3

Table of Contents

INSTRUCTION MANUAL ............................................................................................................. 1

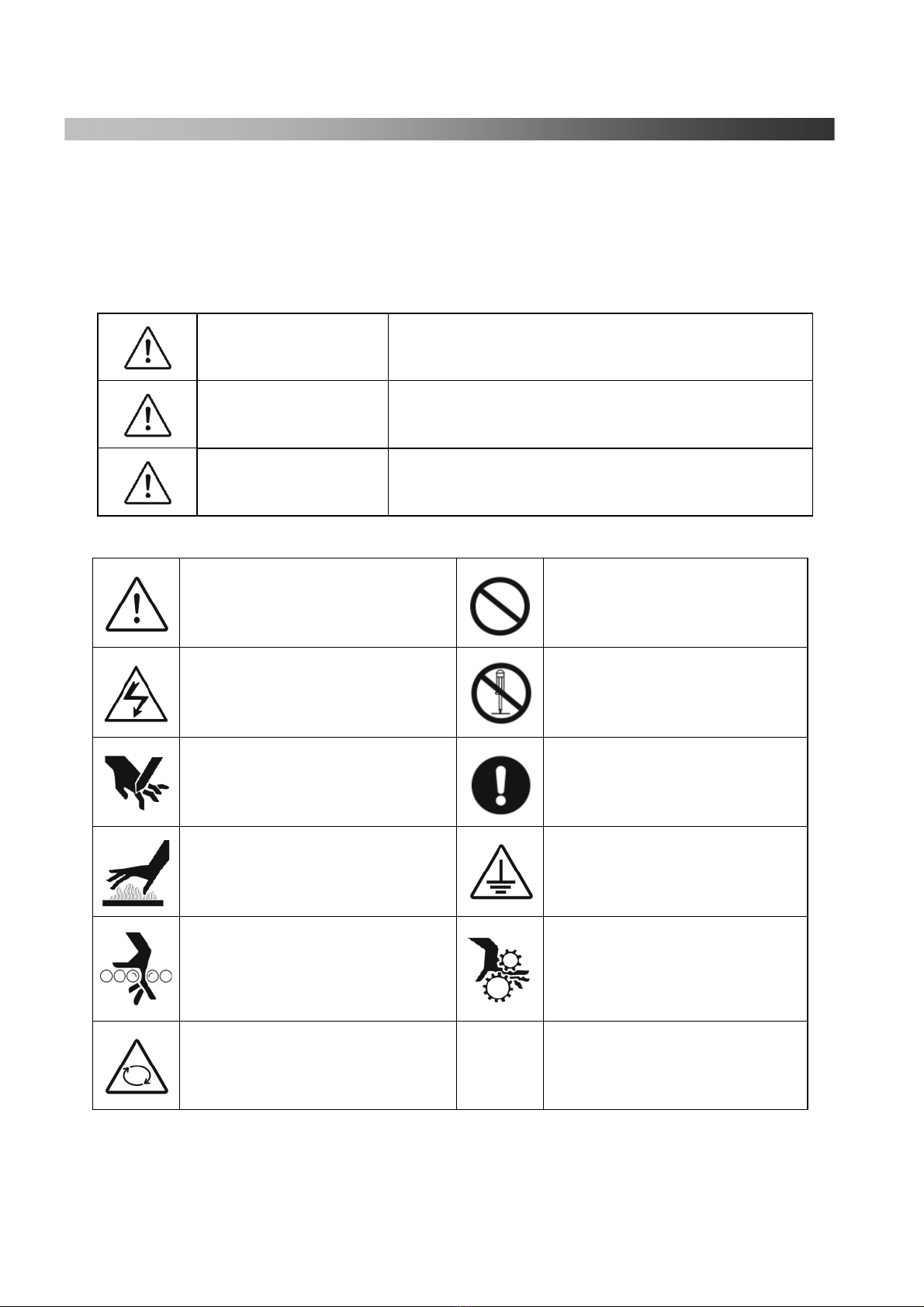

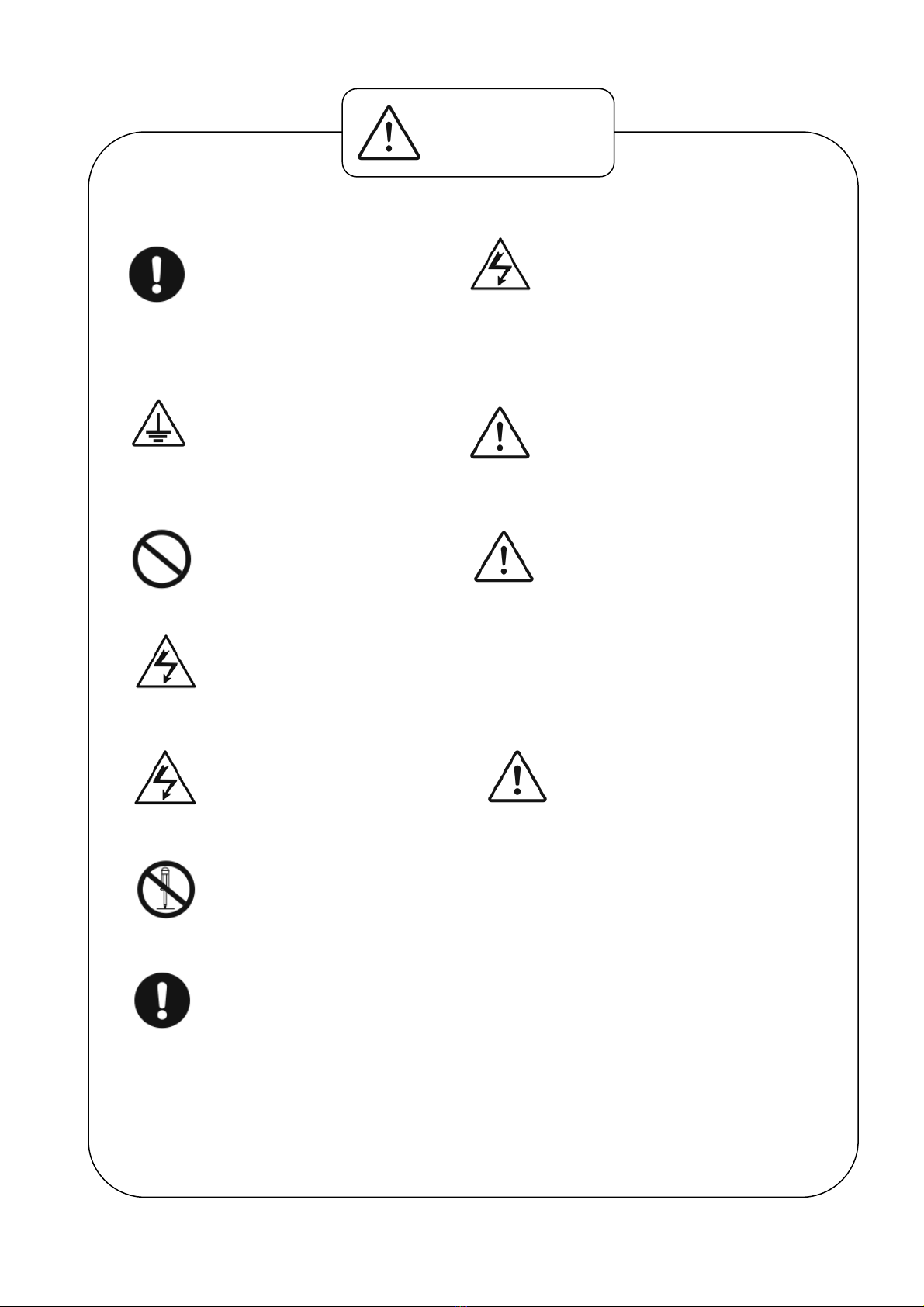

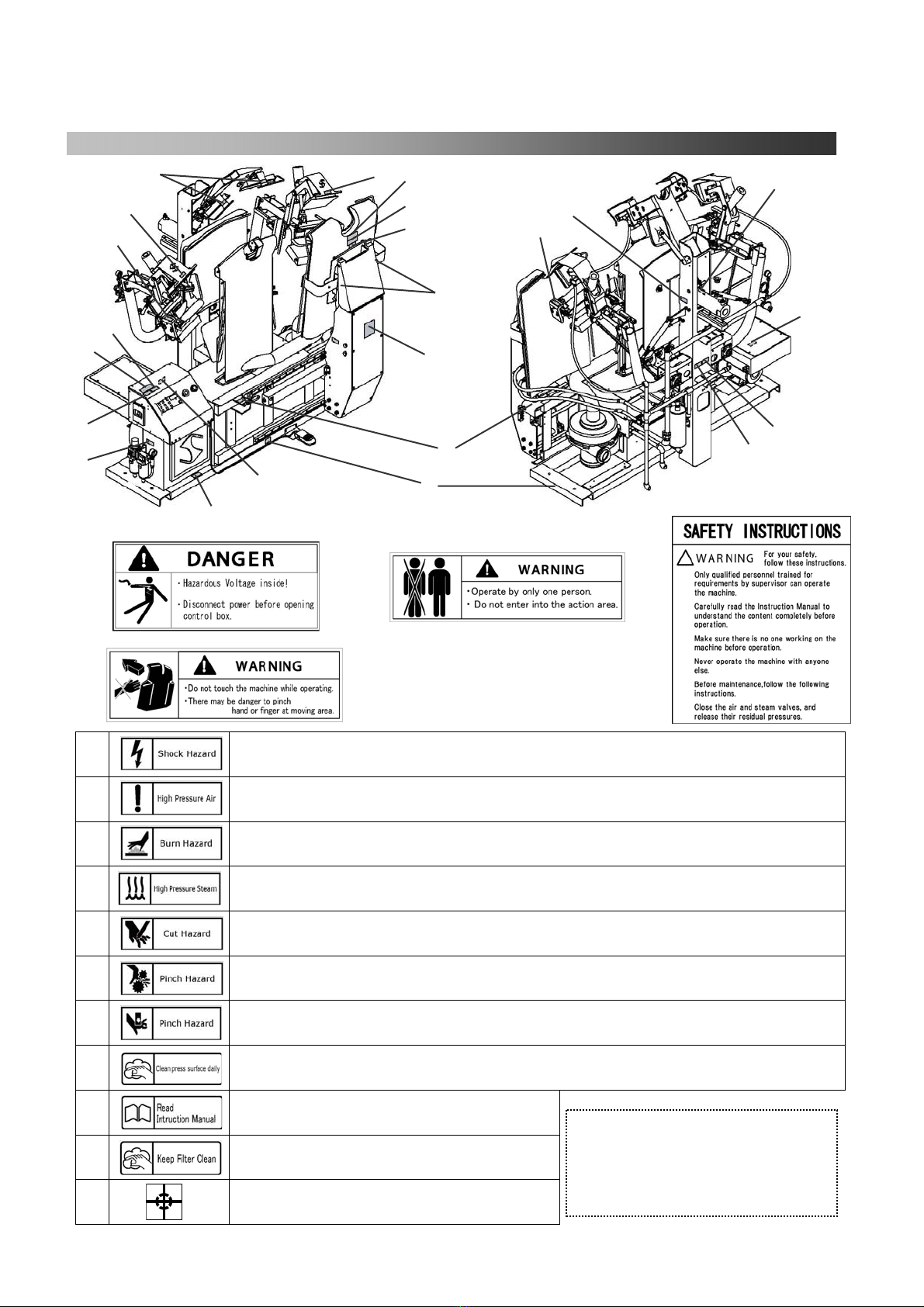

Safety Guidelines .............................................................................................4

Hazardous Area ...............................................................................................7

Electrically Live Area ....................................................................................................... 7

Machine Moving Area ...................................................................................................... 8

High Temperature Area .................................................................................................. 9

Safety Labels on the Machine.........................................................................10

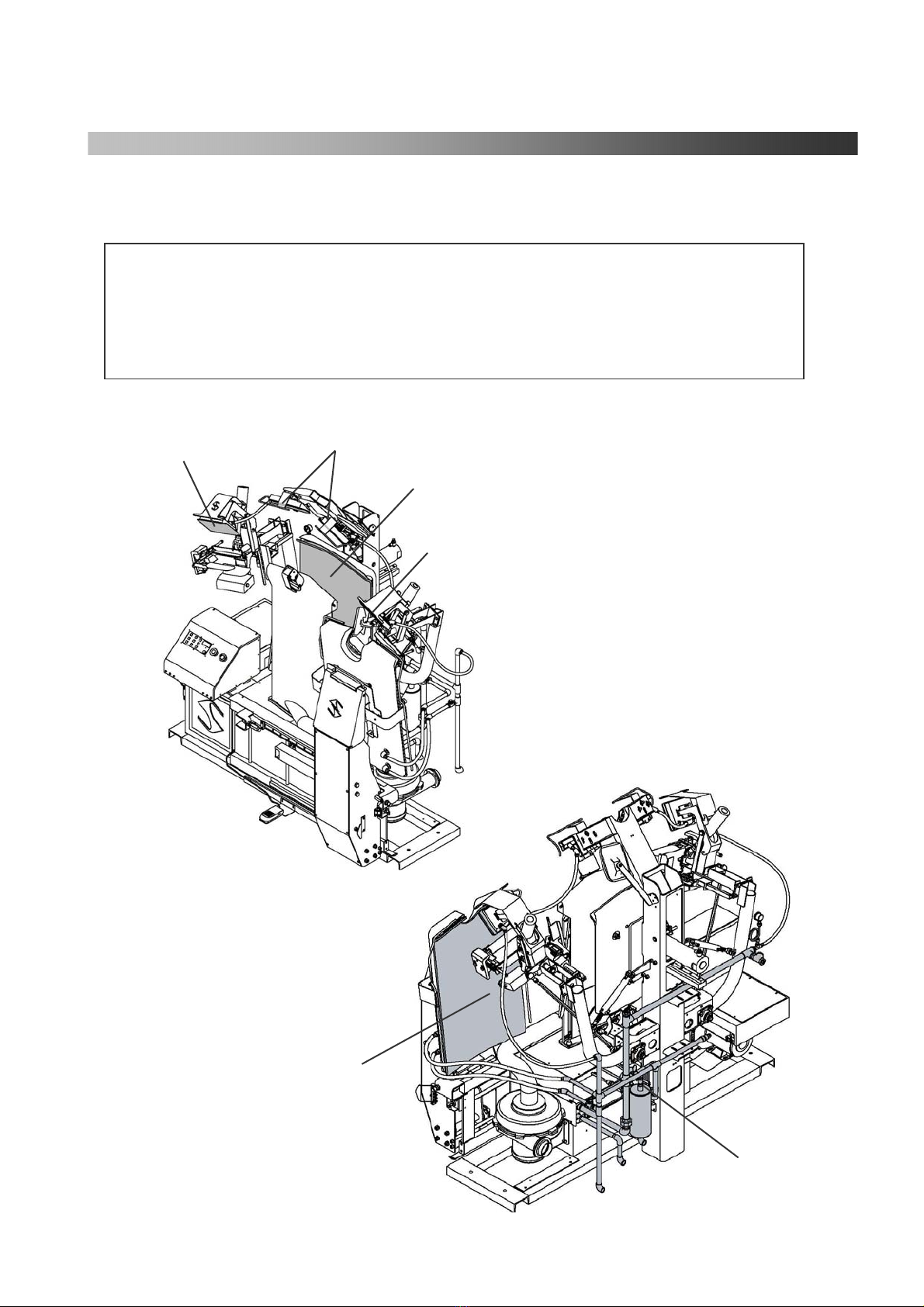

Main Devices..................................................................................................11

Control Unit...................................................................................................12

Control Box .......................................................................................................................... 12

Operation Box .................................................................................................................... 14

Operation Procedures ....................................................................................15

Provide Air ........................................................................................................................... 15

Provide Steam ..................................................................................................................... 16

Turn the Power On ........................................................................................................... 16

Press Warming Up Button..........................................................16

Set each timer according to the material of the shirt................17

Set the Shirt ......................................................................................................................... 18

After Operation Is Over ................................................................................................ 26

Other Operations...........................................................................................27

How to Reset Emergency Stop (Safety Error) ............................................. 27

About the Cover Counter .......................................................................................... 27

How to Replace the Cover & Padding.............................................................28

Tail Clamp ............................................................................................................................ 28

Body ......................................................................................................................................... 29

Neck Clamp ......................................................................................................................... 32

How to Install the Cuff Clamp Cover, Front & Rear Tuck Cover and

Short Sleeve Cover ........................................................................................................... 32

Test Operation ...............................................................................................33

Service Menu.................................................................................................36

Trouble Shooting............................................................................................42

DAILY MAINTENANCE............................................................................................................... 48

Check Item List .............................................................................................48

Check Item (Daily).........................................................................................49

Check Item (Monthly)....................................................................................51

Check Item (Annual)......................................................................................51

Item Check List .............................................................................................52

SPARE PARTS LIST ........................................................................................................................ 53

Motor Operation Diagram .............................................................................54

Air Piping (1).................................................................................................56

Air Piping (2).................................................................................................58

Air Piping (3).................................................................................................60

Steam Piping..................................................................................................62

Control Box・Switch Diagram.......................................................................64

Cover Diagram ..............................................................................................66

ATTACHED DIAGRAM ................................................................................................................ 68