Santint

PA Series Paint Mixing Machine V1.1 2

Contents

1. Introduction……………… …… ………… …… ……… …… ………… …… ………… .1

2. Circuit Diagram…………………………………………………………………………….1

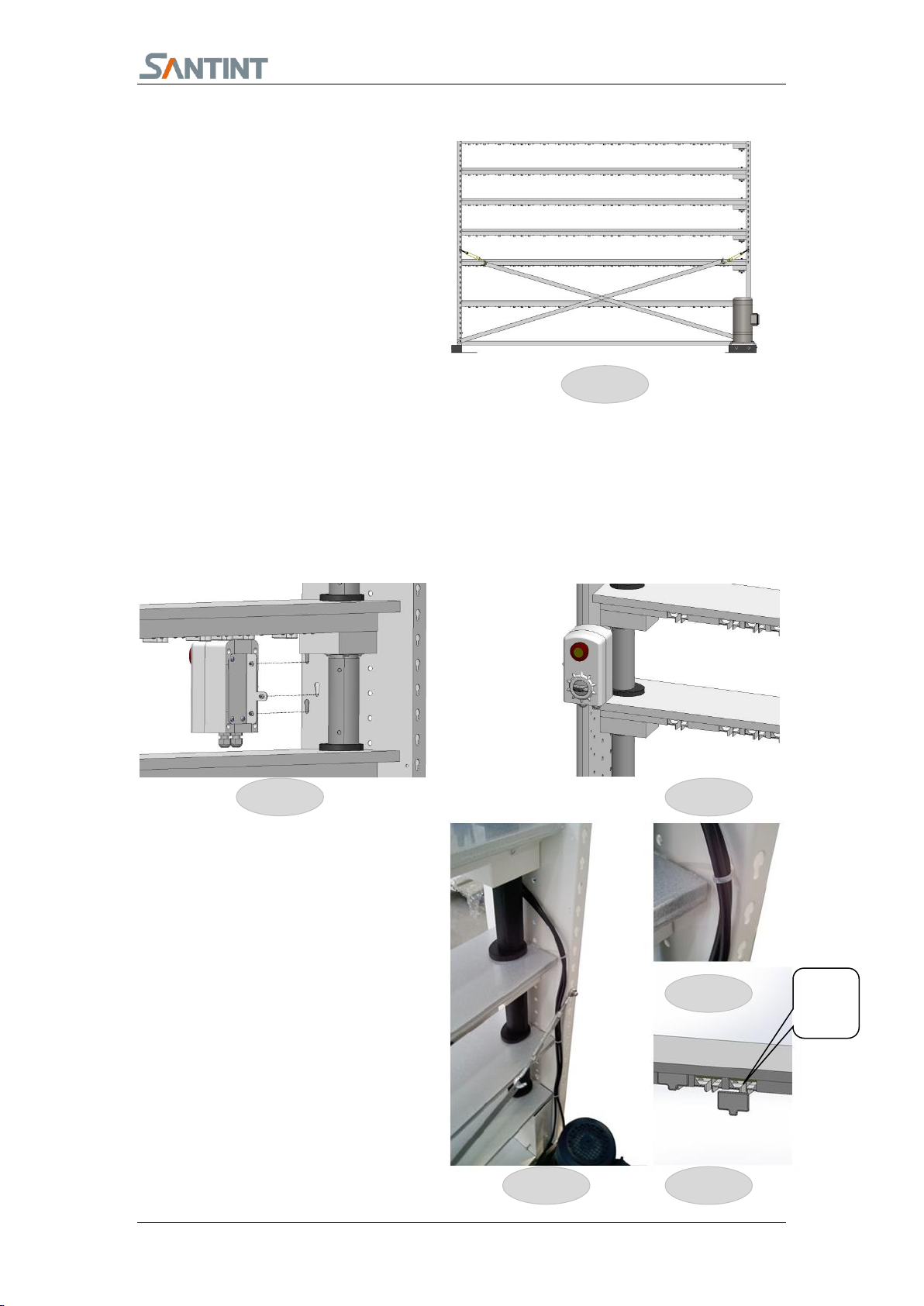

3. Technical Parameters………………………………………………………………………2

4. Setup Preparation………………………………………………………………………….2

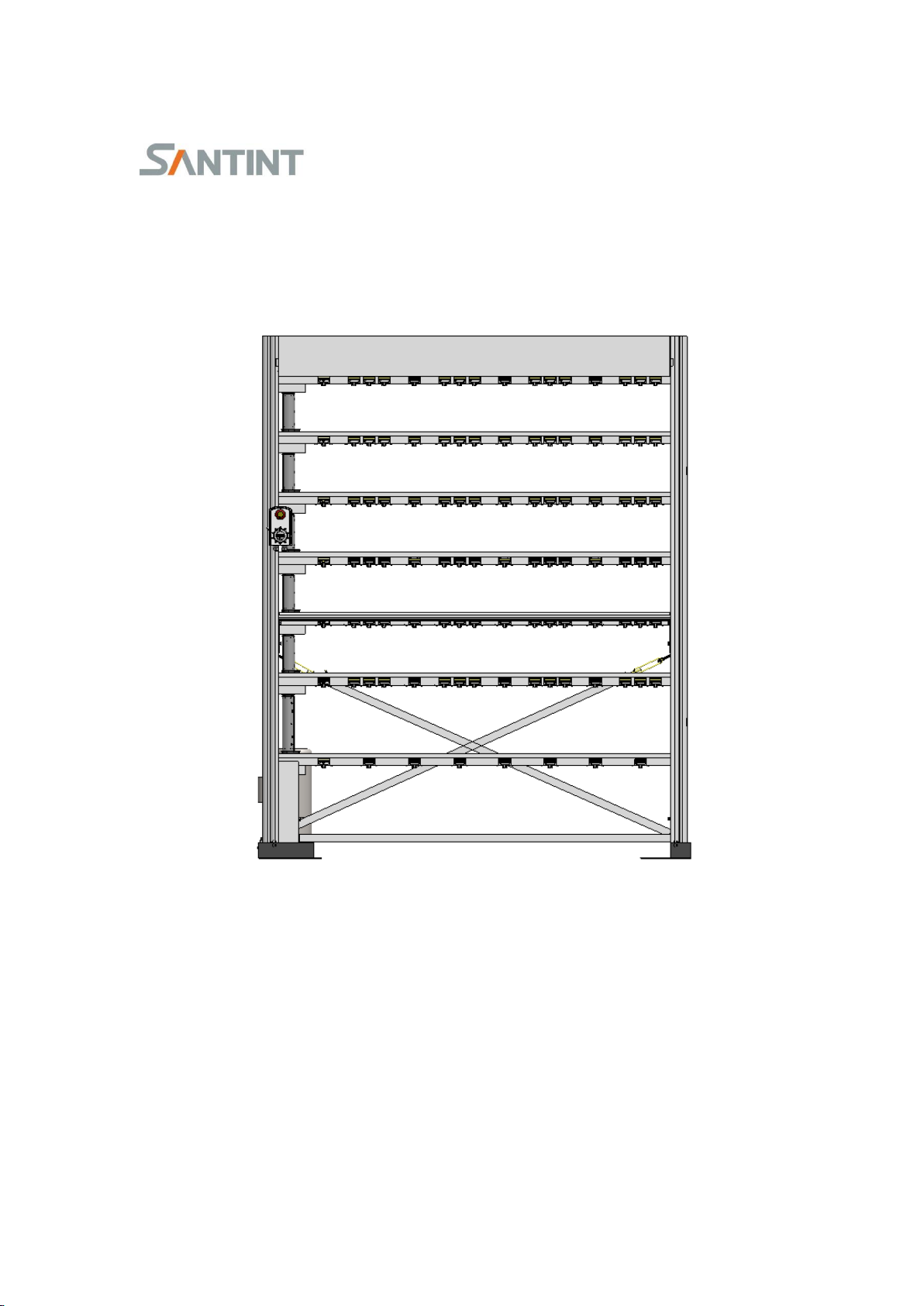

5. S e t u p ……………………………………………………………………………. 2

5.1 Spare Parts………………………………………………………………….………...2

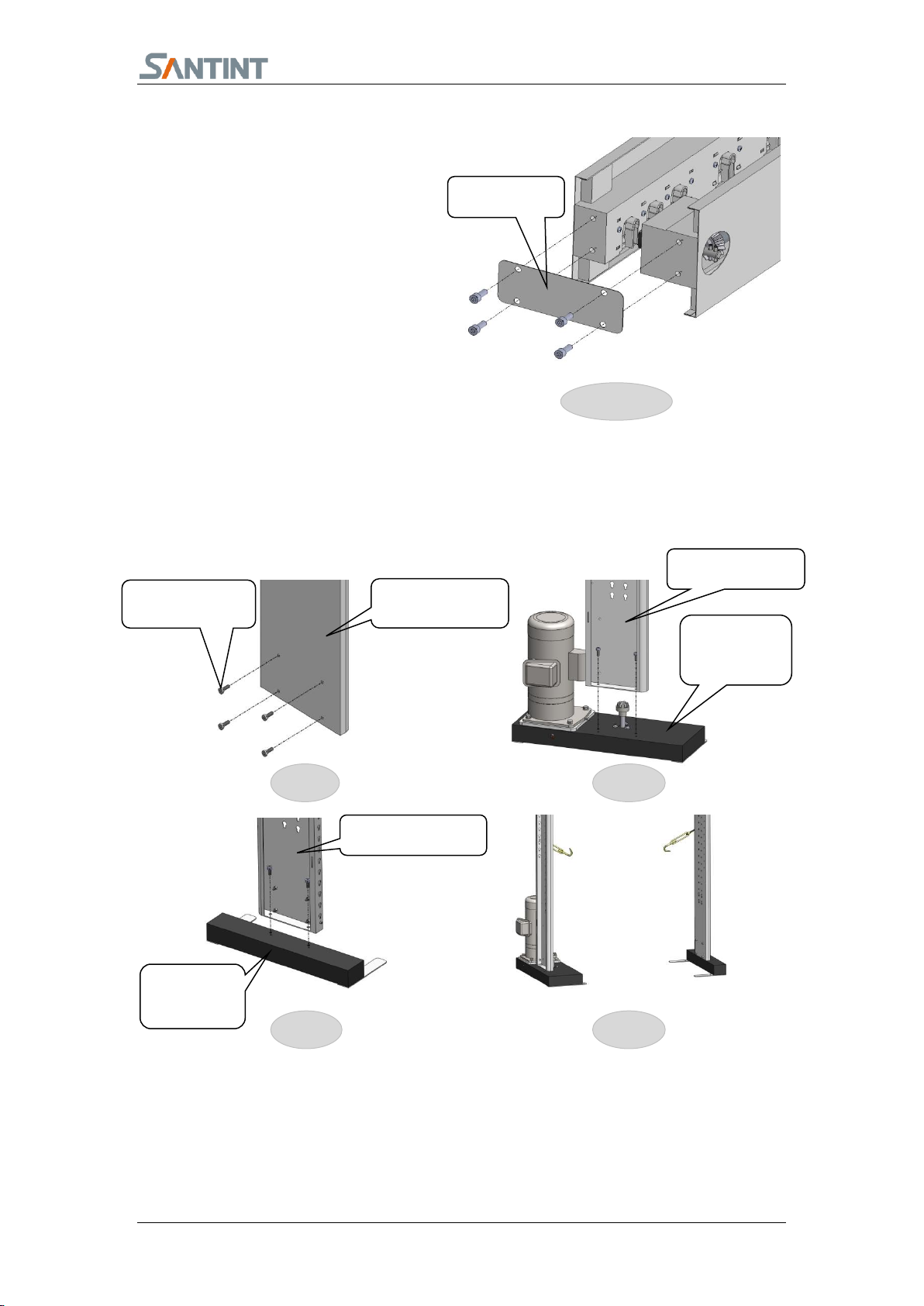

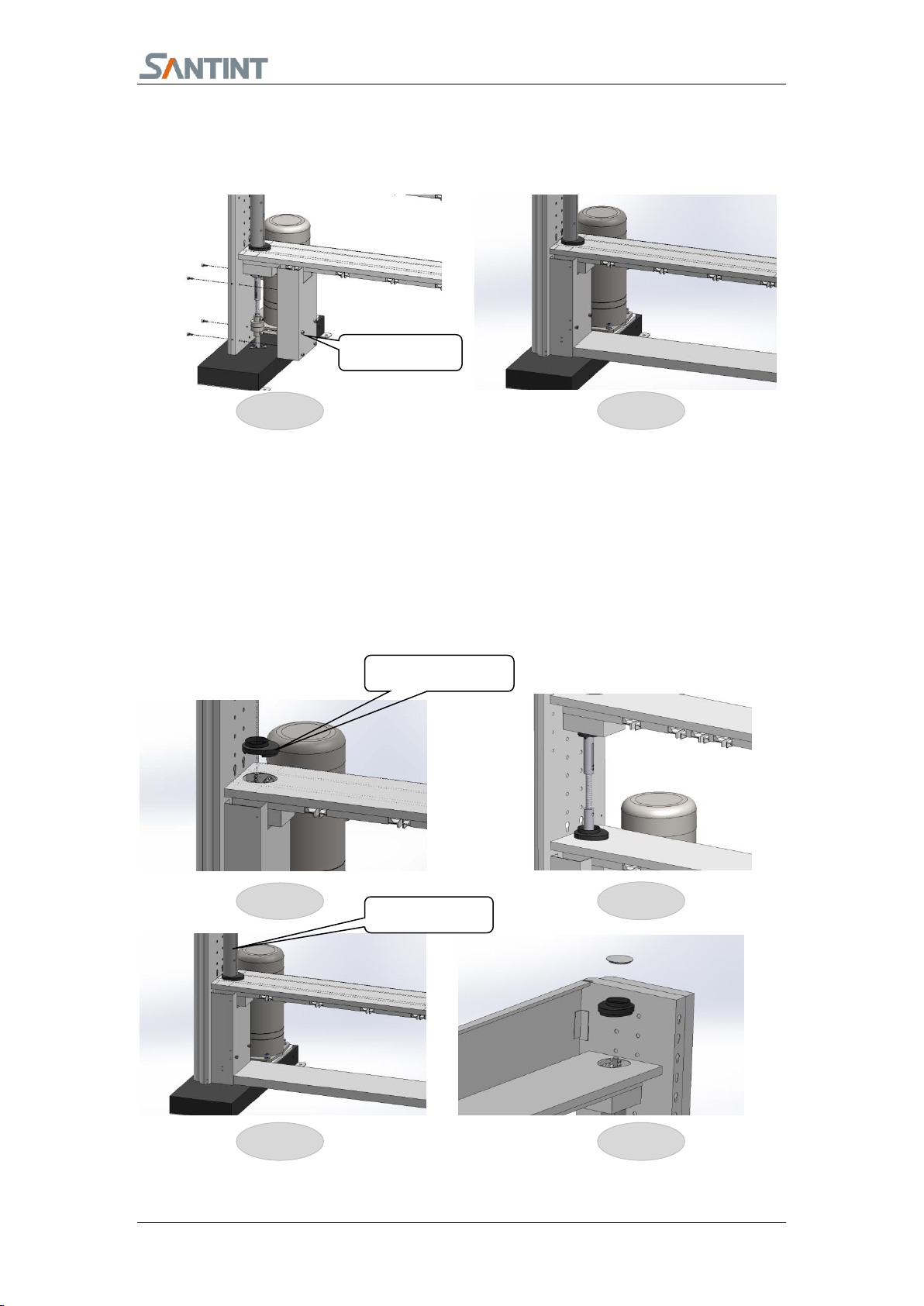

5.2 Installation Process …………………………………………………………………3

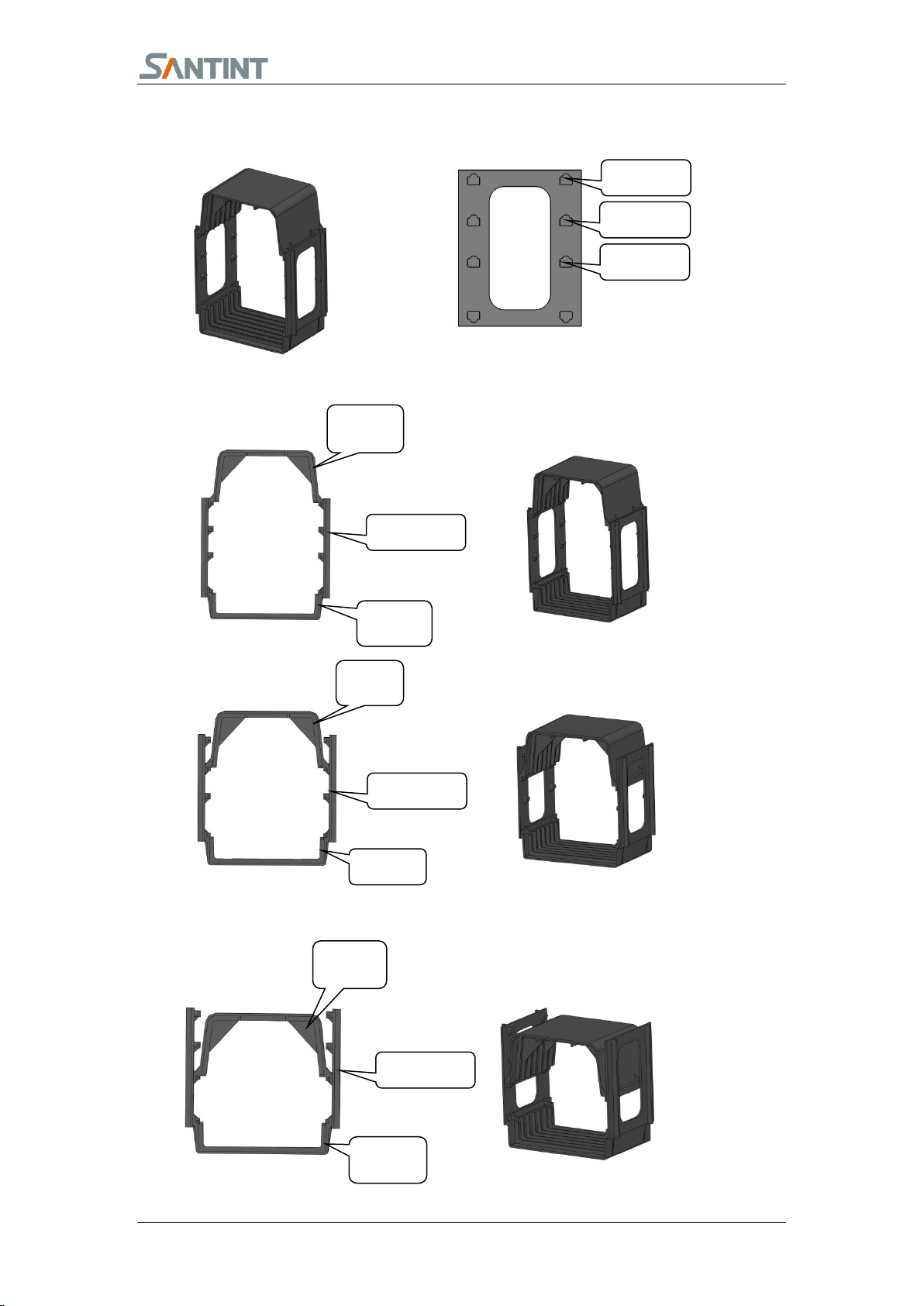

5.3 Installation Process of Operational Parts………………………………………………9

5.3.1 Platen…………………………………………………………………………9

5.3.2 Left/Right Hanging Plate………………………………………………………9

5.3.3 Back-storing Shelf and Mica Shelf…………………………………………10

6. U s a g e …………………………………………………………………………….11

6.1 Check-up Before Usage………………………………………………………………11

6.2 Operation…………………………………………………………………………12

7. Troubleshooting…………………………………………………………………………12

8. R e p a i r …………………………………………………………………………….13

8.1 Tension the Chain……………………………………………………………………13

8.2 Replace the Spring Pin and Jackscrew………………………………………………13

8.3 Replace the Plastic Cone-Gear Assembly…………………………………………13

8.4 Lubrication…………………………………………………………………………14

9. Maintenance…………………………………………………………………………….14

9.1 Daily Maintenance………………………………………………………………14

9.2 Maintenance for Long Time No Use……………………………………………………14

10. Nameplate…………………………………………………………………………….15