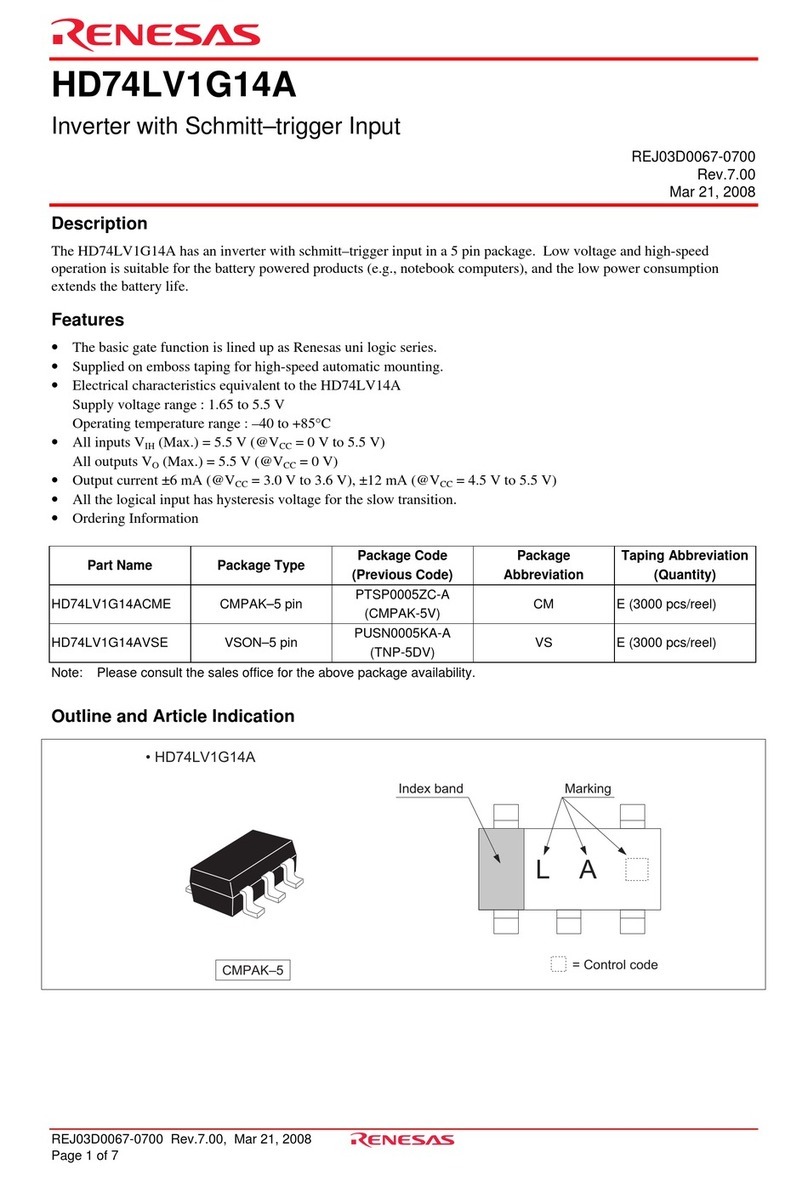

2. Installation of Security Lock

Each transmitter has a security lock and wrench to prevent it becomes

loose or falls off. The security lock has 3 screw holes and each one has 1

screw. As shown below:

Page 15 of 28

The function of the Lock is to connect the Transmitter and the Lock by

connecting the meshing part of them, and then fasten the Lock firmly by

the three bolts in the sockets, thus the Transmitter with the Lock can be

firmly screwed onto the valve and cannot be screwed off by a sudden

force.

Note: Security Lock and Transmitter should be installed at same time. If

the user chooses to use the lock, please refer to the below part of

lock installation.

Installation step of the Security Lock

1. First connect the meshing parts of the Lock and the

Transmitter to make them an integrated part, and

then screw the Transmitter together with the Lock

firmly onto the valve, as shown in the lefet figure.

2. Lock the Transmitter

Use the wrench to fasten the three bolts inside the sockets on the Lock to

Transmitter

Security Lock

Wrench

Page 16 of 28

make sure fix the Transmitter together with the Lock firmly onto the

valve. Then the Transmitter can not be screwed off unless the three bolts

are screwed off by using the wrench.

How to inflate the tire with a locked Transmitter

Before inflating the tire, please

1. Use the special tool to loose the three bolts inside the sockets on the

Lock.

2. Screw off the Transmitter.

3. Remove the Transmitter together with the Lock from the Valve.

Note: Install the lock or not will not influence the functions of the

Transmitter.

V. System Function of TPMS1209T02-ER

1. Full-time Monitoring

Function: TPMS1209T02-ER can monitor the tire pressure and

temperature whether the vehicle is running or parked.

Therefore to keep the driver informed of the tire state and

realize full-time monitoring.

2. High Pressure Alarm

Display mode:

Page 17 of 28

Function: the system will issue the high pressure alarm when the tire

pressure is 25% higher than the standard.

Alarm mode: the alarm lamp flashes, high pressure warning iron, tire

position icon and the audible alarm turn on together.

Treatment: press any key to stop the audible alarm. The red alarm lamp

remains on and the display reverts to the normal mode. At

this time user should adjust the tire pressure to the normal

level with the reasonable method. The red alarm lamp goes

off only when the tire pressure returns to the normal level.

3. Low pressure level 1 alarm

Display mode:

Function: the system will issue level 1 low pressure alarm when the tire

pressure is 12.5% lower than the standard.

Alarm mode: the alarm lamp flashes, low pressure level 1 alarm iron, tire

position icon and the audible alarm turn on together.

Treatment: press any key to stop the audible alarm. The red alarm lamp

remains on and the display reverts to the normal mode. At

this time the user should adjust the tire pressure to normal

level as soon as possible. The red alarm lamp goes off only

Page 18 of 28

when the tire pressure returns to normal level.

4. Low pressure level 2 alarm

Display mode:

Function: the system will issue level 2 low pressure alarm when the tire

pressure is 25% lower than the standard.

Alarm mode: the alarm lamp flashes, low pressure level 2 alarm iron, tire

position icon and the audible alarm turn on together.

Treatment: press any key to stop the audible alarm. The red alarm lamp

remains on and the display reverts to the normal mode. The

user should slow down the vehicle and drive to service shop

to inflate the tire. The red alarm lamp goes off only when the

tire pressure returns to normal level.

5. Low pressure level 3 alarm

Display mode:

Function: the system will issue level 3 low pressure alarm when the tire

pressure is 50% lower than the standard.

Page 19 of 28

Alarm mode: the alarm lamp flashes, low pressure level 3 alarm iron, tire

position icon and the audible alarm turn on together.

Treatment: press any key to stop the audible alarm. The red alarm lamp

remains on and the display reverts to the normal mode. The

user should slow down the vehicle and replace the tire with

the spare tire. The red alarm lamp goes off only when the tire

pressure returns to normal level.

6. High Temperature Alarm

Display Mode:

Function: When the temperature around the transmitter equals or exceeds

90℃, the system will issue the high temperature alarm.

Alarm Mode: the alarm lamp and temperature value flashes, tire position

icon and the audible alarm turn on together.

Treatment: press any key to stop the audible alarm. The red alarm lamp

remains on and the display reverts to the normal mode. The

driver should slow down

and adopt measure to cool down the tire. The red alarm lamp goes off

automatically when the temperature returns to normal level.

7. Fast Leak Alarm

Page 20 of 28

Display mode:

Function: the system will issue a quick leaking alarm when the pressure

drops more than 2.8 psi within 12 seconds.

Alarm mode: the alarm lamp flashes and the audible alarm turns on, the

tire position icon flashes.

Treatment: press any key to stop the audible alarm and the system reverts

to normal mode. Then slow down and check the correspondent

tire.

8. Transmitter Trouble Alarm

Display mode:

Function: If one transmitter fails to work, or the monitor cannot receive

the data because of the RF interference for 20 minutes, the

system will issue a transmitter trouble alarm.

Alarm mode: the audible alarm turns on, the red alarm lamp flashes, and

transmitter trouble alarm icon appears.

Treatment: press any key to stop the audible alarm. Then the system

Table of contents

Other S&T Computer Hardware manuals

S&T

S&T Kontron CP3005 Series User manual

S&T

S&T Kontron SL iMX8MM User manual

S&T

S&T kontron COMe-cWL6 User manual

S&T

S&T kontron KBox E-420-R1K/V1K User manual

S&T

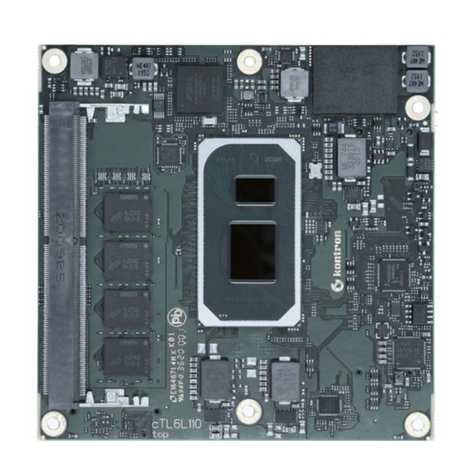

S&T Kontron COMe-cTL6 User manual

S&T

S&T kontron COMe-bCL6 User manual

S&T

S&T Kontron SMARC-sXEL User manual

S&T

S&T Kontron OSM-S i.MX8M Mini User manual

S&T

S&T kontron COMe-cEL6 User manual

S&T

S&T Kontron VX3060 User manual