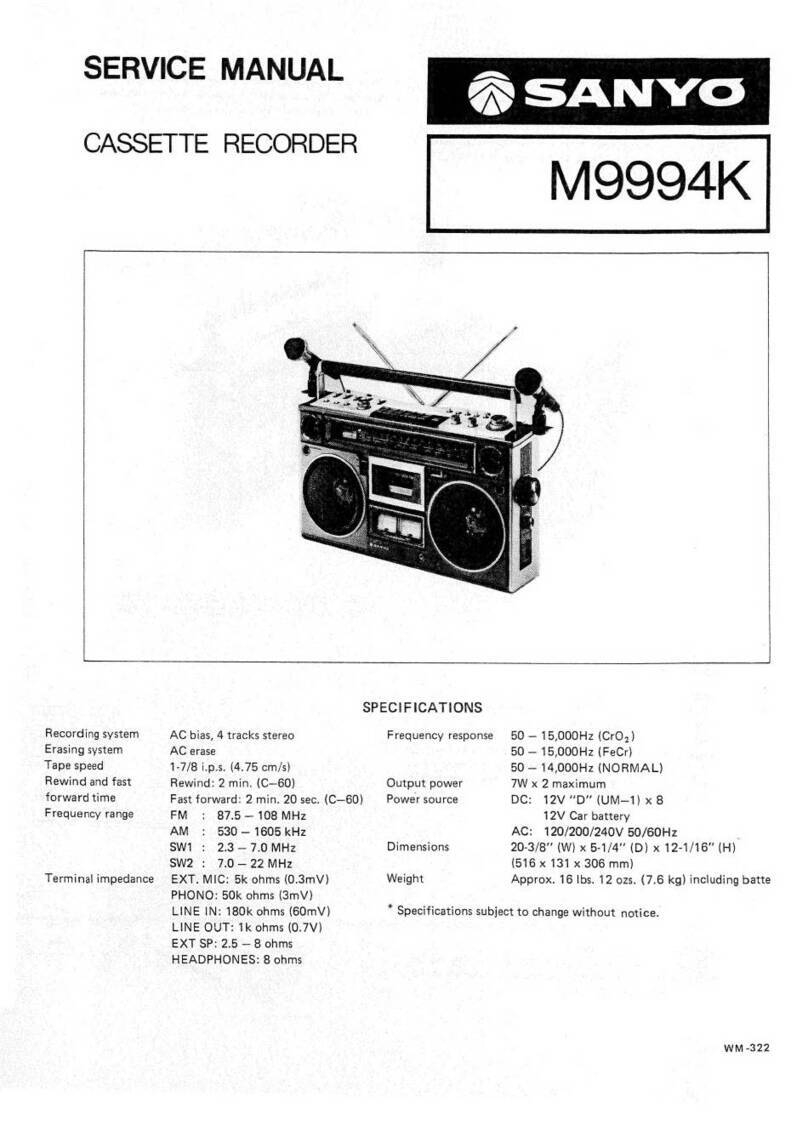

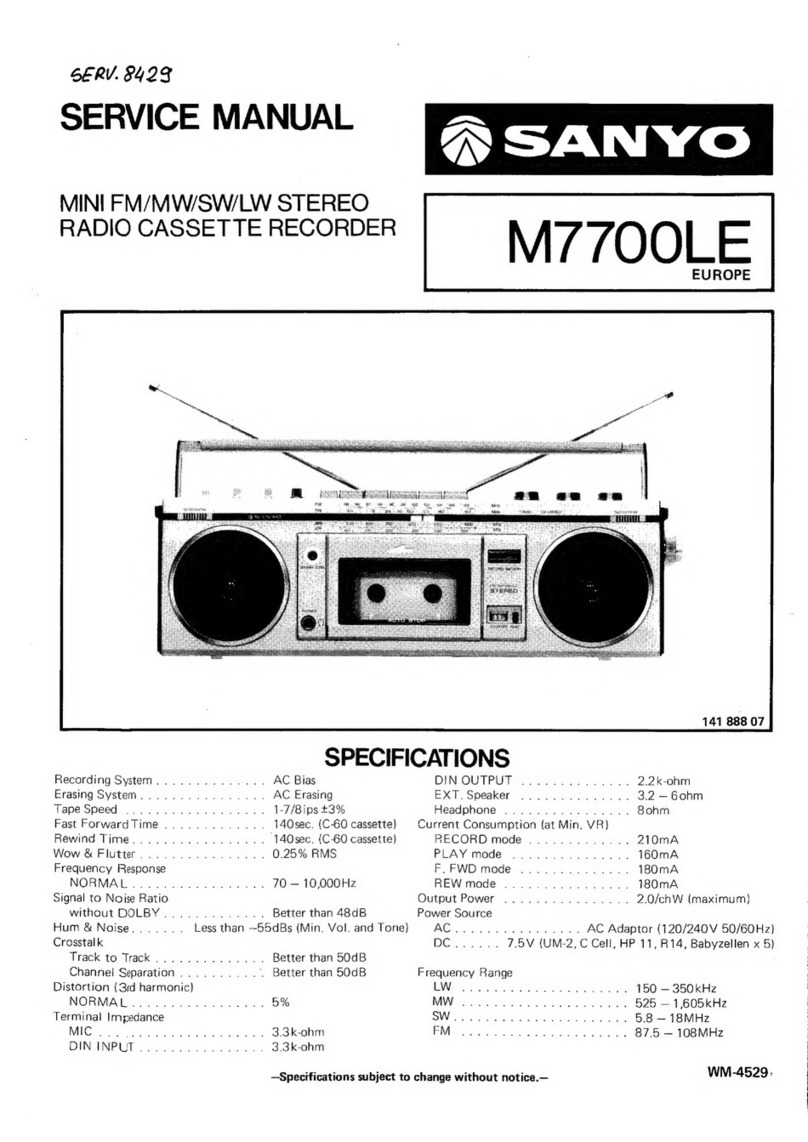

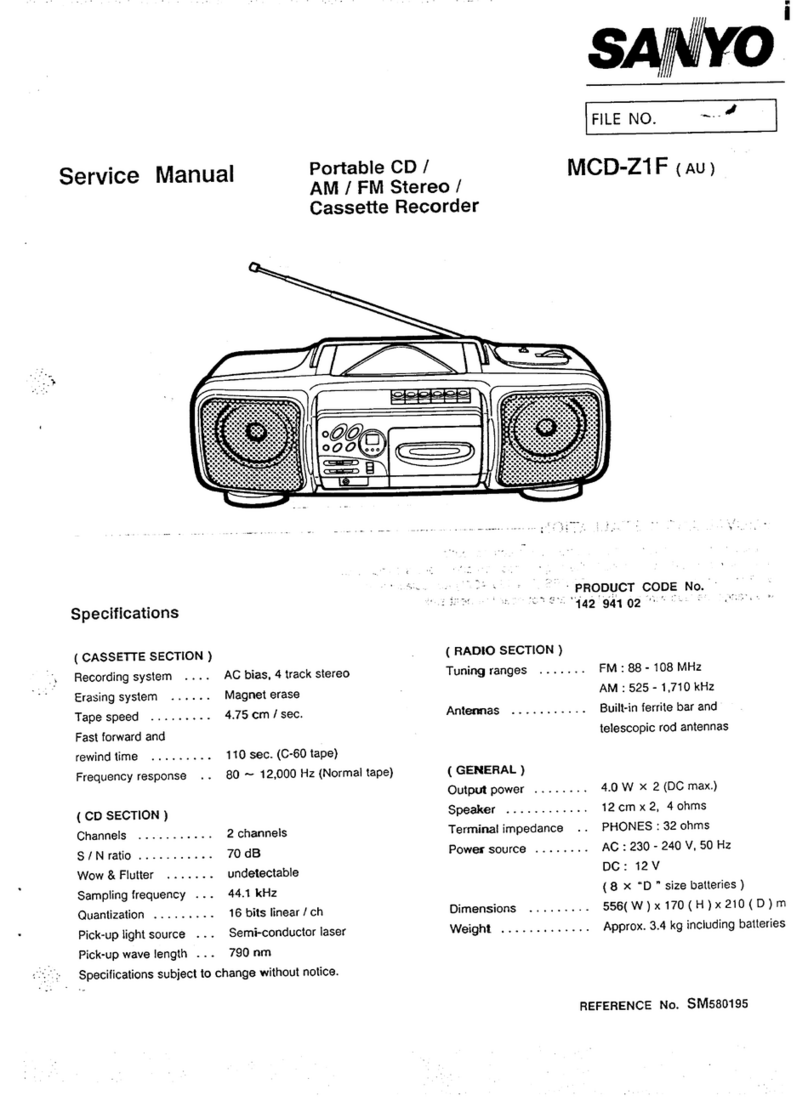

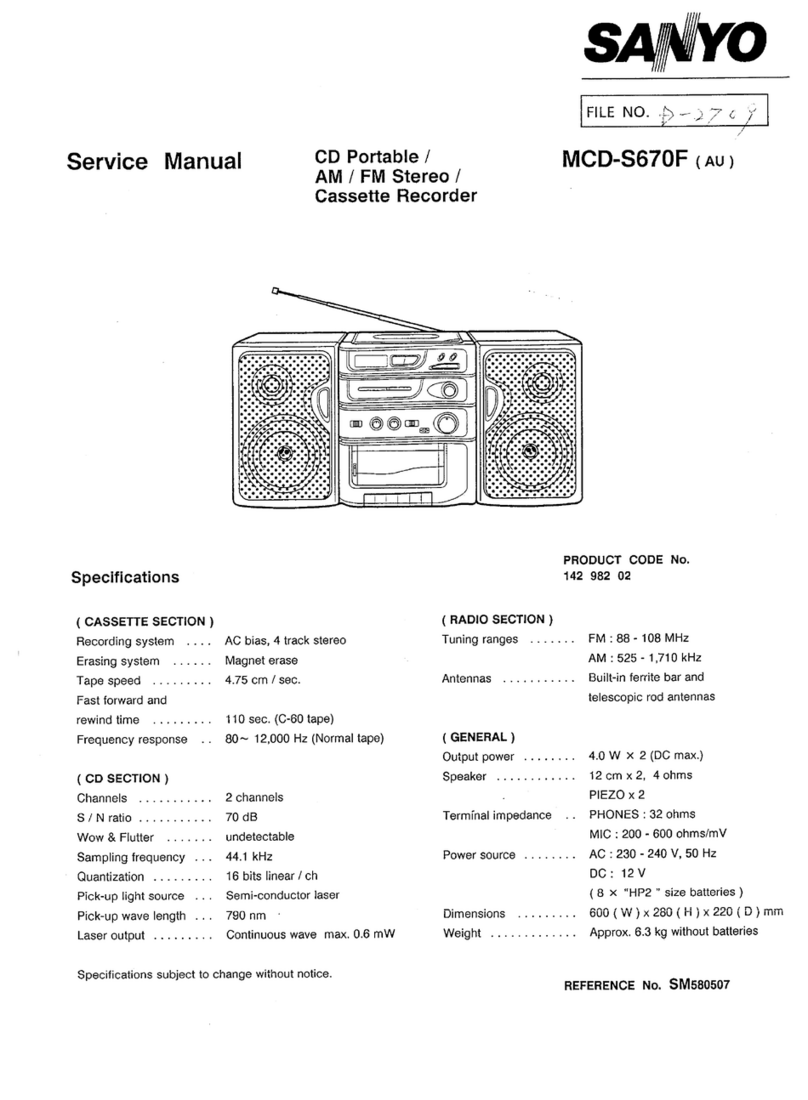

SERVICE

MANUAL

STEREO

RADIO

CASSETTE

RECORDER

Power

Source

PG

Ss

Since

tak

aieets

Salome

Meme

shal

ae

aS

120V/210V/240V

(50/60Hz)

DG

i

tein

cauistuavedttoameeout

une

een

10.5V

(UM-2,

HP

11,

C

Cell,

Babyzelle,

R

14)

x7

QOULPUL

POWER

5:

isis

tenons

sentcmsans

ewes

AW

x

2

(Max.)

Power

Consumption

............cce0eeeees

13W

Current

Consumption

(at

Vol.

Min.)

Record

mode

(with

Metal)

..............

260mA

Playback

mode

..............ccceee

eee

e

es

210mA

Fast

Forward

mode

................020065

210mA

Rewind

mode

..............cceeeeeeeeeees

210mA

Recording

System

............cccceseeeeees

AC

Bias

Erasing

System

...............cceceeeeeeees

AC

Erasing

TAP@

SPO

on.

cceccec

ces

sdenscensenntancece

1-7/8ips.

+3%

WOW:

Sc

FIUTED

oSseccau

dant

semslevs

sae

velesoutee

0.15%,

WRMS

Fast

Forward

Time

...............c0c0s0ees

130sec.

(with

C-60)

REWING

TIME

«2s

cicccsesdesevodenveeiconsess

130sec.

(with

C-60)

Torque

Playback

...................

i

30

~

65g-cm

Fasthorward)

sscoscsssactedinces

aie

akasaws

&

55

~

180g-cm

FROWA

A

Givcscrteccecwisrsjiidiose

rnieid

stersiersoteeeisniatanceiat

«

55

~

180g-cm

Erase

Ratio

(Overall,

with

Fe2Os)

.......

60dB

Signal

to

Noise

Ratio

(with

Fe2Oa)

......

45dB

Channel

Separation

(with

Fe2O3)

.......

45dB

AC33

142

38002

SPECIFICATIONS

—Specifications

subject

to

change

without

notice.—

Frequency

Response

(Overall)

FOZ

Og

sca

sresiee

ne

ceescets

cis

tates

walaethuaresciate

50Hz

~

13,000Hz

GQ

2.

cecies

secu

eee

etaerisen

cba

Saws

50Hz

~

14,000Hz

Metale

cctscccsatisiemantinne

steno

eee

onion

50Hz

~

15,000Hz

Crosstalk

(with

Fe2Os)

MACK

TOMMACK

cies

ad

ties

ond

dasa

maces

sears

60dB

Harmonic

Distortion

(K3,

with

Fe203)

..

3%

Hum

&

Noise

(at

Vol.

Min.)

................

—65dBs

Input

Sensitivity

and

Impedance

NAICS

sesorecians

ate

srttturcroe

BOE

nat

eal

aes

arse

aerate

0.3mV/3.9kO.

LINEN

acnjaedtaticoends

deat

eimaabaiuciinten

300mV/100k0,

Output

Level

and

Impedance

LINE

QUT

Sindee,

waccus

semomnancocaad

xiao

550mV/2.2k0,

EXE

SPOAKOR

basis

sssesciore:csarejsieieinierneiieseerccetenere

3,200mV/3.20,

Head

Phone

sservaeccarsiocnuaseentaondtad

3,900mV/320

Oscillation

Frequency

.................065

60kHz

Frequency

Range

MW

ist

cteottisher

enn

sieedoanadeannee

saemacia

525

~

1,605kHz

SW

Karns

oeariatrarc

nate

Saaeneeredt

andes

2.3

~

7.3MHz

SW)

Fisnoteciated

tasdoeeantelenaee

Sena:

7.3

~

23MHz

FAME

oe

views

svastestrataausaions

auconnawtnaatesnetens

stoaates

88

~

108MHz

DIMENtONS

wssicsnuieoscertecoens

437(W)

x

137(H)

x

99(D)mm

Weighti:

mccasstae.

cerscsctonaccsaecutecaceen

2.5kg

©

WM-9533

JGSE2B