–9 –

4. When the measurement object has resistance of more than 2000

MΩ, the LCD shows the same over-input display as that displayed

when the measuring terminals are open, as shown in Fig. 1 under

section [4]4-2, “Checking the Built-in Batteries” on page 6.

5. After measurement, press the POWER switch again to OFF or

set the function switch to OFF.

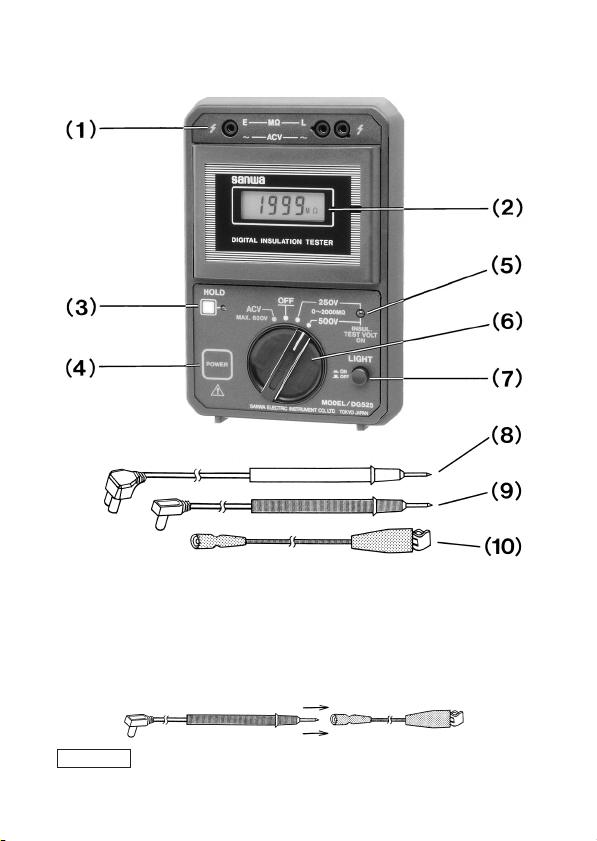

NOTE: Distinction Between E and L Terminals

When one of the measuring points is grounded, connect it to the E

terminal of the instrument.

This is specified in consideration of safe use, because the resis-

tance measurement value reading in the insulation testing can be

reduced in this way. In other measurement operations, consideration

of the polarity of measurement points is not necessary.

NOTE: In Case the “B” Marking is Displayed During Measurement

When the resistance measurement value in an insulation test is

extremely small, the LCD sometimes shows the “B” marking which

is usually used as the battery alarm indicator.

In the present case, the “B” marking is displayed because an

extremely small resistance measurement value means consumption

of large battery current and the drop in capacity due to exhaustion

of the batteries causes the internal operating voltage to fall below

the specified level.

4-5 Measuring the AC Voltage (ACV)

1. The maximum allowable input voltage of the ACV range is

600 V. Never apply a higher voltage than this.

2. Voltages higher than 25 Vrms AC are hazardous to the

human body. Be very careful during measurement.

3. Never attempt to change the function switch position

during measurement.

4. Never measure AC voltage with a wet hand.

WARNING