Sansui P-M7 User manual

Other Sansui Turntable manuals

Sansui

Sansui SR-222 User manual

Sansui

Sansui SR-636 User manual

Sansui

Sansui FR-4060 User manual

Sansui

Sansui SR-9219 User manual

Sansui

Sansui SC-3300 User manual

Sansui

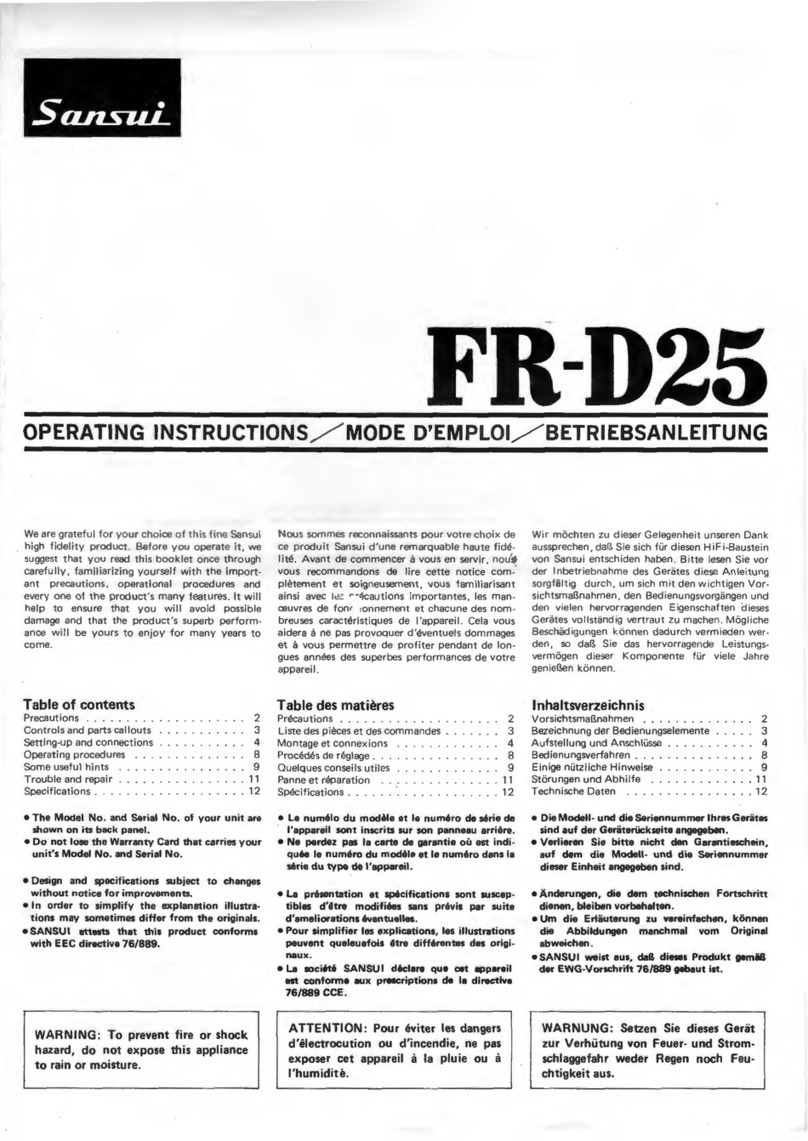

Sansui FR-D25 User manual

Sansui

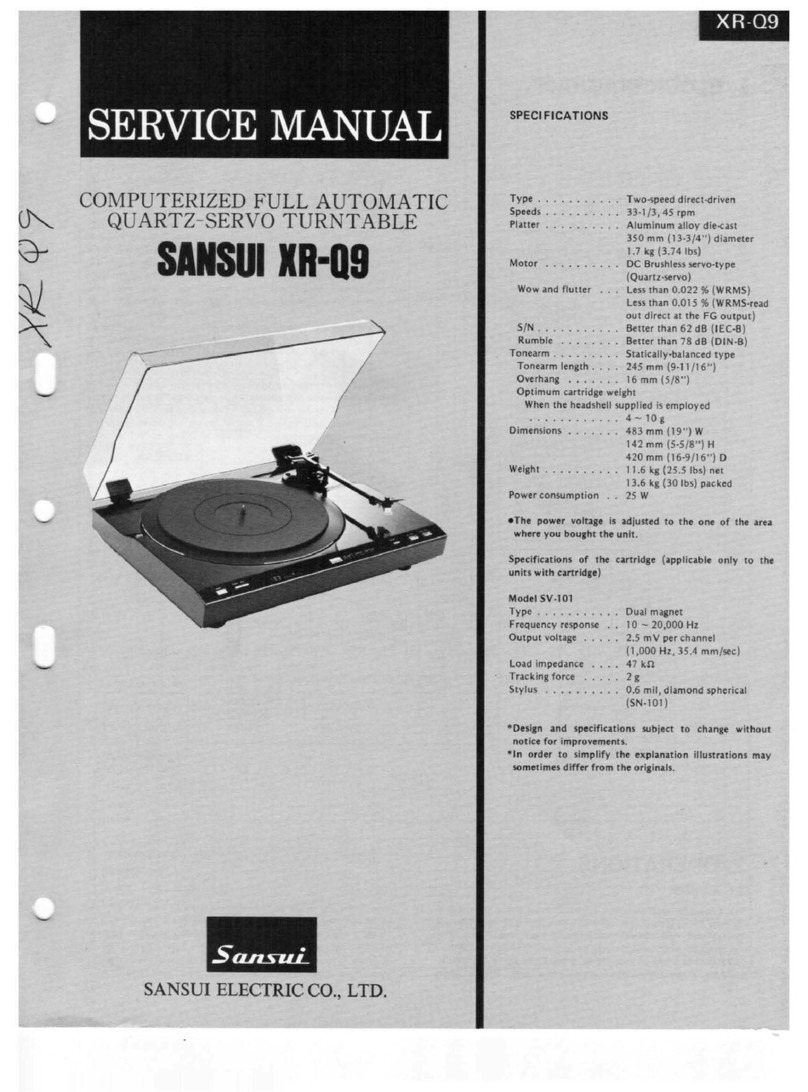

Sansui XR-Q9 User manual

Sansui

Sansui DA-P500 User manual

Sansui

Sansui SR-212 User manual

Sansui

Sansui SR-222MKV User manual